Sample splitter for sorting soil samples

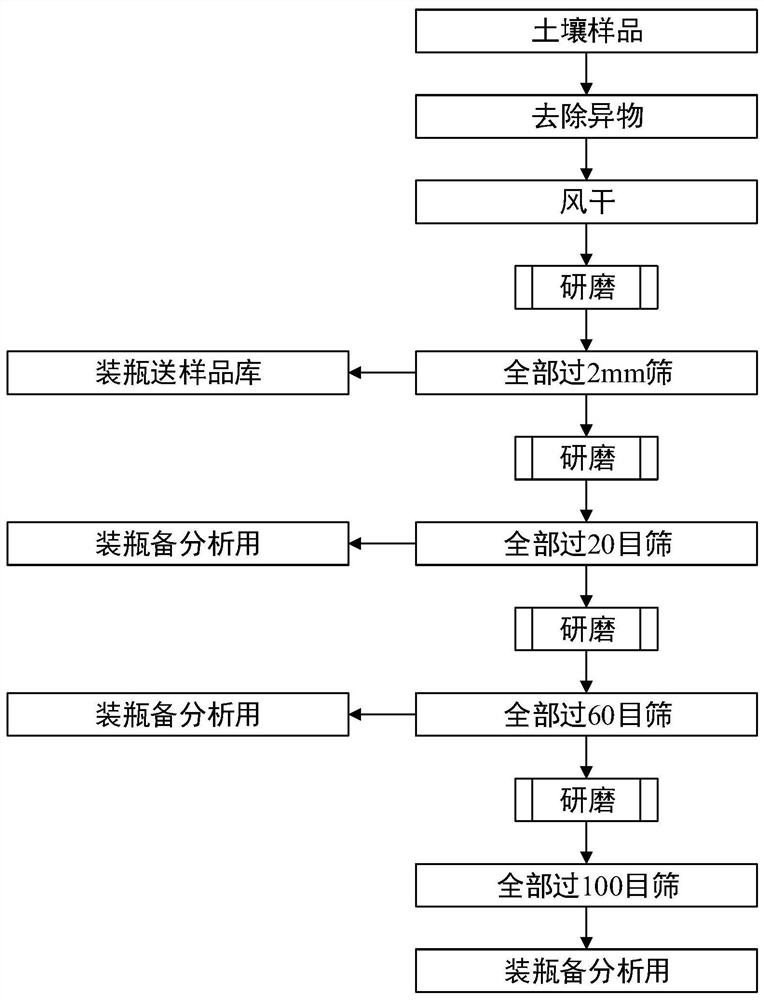

A soil sample and sample divider technology, which is applied in the preparation of test samples, etc., can solve the problems of long cycle time, high personnel quality requirements, heavy workload, etc., and achieve uniform properties, increase preparation phase rate, and uniform separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

