Transformer tap switch based on brake cable control

A tap changer and brake line technology, applied in transformers, variable transformers, electric switches, etc., can solve the problems of transmission delay, high production cost, and low transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

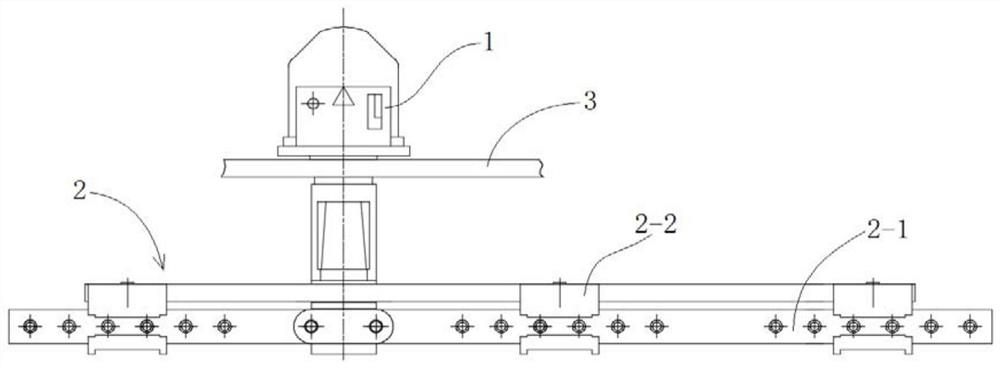

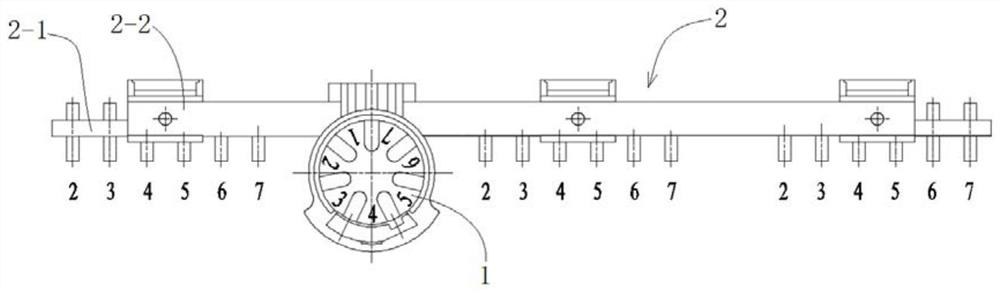

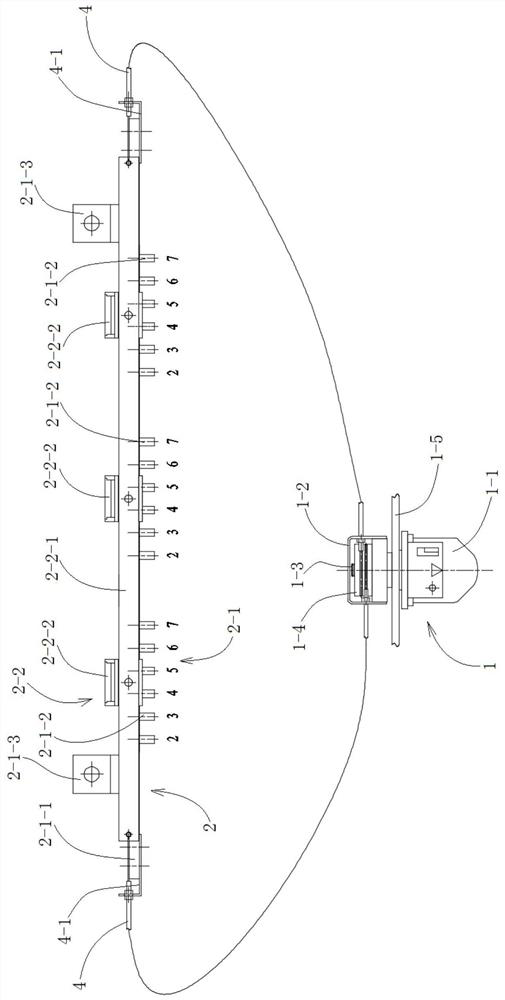

[0043] Take the transformer bar tap changer as an example. see image 3 and Figure 4 As shown, a transformer tap changer based on brake line control in this embodiment includes a remote operating mechanism 1 and a tap changer main body 2. The tap changer main body 2 includes a static contact assembly 2-1 and the above static contact assembly 2-1. The moving contact assembly 2-2 of the contact assembly 2-1 is relatively slidable and switched, which is similar to the structure of the existing tap changer. The static contact assembly 2-1 is mainly composed of the static contact bracket 2-1-1 and installed on the static Several groups of static contacts 2-1-2 are formed on the contact bracket 2-1-1, and the moving contact assembly 2-2 is mainly composed of the moving contact bracket 2-2-1 and the moving contact bracket 2-2 -1 consists of several groups of moving contacts 2-2-2, the moving contacts 2-2-2 cooperate with the static contacts 2-1-2, the static contact assembly 2-1 a...

Embodiment 2

[0048] A transformer tap-changer based on brake line control in this embodiment has the same basic structure and working principle as that of Embodiment 1, the difference is that the main body 2 of the tap-changer is also provided with a drive contact assembly 2 -2 Slide and switch the proximal control mechanism 5 that fits on the static contact assembly 2-1. Specific as Figure 5 and Figure 6As shown, a transformer tap changer based on brake line control in this embodiment includes a remote operating mechanism 1 and a tap changer main body 2. The tap changer main body 2 includes a static contact assembly 2-1 and the above static contact assembly 2-1. The contact assembly 2-1 is relatively sliding to switch the matched moving contact assembly 2-2. It should be understood that the above-mentioned "relative sliding switching" is a relative linear sliding switching for the bar tap changer, and for the cage tap changer and For the disc tap changer, it is relatively rotating and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com