Complex Steel Concrete Composite Structure and Construction Method

A combination structure and construction method technology, applied in the direction of building types, building components, building structures, etc., can solve the problem that the construction technology of steel-concrete composite structures cannot meet the requirements, the construction efficiency of steel-concrete composite structures is low, and the positioning accuracy of steel columns is poor. problems, to achieve the effect of preventing concrete voids, speeding up construction efficiency, and enhancing connection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The invention provides a construction method of a complex steel-concrete composite structure, the construction method comprising the following steps,

[0038] Step 1. Construction of steel concrete slab-column joints using complex steel-concrete column-slab structures:

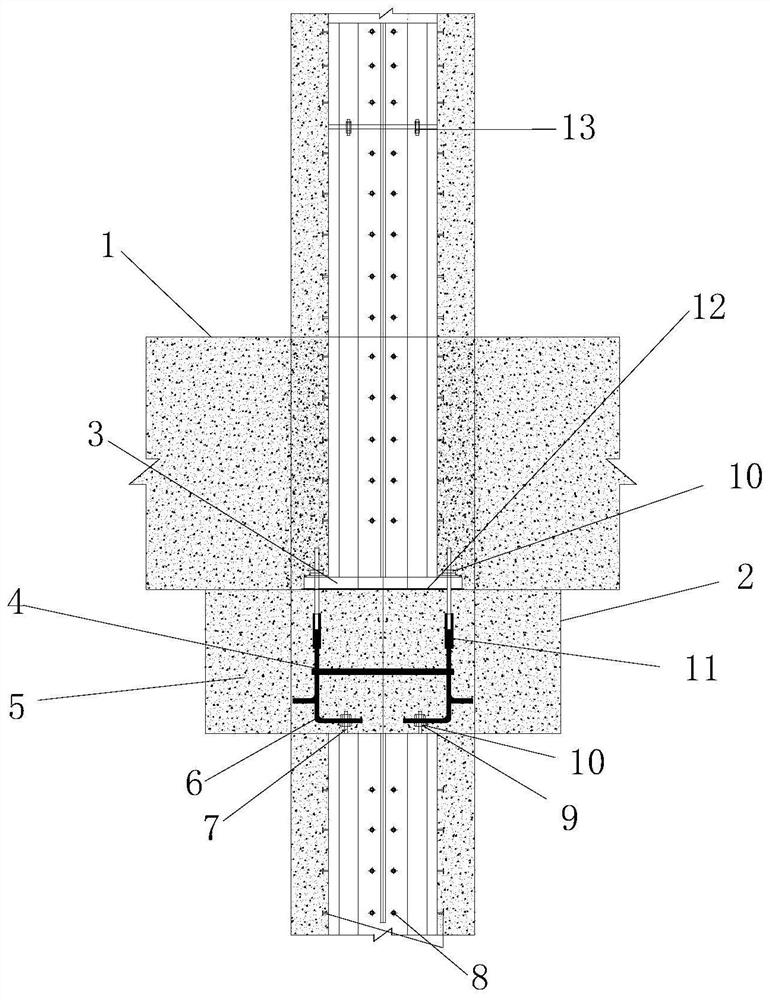

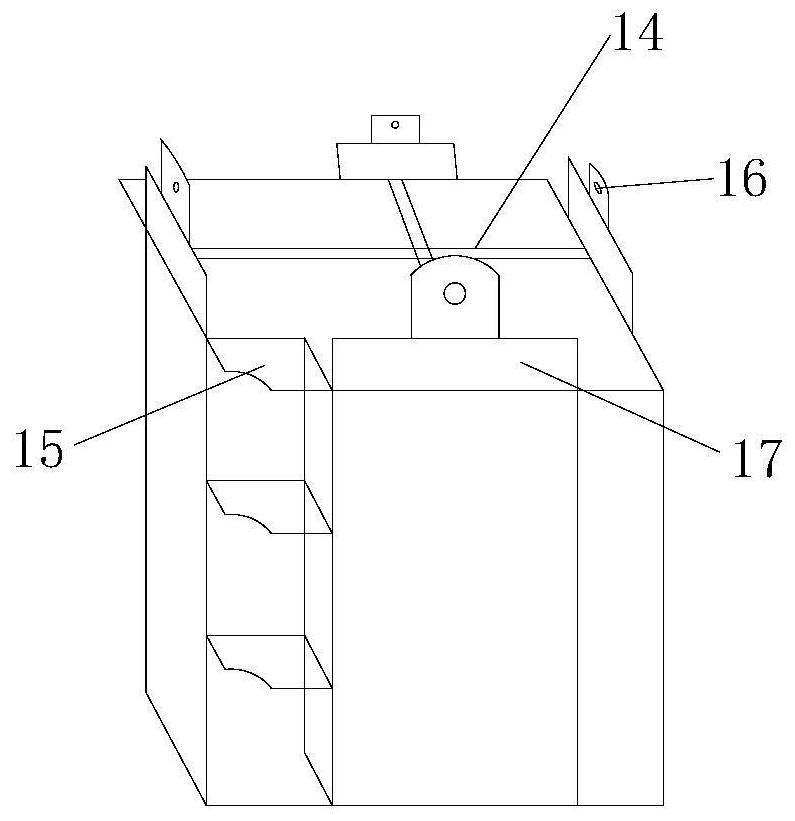

