Soil sample preparation method and device

A preparation device and soil technology, applied in the field of soil sample preparation, can solve the problems of sample cross-contamination, waste of electrical resources, low preparation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

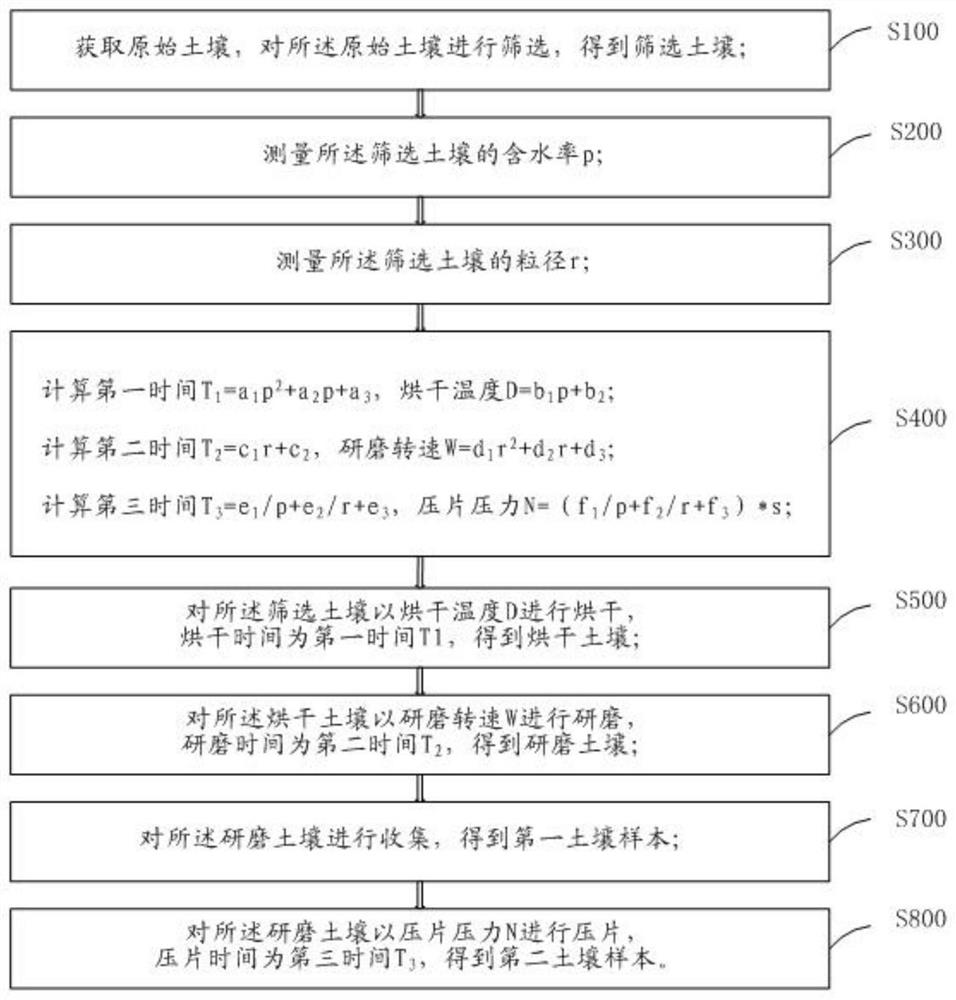

[0046] Please refer to figure 1 A flow chart of a soil sample preparation method provided for this application, including the following steps:

[0047] obtaining original soil, and performing primary screening on the original soil to obtain primary screening soil;

[0048] Measure the moisture content p of the first sieve soil;

[0049] Measuring the particle size r of the primary sieve soil;

[0050] Calculate the first time T 1 =a 1 p 2 +a 2 p+a 3 , drying temperature D=b 1 p+b 2 ; Calculate the second time T 2 = c 1 r+c 2 , Grinding speed W=d 1 r 2 +d 2 r+d 3 ;Calculate the third time T3=e 1 / p+e 2 / r+e 3 , Tablet pressure N=(f 1 / p+f 2 / r+f 3 )*s, s is the tablet area;

[0051] The first sieved soil is dried at the drying temperature D, and the drying time is the first time T 1 , to get dry soil;

[0052] The dried soil is ground at the grinding speed W, and the grinding time is the second time T 2 , to get ground soil;

[0053] collecting the gro...

