Planographic printing original plate, and method for manufacturing planographic printing original plate

A technology for lithographic printing plates and original plates, which is applied in the field of manufacturing original lithographic printing plates and original plates of lithographic printing plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0388] Hereinafter, although an Example demonstrates embodiment of this invention in detail, this invention is not limited to these.

[0389] First of all, the methods for producing the support, the method for forming the undercoat layer, the method for forming the image recording layer, the method for forming the protective layer, the method for forming the resin layer (back coat layer), the method for forming the resin layer (back coat layer), and The coating method of an ink repellent agent is demonstrated.

[0390]

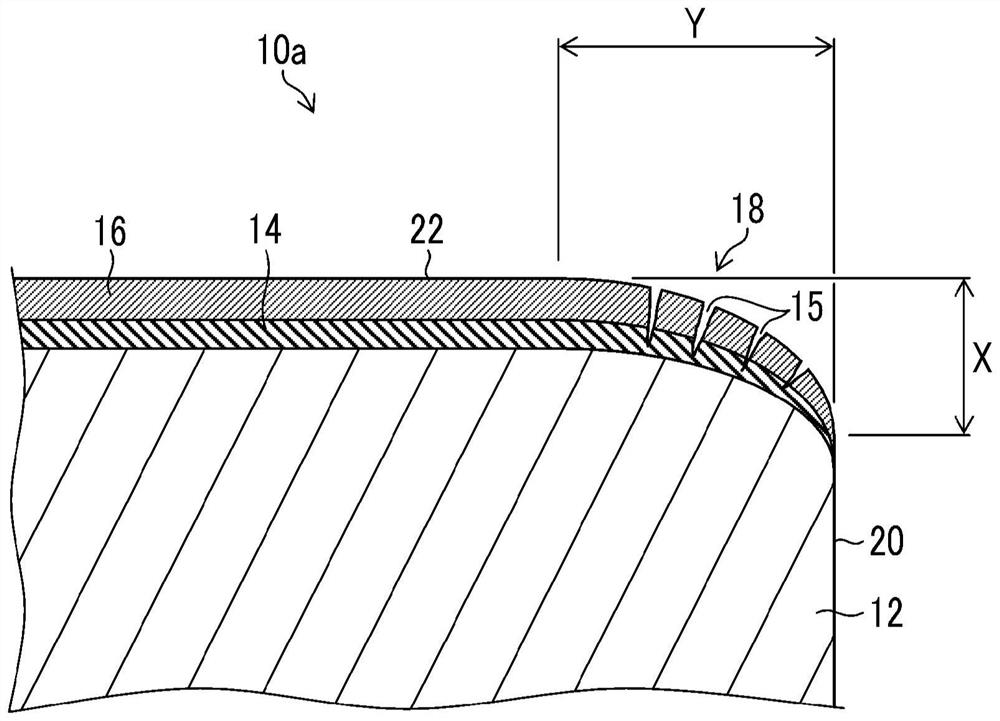

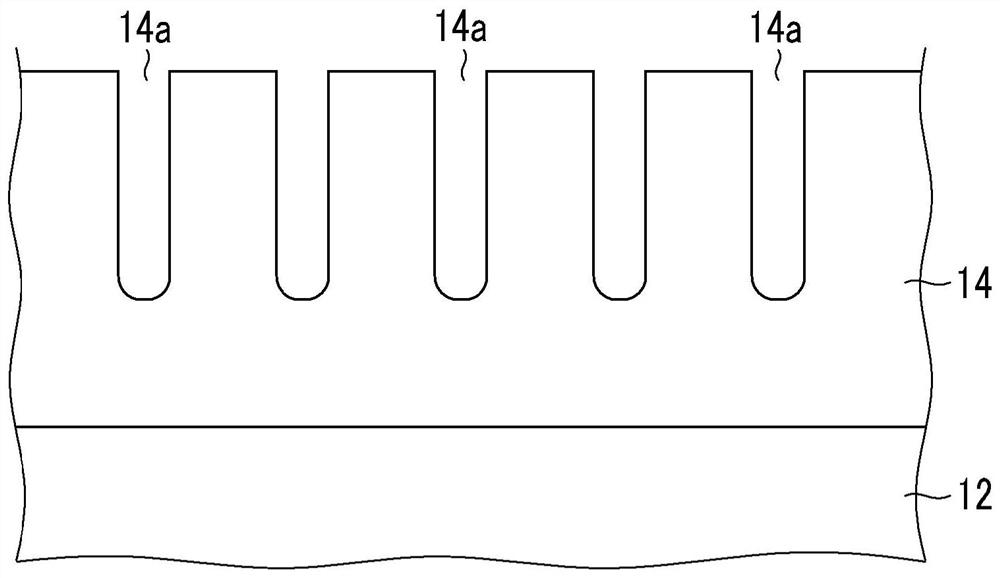

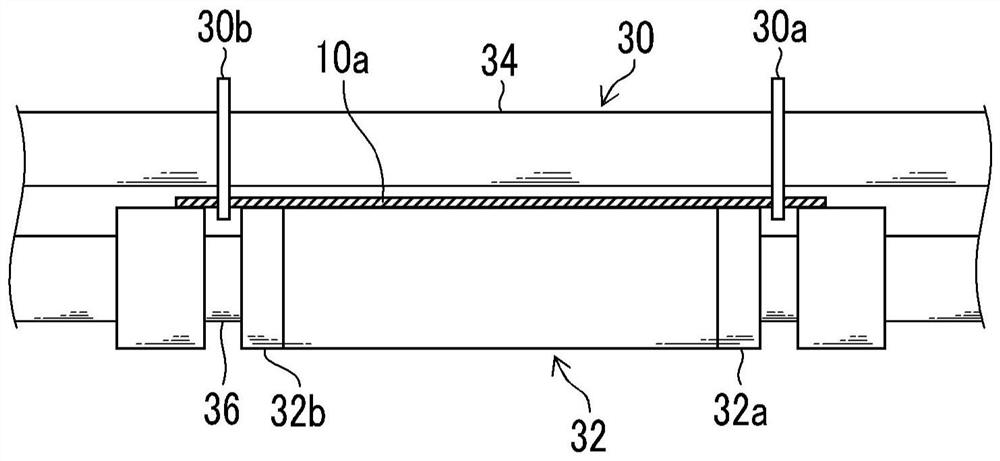

[0391] Each of the following treatments (a) to (f) was sequentially performed on the aluminum plate to prepare an aluminum support having an anodized film (support (1)). In addition, water washing treatment was implemented between all the treatment steps.

[0392] (a) Alkali etching treatment

[0393] An aqueous solution having a sodium hydroxide concentration of 25% by mass, an aluminum ion concentration of 100 g / L, and a temperature of 60° C. was sprayed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com