[0039] The complex steel concrete column-slab structure mainly includes a floor slab 1, a steel column bottom plate 3, positioning stirrups 4, concrete 5, special-shaped connecting members 6 and a steel column; The edge 17 and the lug plate 7 are welded in the factory, the steel flange 17 is set around the steel web 14, the stiffening rib 15 is set on the side of the steel flange 17, the lug plate 7 is set on the upper part of the steel flange 17, and the lug plate 7. Set the lug hole 16; the steel column connection at the joint 40 of the steel concrete slab column connects the lug plate 7 and the bottom plate of the steel column 3 through a special-shaped connecting member 6, and the special-shaped conne...

Embodiment 2

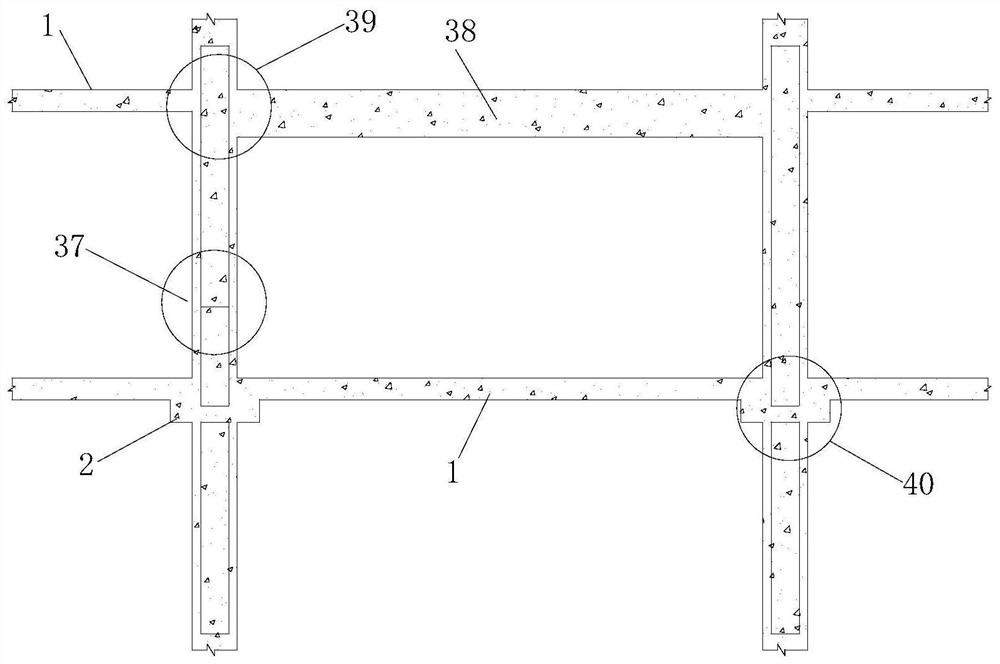

[0050] The complex steel-concrete composite structure is constructed through the structures mentioned above at the steel-column splicing joints, steel-concrete beam-column joints, and steel-concrete slab-column joints, so that the poured complex steel-concrete composite structure has seismic performance, high efficiency, convenience, It has the characteristics of low safety hazard and wide application range.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap