Poultry egg conversion machine

A technology for converting machines and eggs, applied in the field of egg converting machines, can solve the problems of fragile eggs and large footprint, and achieve the effect of reducing occupied space and improving space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

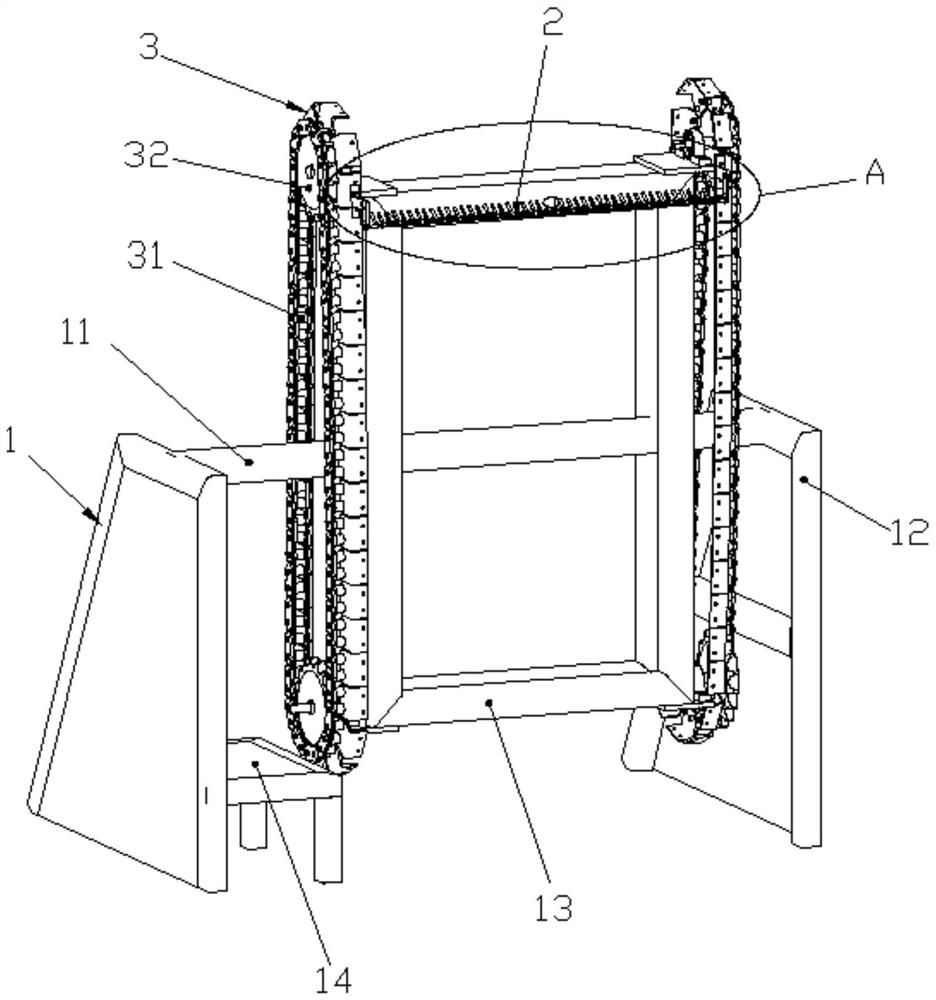

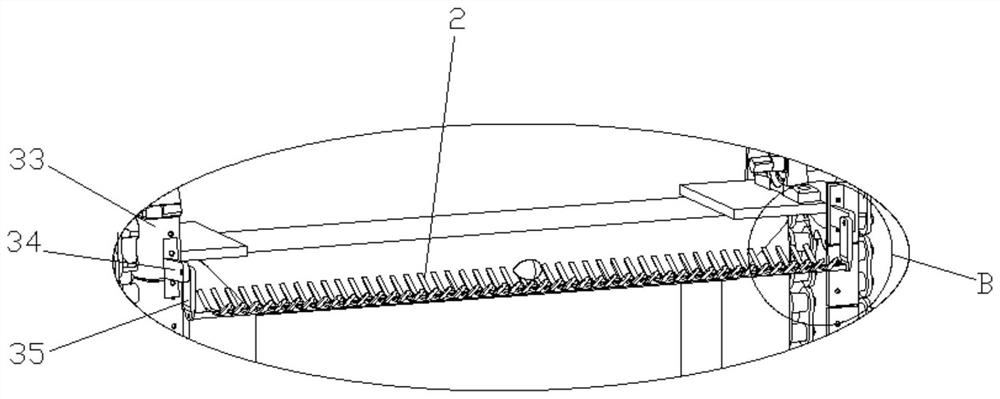

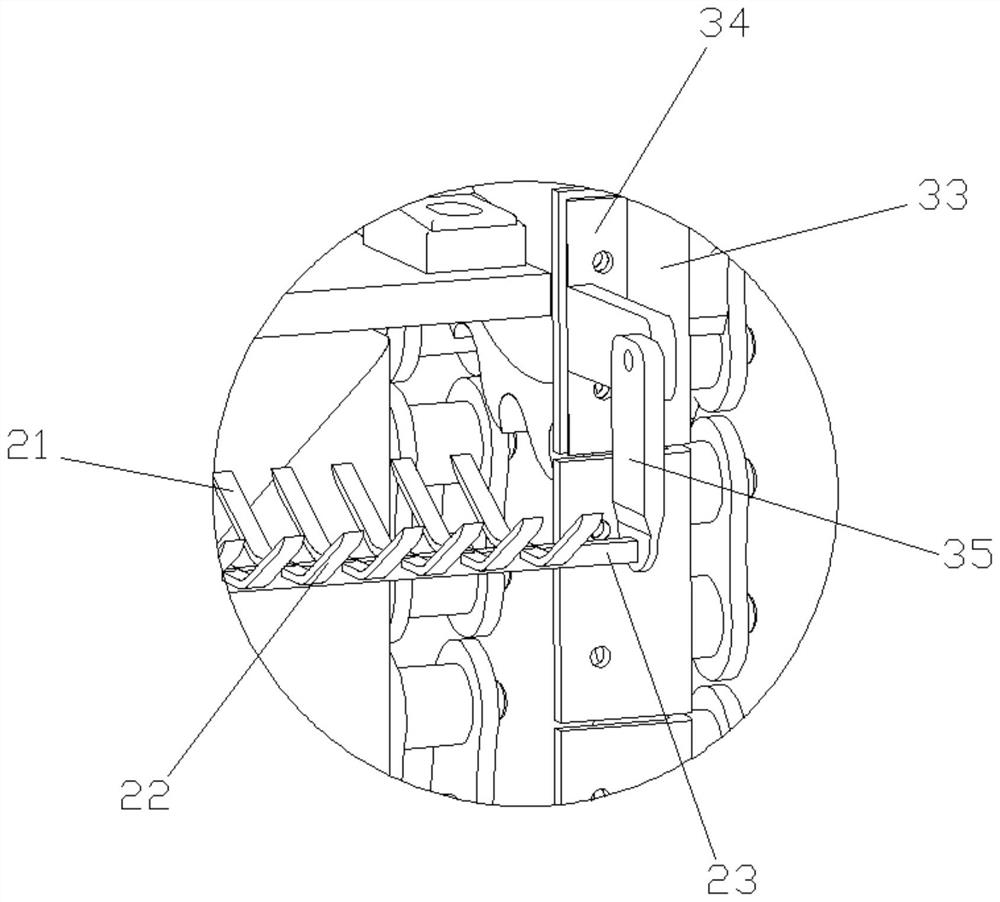

[0022] Embodiment: a kind of poultry egg conversion machine, as Figure 1-4 As shown, it includes a frame 1, multiple sets of conversion slots 2, and a transmission mechanism that drives the transfer slots 2 to move up and down in a cycle, wherein the frame 1 includes a beam 11 and side supports 12 arranged at both ends of the beam 11 for supporting the beam, A square frame 13 is fixed on the beam 11 , and the transmission mechanism is arranged on the square frame 13 .

[0023] In this embodiment, the transmission mechanism adopts the mode of chain transmission, including two chain transmission groups 3, each chain transmission group 3 includes a chain 31 and two sprockets 32 that drive the chain 31 to rotate, and the chain 31 is sleeved on the sprocket 32 and meshed with the sprocket 32, the transmission direction of the chain 31 is the vertical direction. A total of four sprockets 32 are respectively arranged at the four corners of the square frame 13 through bearings, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com