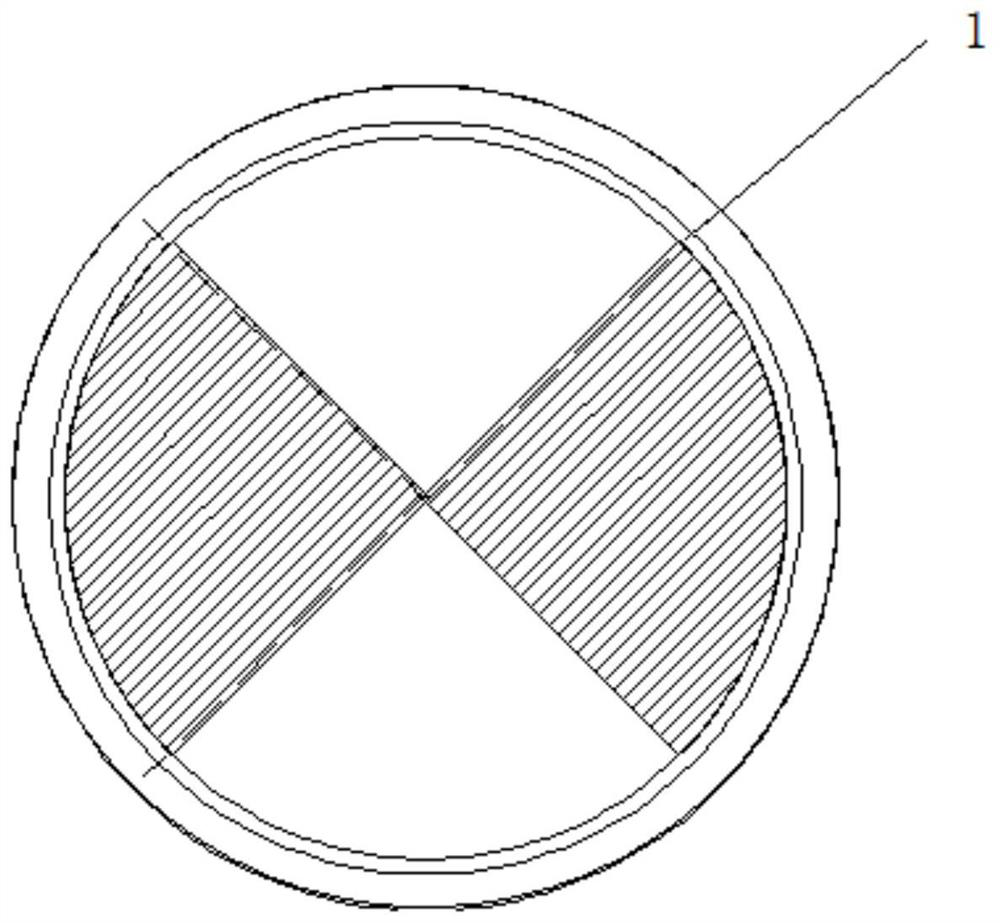

[0018] Embodiment 1: see attached figure 2 , a sample divider for sorting soil samples, the main body of the sample divider 1 is a circular frame-shaped or square frame-shaped structure, and its interior is divided into four or greater than four even-numbered symmetrical area, in which half of the bottom surfaces are closed, and the areas with closed bottom surfaces are arranged at intervals. In this example, in order to realize the quartering of the soil sample, the inside of the sampling device 1 is divided into four symmetrical intervals.

[0019] When the soil samples are normally distributed and fall naturally along the centerline of the sampling device 1, half of the soil samples fall through the unclosed area, and the other half of the soil samples are evenly retained in the closed area at the bottom, so as to realize the sampling of the soil samples. Evenly separated.

Embodiment 2

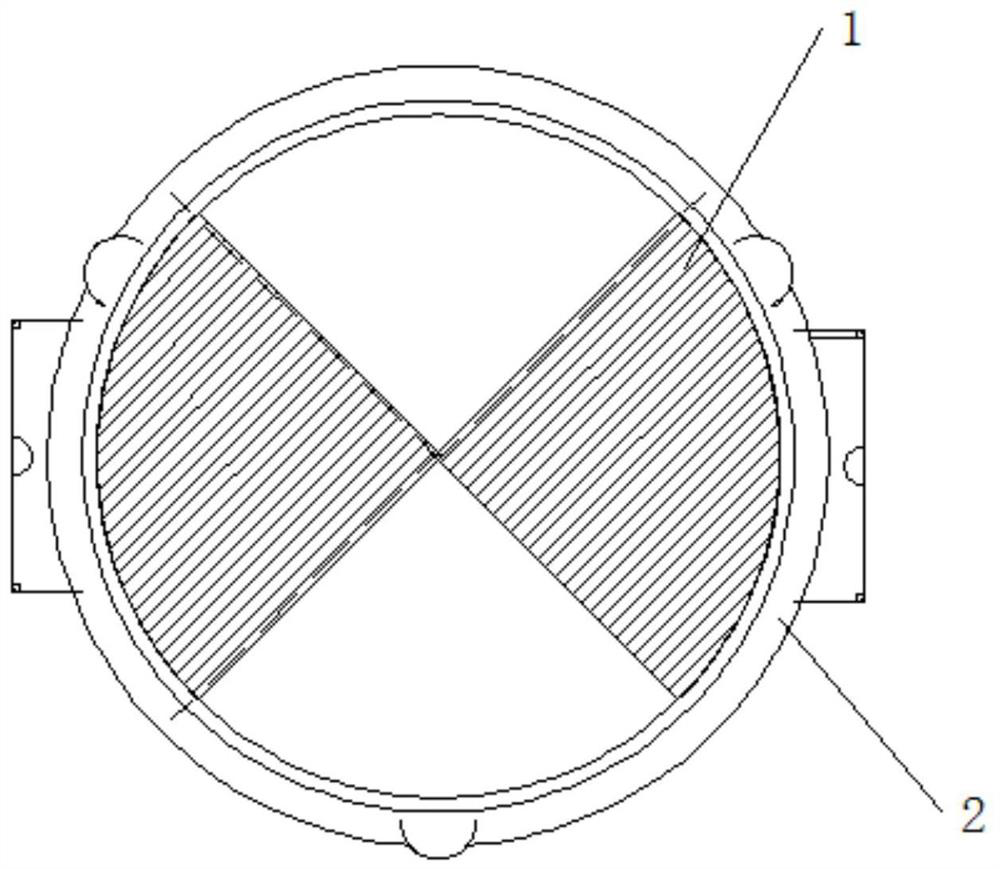

[0020] Embodiment 2: see attached image 3 , On the basis of Embodiment 1, the sample dividing device 1 is directly arranged in the vibrating screen 2, so that the function of sieving and dividing samples of the vibrating screen 2 can be realized.

[0021] See attached Figure 4 Further, the structure of the vibrating screen 2 includes: an outer frame 21 and a filter screen 22 embedded in the outer frame 21; in order to increase the sample screening efficiency, the cross section of the filter screen 22 can be an inverted cone structure, and the filter screen 22 Grinding balls 23 are arranged in the annular surface between the outer frame 21; when vibrating, the grinding balls 23 are subjected to secondary vibration by the elastic force of the filter screen 22, and bounce against the filter screen 22 when falling and rebounding to strengthen the vibration effect.

Embodiment 3

[0022] Embodiment 3: see attached Figure 5 , On the basis of Example 1, the sample dividing device 1 is arranged at the inlet of the funnel 3, and the outlet of the funnel 3 is opposite to the sample loading container, so that the functions of sample dividing and packaging can be realized simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com