Wall-climbing robot supporting arm assembly

A wall-climbing robot and arm assembly technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of low connection strength and low firmness, and achieve the solution of low connection strength, high self-strength, and relatively firm firmness. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

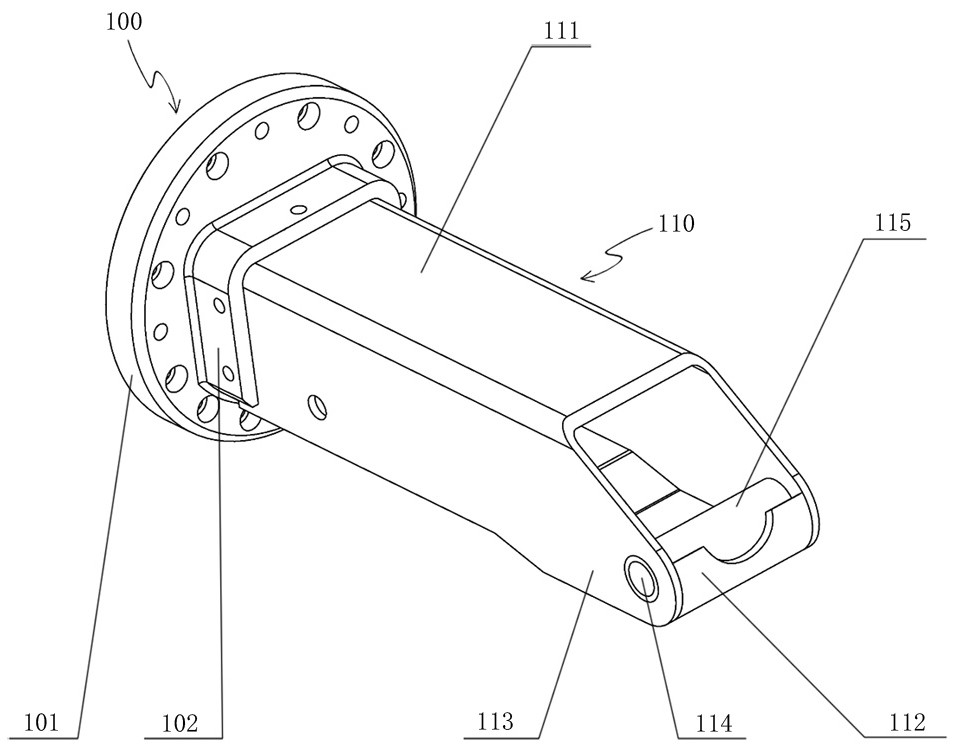

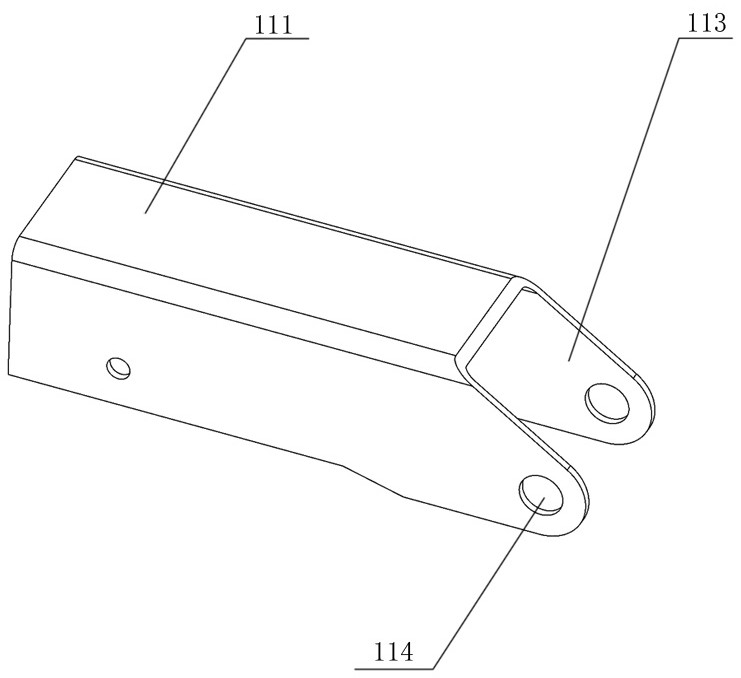

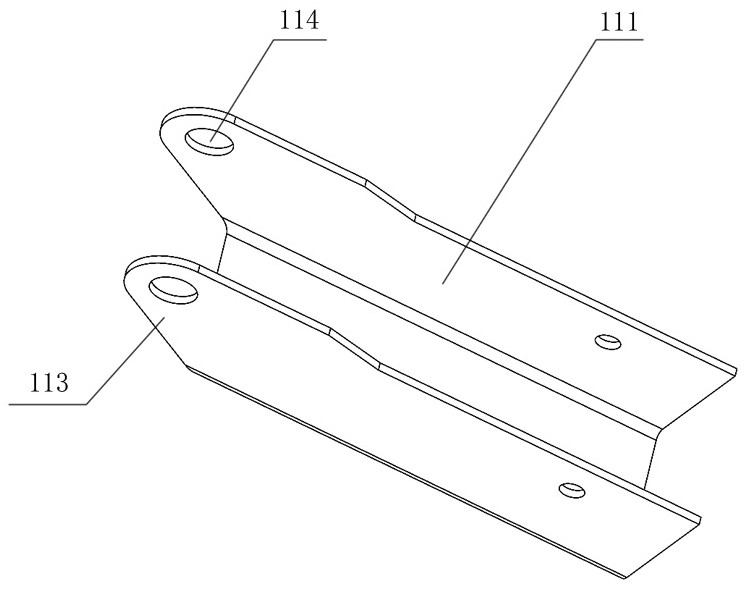

[0011] Such as figure 1 As shown, the present invention includes two components of the arm body 110 and the connecting flange 100 . The arm body 110 includes a channel-shaped arm beam 111 and a sealing plate 112 welded on the notch of the channel-shaped arm beam. Such as figure 2 , image 3 As shown, the trough support beam 111 is a square trough elongated structure ( image 3 ), the connecting end with the connecting flange 100 is a door-shaped flat port, and the connecting end with the robot frame is the protruding end 113 ( figure 2 ), there are circular holes 114 respectively on the two protruding ends 113, the size of the two circular holes 114 is the same, and the centers of the circles are opposite, a shaft sleeve 115 can be set between the two circular holes, and the pin shaft passes through the circular holes 114 and the shaft Cover 115, and then through the robot frame, the articulated connection of the robot support arm and the robot frame can be realized. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com