Special lifting frame for heating plate for wood heat treatment

A wood heat treatment and heating plate technology, applied in the field of special hangers, can solve problems such as difficult operation, inability of suction cups to close the heating plate tightly, hidden dangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

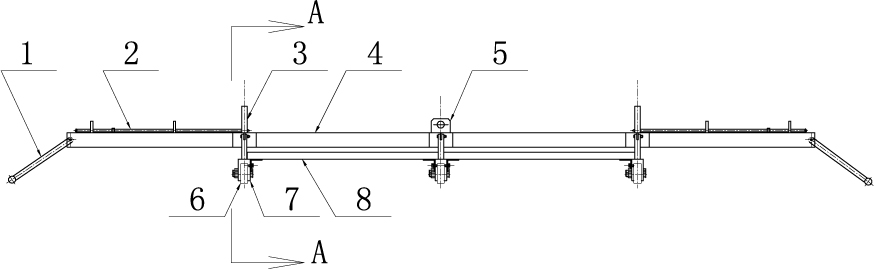

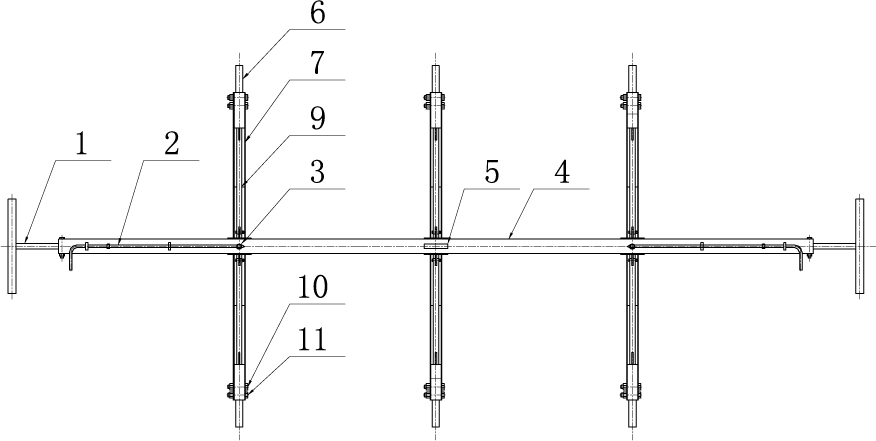

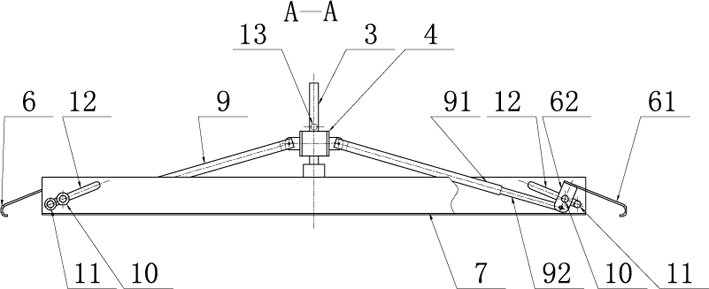

[0018] Such as figure 1 , figure 2 , image 3 As shown, the special hanger for the heating plate of the wood heat treatment of the present invention comprises at least two crossbeams 7, and a longitudinal suspension beam 4 that can be vertically lifted on the crossbeam is provided above the center of the crossbeam length direction, and a vertical suspension beam 4 is arranged on the longitudinal suspension beam. A hook frame 5 is arranged, and an operating handrail 1 is provided at both ends of the longitudinal suspension beam. A vertical guide column 3 is provided at the center of the upper surface of the beam, a vertical guide hole matched with the vertical guide column is provided on the longitudinal beam, and a vertical guide hole is provided on the longitudinal beam to prevent the vertical beam from sliding upward along the vertical guide column. The guide column lock pin 2 is provided with a guide column limit lock hole 13 matched with the lock pin on the guide column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com