Device for heating ball head pin and use method thereof

A ball stud and heating ring technology, applied in the field of steel quenching, can solve the problems of inconvenient insertion or removal of the ball stud, low safety, and injury to workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

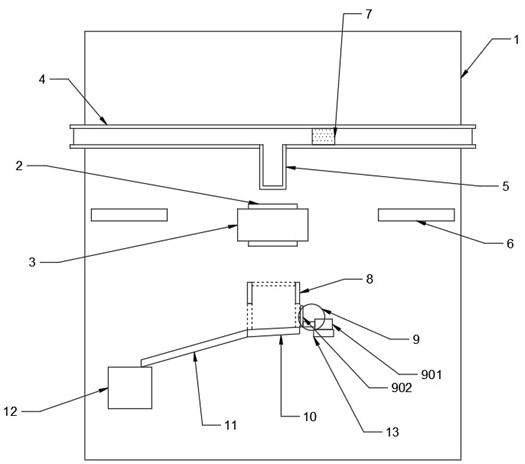

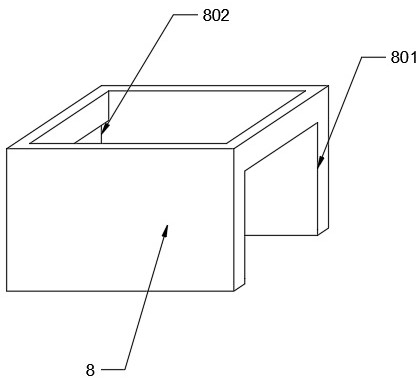

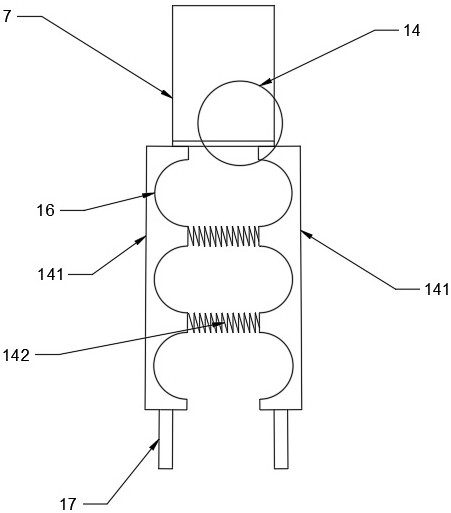

[0037] Such as Figure 1-Figure 4 As shown, the device for heating the ball stud provided by this embodiment includes

[0038] The main body 1 of the high-frequency induction heating machine, the wire 2 connected to the main body 1 of the high-frequency induction heating machine, and the heating ring 3 fixed at one end of the wire 2 for heating the ball pin, the heating ring 3 has a rounded rectangular structure;

[0039] The first track 4, the first track 4 is arranged on the outside of the high-frequency induction heating machine main body 1, and the bottom of the first track 4 is provided with a second track 5, the two are perpendicular to each other, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com