Mechanical self-hold electromagnetic relay

An electromagnetic relay and self-holding technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems affecting the reliability of relays, consume energy, increase switching costs, etc., so as to reduce labor costs and save power consumption. , the effect of reducing thermal requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

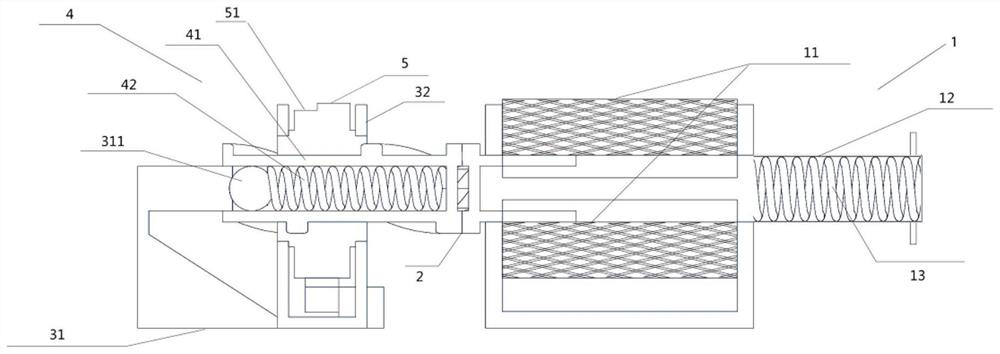

[0061] The embodiment of the present invention discloses a mechanical self-holding electromagnetic relay, such as Figure 1-3 As shown, it includes: an electromagnetic linear driver 1 with a reset function, a push head 2, a bracket 3, a drive rod 4 with a reset function, and a one-way rotating wheel 5 (the wheel 5 is provided with a ratchet and positioning ratchet), a touch switch 6 that realizes conduction through touch pressure; the electromagnetic linear drive member 1 is connected with the push head 2 to drive the push head 2 in a linear direction; one end of the push head 2 One end of the drive rod 4 is a helical tooth that cooperates with each other, and the two cooperate with each other to make the push head 2 mesh with one end of the drive rod 4 to form a one-way clutch; the other end of the drive rod 4 One end is provided with reset device 42, and described reset device 42 is connected with described bracket 3; When the push head 2 is driven, the runner 5 is driven t...

