Freeze-drying method for skin-whitening, anti-wrinkle and skin-care freeze-dried powder containing collagen

A collagen and freeze-dried powder technology, applied in the field of cosmetics, can solve the problems of substandard biological activity, loose moisture control, and inactivation of collagen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

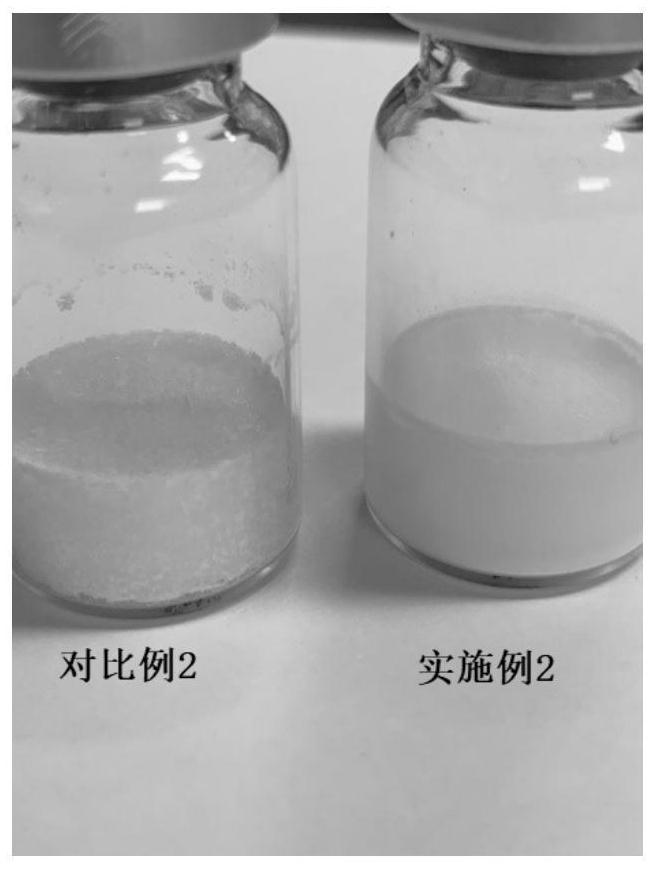

Image

Examples

Embodiment 1

[0032] (1), pre-freezing:

[0033] In the first stage, the temperature of the heat transfer oil reaches -10°C in 10 minutes and is maintained for 1 hour;

[0034] In the second stage, the temperature of the heat transfer oil reaches -45°C in 40 minutes and is maintained for 3 hours;

[0035] (2), a sublimation:

[0036] In the first stage, the temperature of the heat transfer oil reaches -30°C in 1 hour, and the vacuum degree is the ultimate vacuum, and it is kept for 10 hours;

[0037] In the second stage, the temperature of the heat transfer oil reaches -20°C in 1 hour, and the vacuum degree is 30 Pa, and it is kept for 10 hours;

[0038] In the third stage, the temperature of the heat transfer oil reaches -5°C in 1 hour, and the vacuum degree is 40 Pa, and it is kept for 10 hours;

[0039] In the fourth stage, the temperature of the heat transfer oil reaches 5°C in 1 hour, and the vacuum degree is 50 Pa, and it is kept for 3 hours;

[0040] (3), analysis drying:

[004...

Embodiment 2

[0058] (1), pre-freezing:

[0059] In the first stage, the temperature of the heat transfer oil reaches -10°C in 5 minutes and is maintained for 1 hour;

[0060] In the second stage, the temperature of the heat transfer oil reaches -45°C in 25 minutes and is maintained for 3 hours;

[0061] (2), a sublimation:

[0062] In the first stage, the temperature of the heat transfer oil reaches -30°C in 0.5 hours, and the vacuum degree is the ultimate vacuum, and it is kept for 10 hours;

[0063] In the second stage, the temperature of the heat transfer oil reaches -20°C in 0.5 hours, and the vacuum degree is 30 Pa, and it is kept for 10 hours;

[0064] In the third stage, the temperature of the heat transfer oil reaches -5°C in 0.5 hours, and the vacuum degree is 40 Pa, and it is kept for 10 hours;

[0065] In the fourth stage, the temperature of the heat transfer oil reaches 5°C in 0.5 hours, and the vacuum degree is 50 Pa, and it is kept for 3 hours;

[0066] (3), analysis dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com