Dry hanging structure of assembled PP ceramic tile inside corner

A prefabricated, ceramic tile technology, applied in building structure, floor, covering/lining, etc., can solve the problems of poor installation effect and difficult installation, and achieve the effect of high installation efficiency, good installation quality and high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

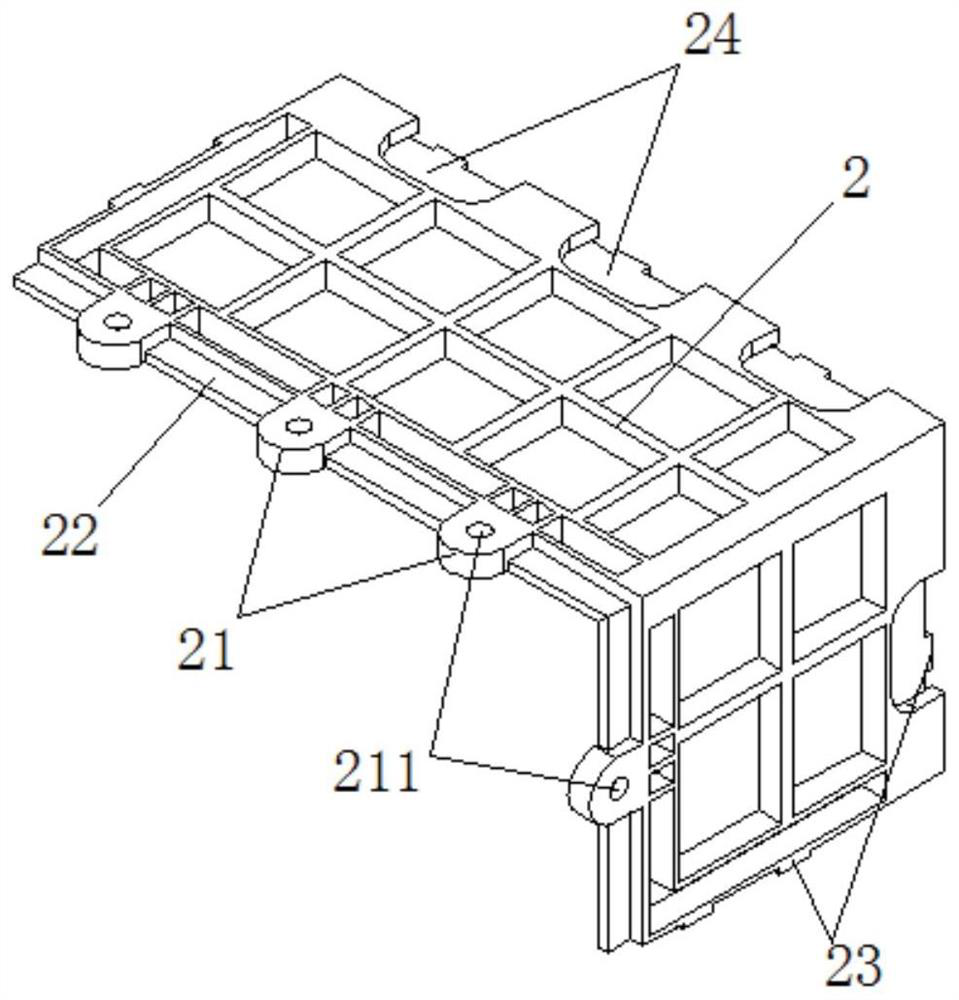

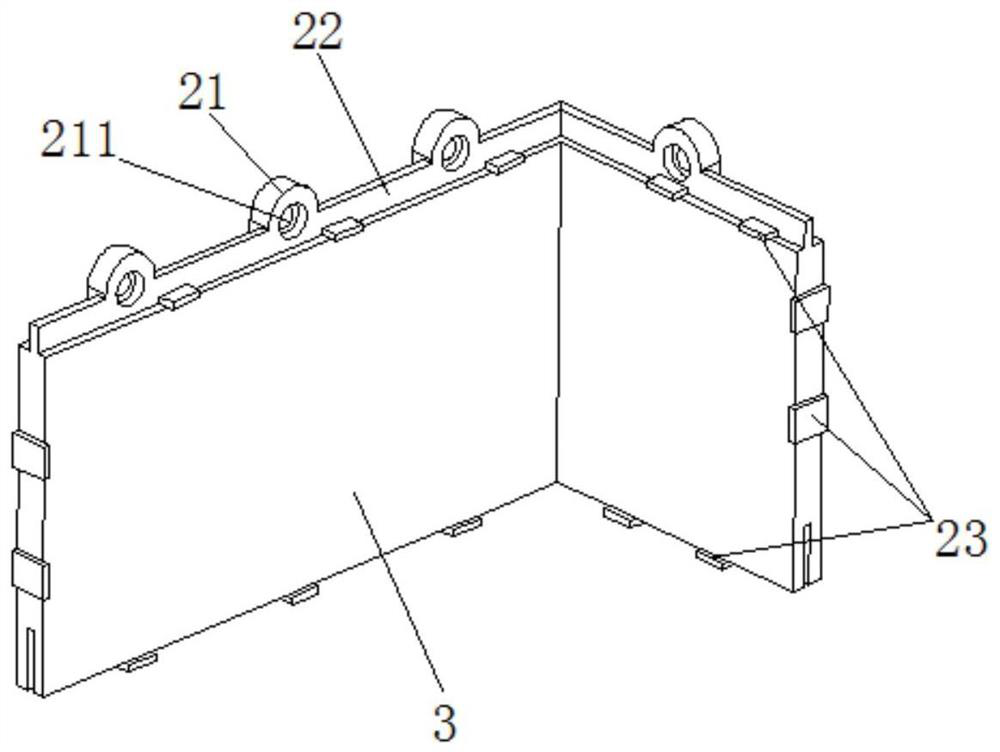

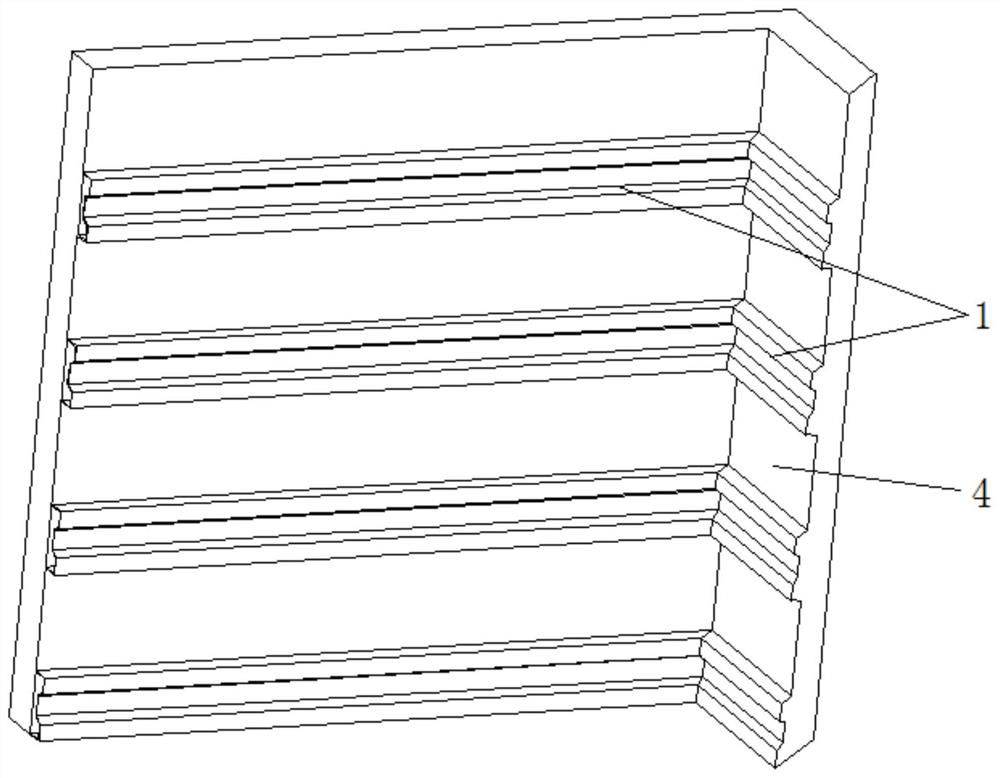

[0031] see Figure 1 to Figure 3 , the figure shows a dry-hanging structure of an assembled PP tile inner corner provided by Embodiment 1 of the present invention, including: a keel 1, which is arranged on the outer walls of both sides of the inner corner of the base wall 4; a PP chassis 2, which An articulated plate 21 is arranged on the top, and an articulated hole 211 is arranged on the articulated plate 21, and the articulated hole 211 is connected with the keel 1 through a fastener; the PP chassis 211 is in an "L" shape; the ceramic tile 3 is compositely connected to the The two inner walls of the PP chassis 2. Wherein, the PP chassis 2 is an integral structure; the fasteners are screws or screws.

[0032] The dry-hanging structure of an assembled PP tile interior corner provided in this embodiment mainly includes a keel 1, a PP chassis 2 and a ceramic tile 3, the keel 1 is arranged on both sides of the inner corner of the base wall 4, and the PP chassis 2 is "L" type, ...

Embodiment 2

[0040] see Figure 1 to Figure 2 , the figure shows a dry-hanging structure of an assembled PP tile interior corner provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: Along the length direction of the PP chassis 2, the number of the hitch plates 21 is set to be multiple, and the hitch plates 21 and the hitch holes 211 are provided in one-to-one correspondence; a connecting plate 22 is arranged between the hitch plates 21, and the connecting plates 22 The thickness is less than the thickness of the PP chassis 2. Through the setting of the above structure, the PP chassis 2 can be evenly hung on the keel 1, and the force is balanced, and the installation effect is good.

Embodiment 3

[0042] see Figure 1 to Figure 2 , the figure shows a dry-hanging structure of an assembled PP tile interior corner provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The height of the articulated plate 21 is greater than that of the connecting plate 22; the top of the articulated plate 21 is semicircular, and the articulated hole 211 is a round hole. Through the setting of the above structure, no interference phenomenon will occur when hooking, and the installation effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com