Embodiment 2

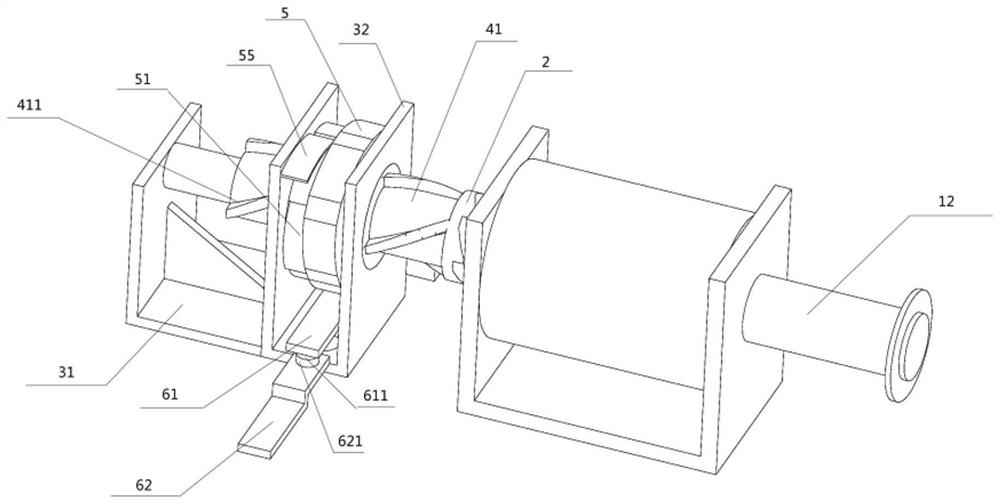

[0085] Embodiment 2 of the present invention also discloses a mechanical self-holding electromagnetic relay, such as Figure 4 As shown, the difference from Embodiment 1 is that the runner 5 and the drive rod 4, specifically, the runner 5 in Embodiment 2 is provided with a ratchet 51 and a cross 56 (the four tops of the cross 56 are convex parts 53, The remaining part is the concave portion 54, and the composition structure on the runner 5 is not limited to the cross 56, as long as there is a convex portion 53 and a concave portion 54, and the structure of the convex portion 53 and the concave portion 54 can be switched periodically), the positioning The fixed end of the ratchet 55 is connected to the bracket 3; the positioning ratchet 55 is close to the ratchet 51; the ratchet 51 is fixedly connected to the cross 56 and the central axis of the two coincides; the drive rod 4 is set There is a propelling pawl 14 close to the ratchet wheel 51 , and the runner 5 is pushed by the ...

Embodiment 3

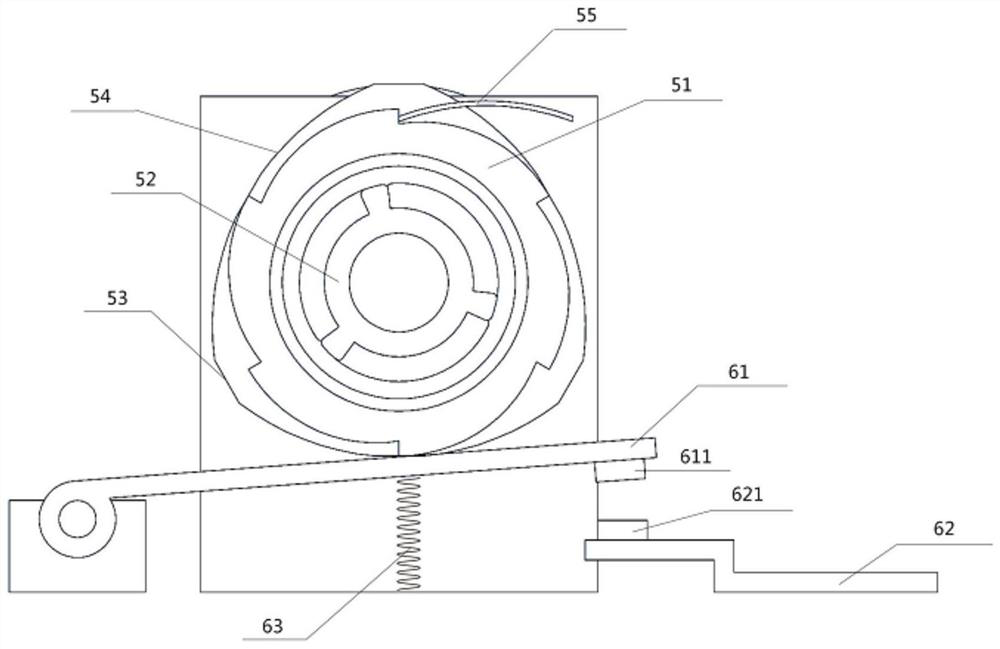

[0091] Embodiment 3 of the present invention also discloses a mechanical self-holding electromagnetic relay, such as Figure 5 As shown, the difference from Embodiments 1 and 2 is that the runner 5 and the touch switch 6, the movable end of the cross 56 is provided with a movable contact 611 (the specific movable contact piece 61 is directly cross-shaped); The touch switch 6 includes: a moving contact piece 61, a static contact piece 62, and a spring 63; wherein,

[0092] The cross 56 is the movable contact piece 61; the top of the cross 56 as the movable end is provided with a movable contact 611;

[0093] The static contact piece 62 is connected to the spring 63, so that the movable contact 611 does not contact the static contact 621 on the static contact piece 62 under the condition of not being pressed.

[0094] Thus, the cross-shaped movable contact piece 61 is embedded on the disc integrated with the ratchet 51 . The ratchet 51 rotates one tooth, the cross-shaped movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com