Embodiment 2

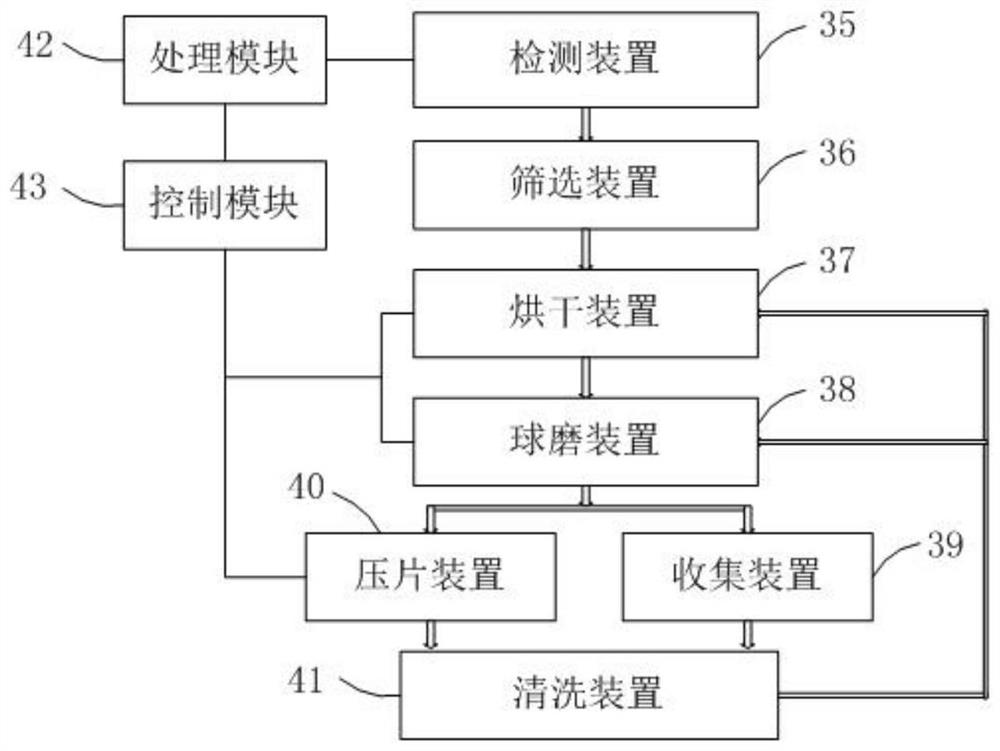

[0069] Please refer to figure 2 A schematic diagram of a soil sample preparation device provided in this application, including a detection device 35, a drying device 37, a ball milling device 38, a tableting device 40, a control module 43 and a processing module 42;

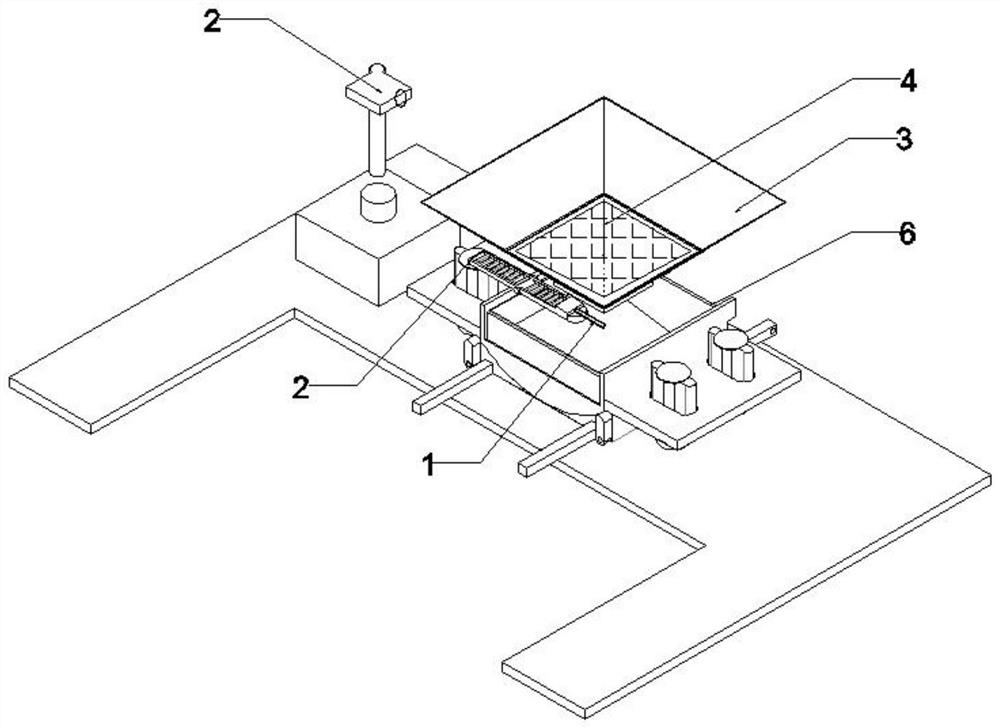

[0070] The detection device 35 includes: a humidity sensor 1, a camera 2; the humidity sensor 1 is connected to the input terminal of the control module 43 for detecting the water content p of the soil; the camera 2 is connected to the input of the processing module 42 Terminal connection is used for taking soil image; The output terminal of described processing module 42 is connected with the input terminal of described control module 43;

[0071] The drying device 37 is connected with the output end of the control module 43 for drying the soil; the ball milling device 38 is connected with the output end of the control module 43 for grinding the soil; The device 40 is connected to the output end of the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com