Method and apparatus for removing mucous membrane from wafer

A wafer and mucous membrane technology, applied in the field of semiconductor wafers, can solve the problems of wafer edge contamination, narrow application range, easy contamination, etc., and achieve the effects of preventing edge contamination, wide application range and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

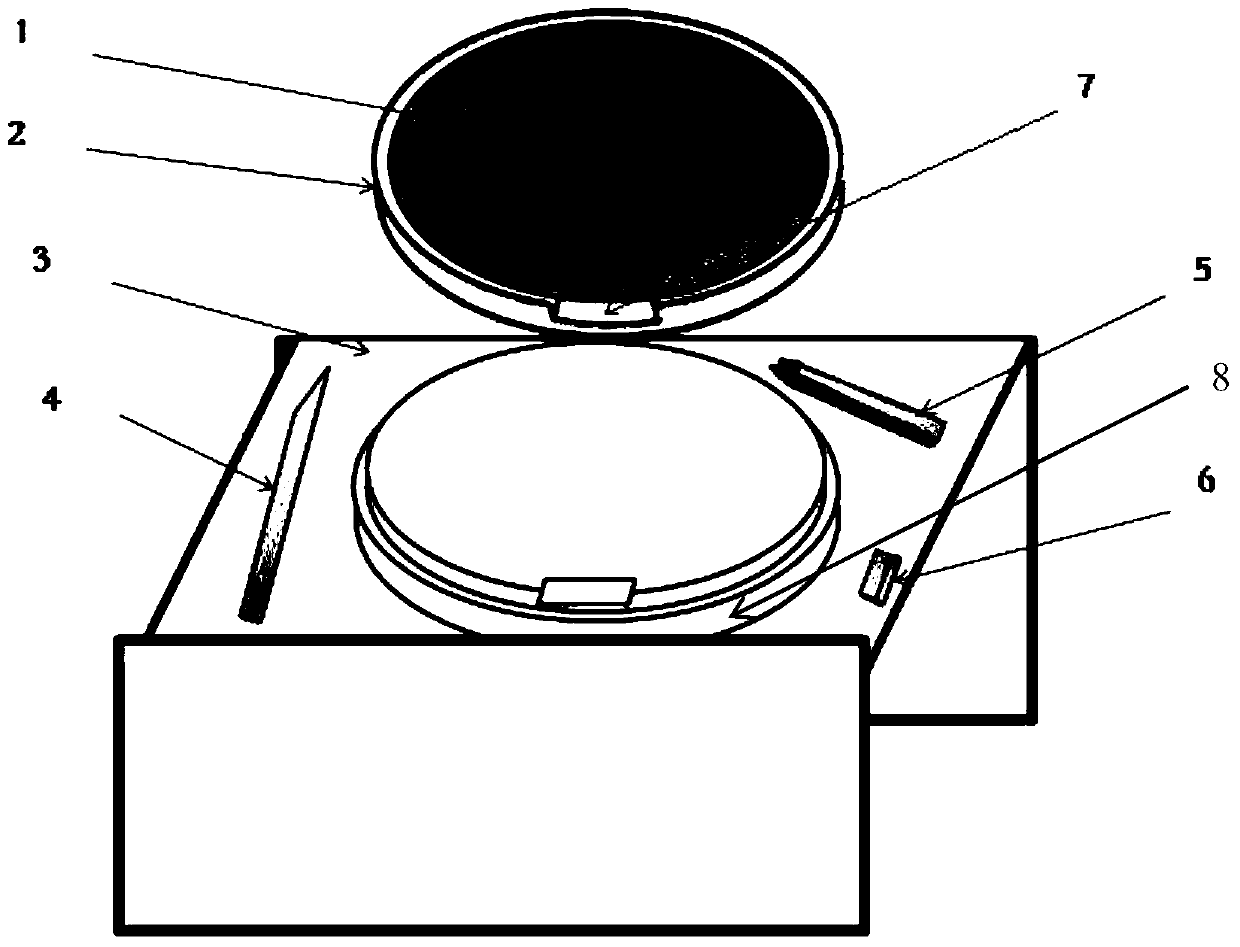

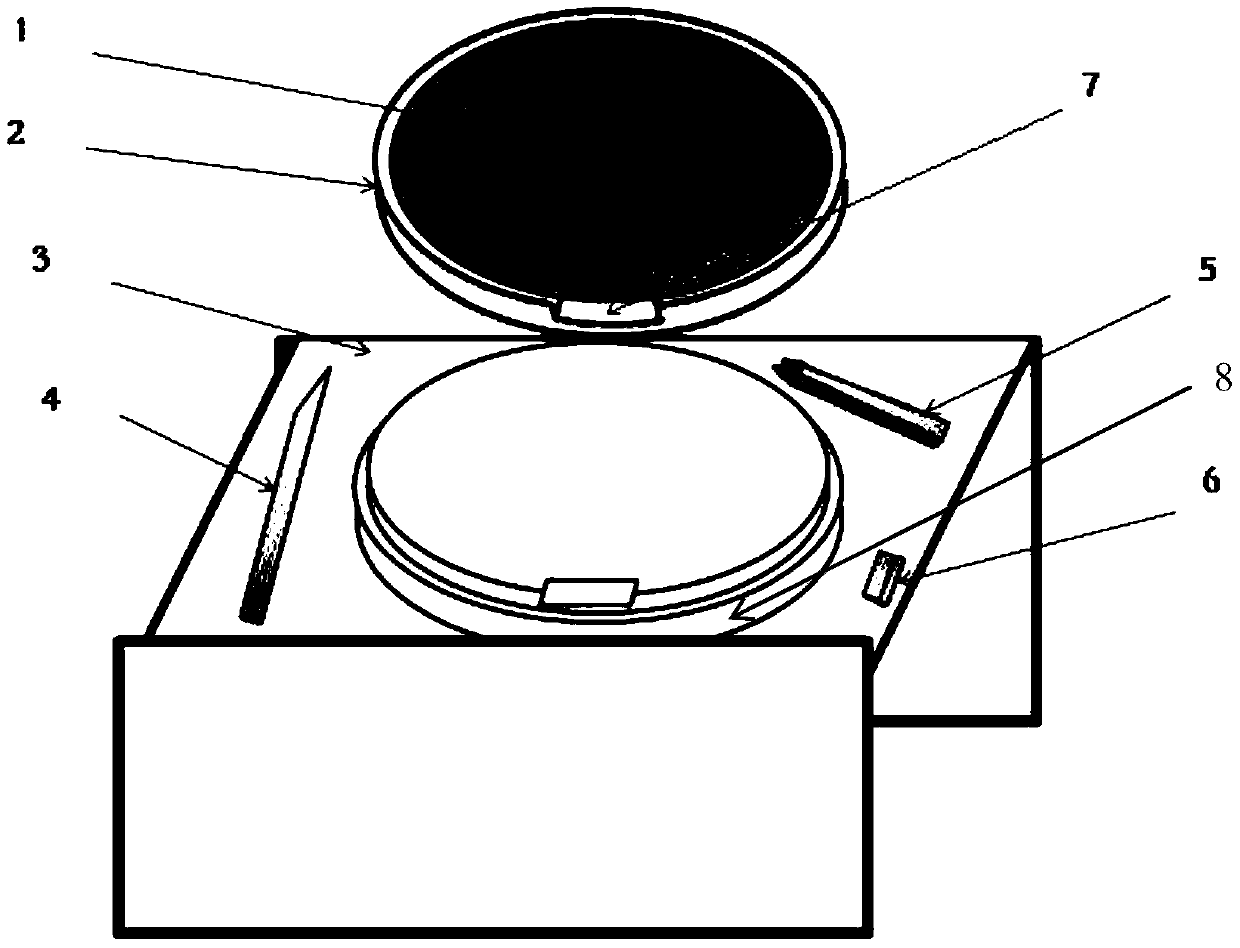

Image

Examples

Embodiment Construction

[0018] It should be understood that the following embodiments are only exemplary and do not limit the present invention. The protection scope of the present invention is defined by the claims. It should also be understood that in implementing the present invention, not all technical features in the following embodiments may be included, and there may be various combinations of these technical features.

[0019] In the present invention, unless otherwise stated, all operations are carried out at room temperature and normal pressure.

[0020] In the present invention, the surface of the wafer refers to the two surfaces with the largest area, and the dimension between the two surfaces is the thickness; the edge of the wafer refers to the outer edge of the two surfaces. When referring to "putting the wafer on a wafer support table in an inclined state", it means that the tangential direction of the wafer surface (ie, the direction perpendicular to the thickness of the wafer) is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com