Steel scrap tank weighing and metering device

A technology of measuring instruments and weighing sensors, which is applied in the direction of weighing, weighing indicating devices, and weighing auxiliary equipment, etc., and can solve problems such as the influence of weighing accuracy, the jamming of track scales, and the deformation of weighing rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

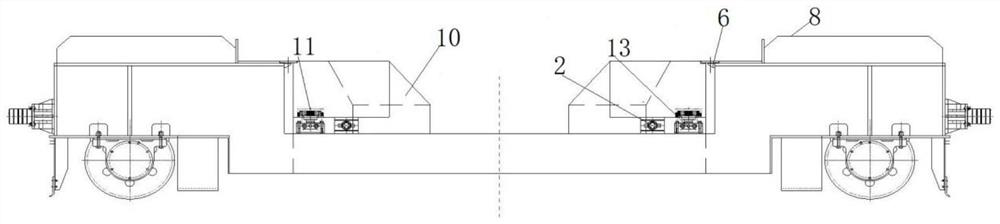

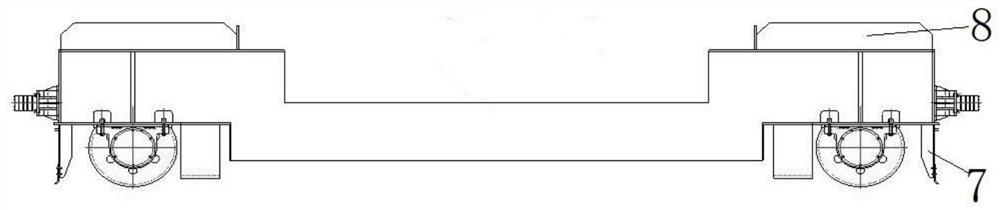

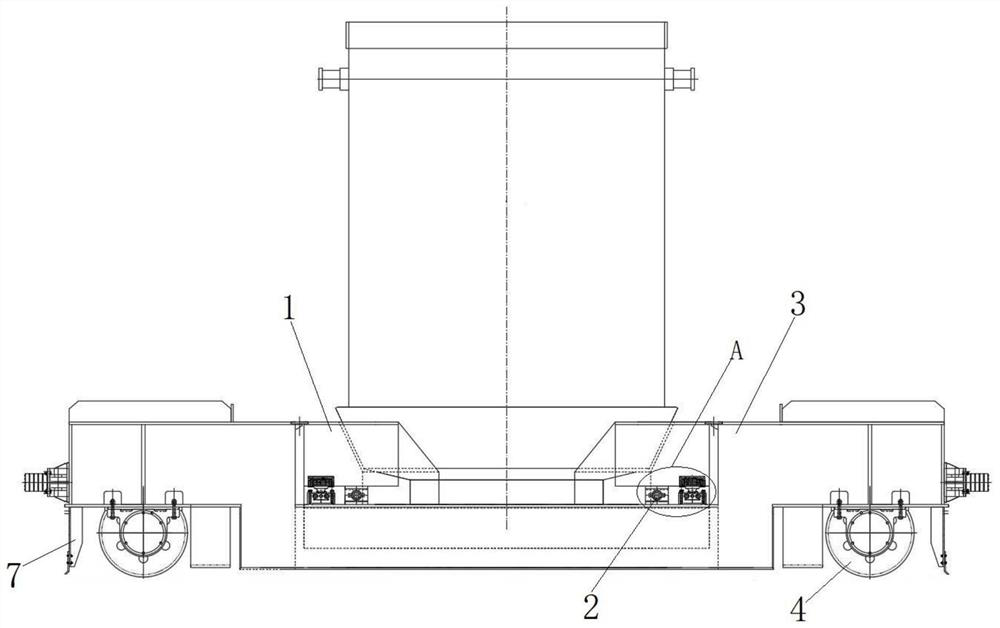

[0041] see Figure 1 to Figure 4 , the invention provides a weighing and measuring instrument for scrap steel tanks, comprising a car body 3, a weighing sensor 13, and a weighing carrier 1; the car body 1 is provided with a weighing tank; the weighing sensor 13 is arranged in the weighing tank , and connected with the weighing digital transmission machine through the signal line, the weighing digital transmission machine uses wireless data transmission to transmit the weighing signal to the weighing display in the central control room, and the weighing digital transmission machine is fixedly installed on the car body 3 The weighing carrier 1 is arranged in the weighing tank, and is connected with the load cell 13 by the sensor pressure head...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap