Pressure-resistant greening brick and preparation method thereof

A brick body and molding technology, which is applied in the field of pressure-resistant greening bricks and its preparation, can solve the problems of low water permeability, air permeability and compression resistance of greening bricks, reduce dust, purify air, and improve urban ecology environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

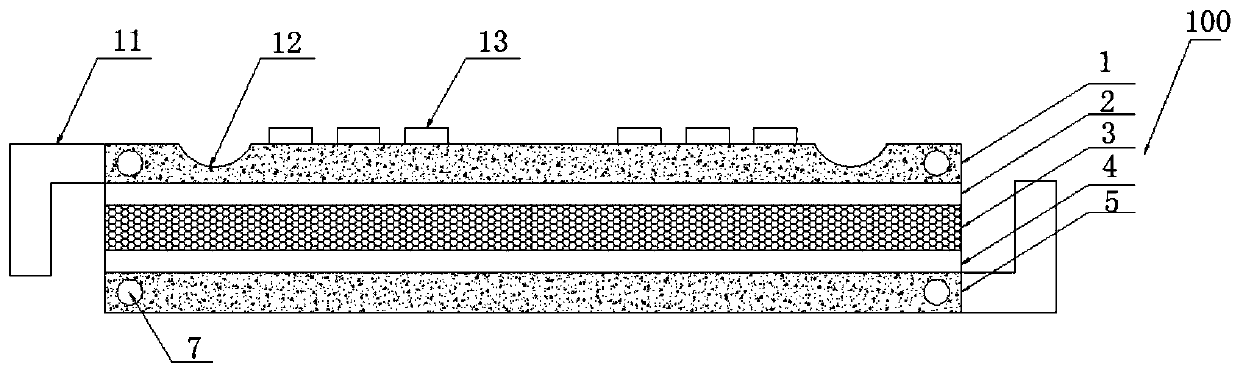

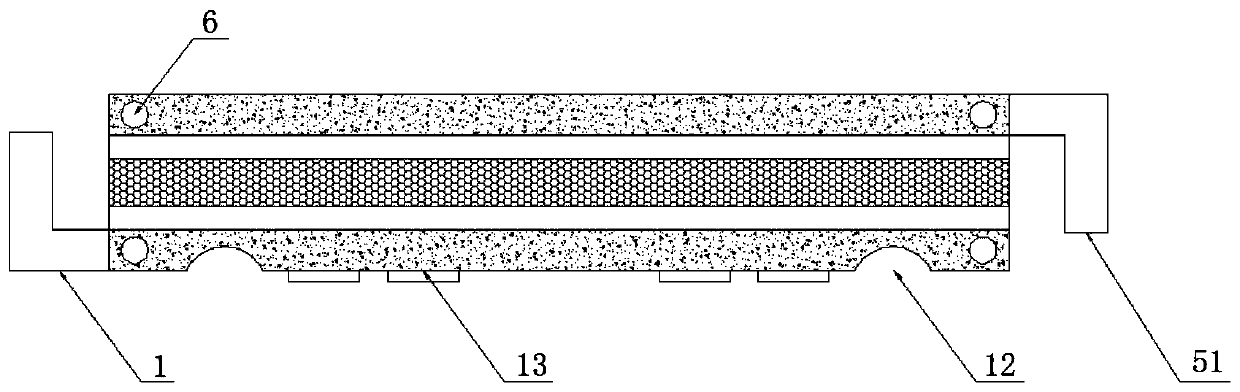

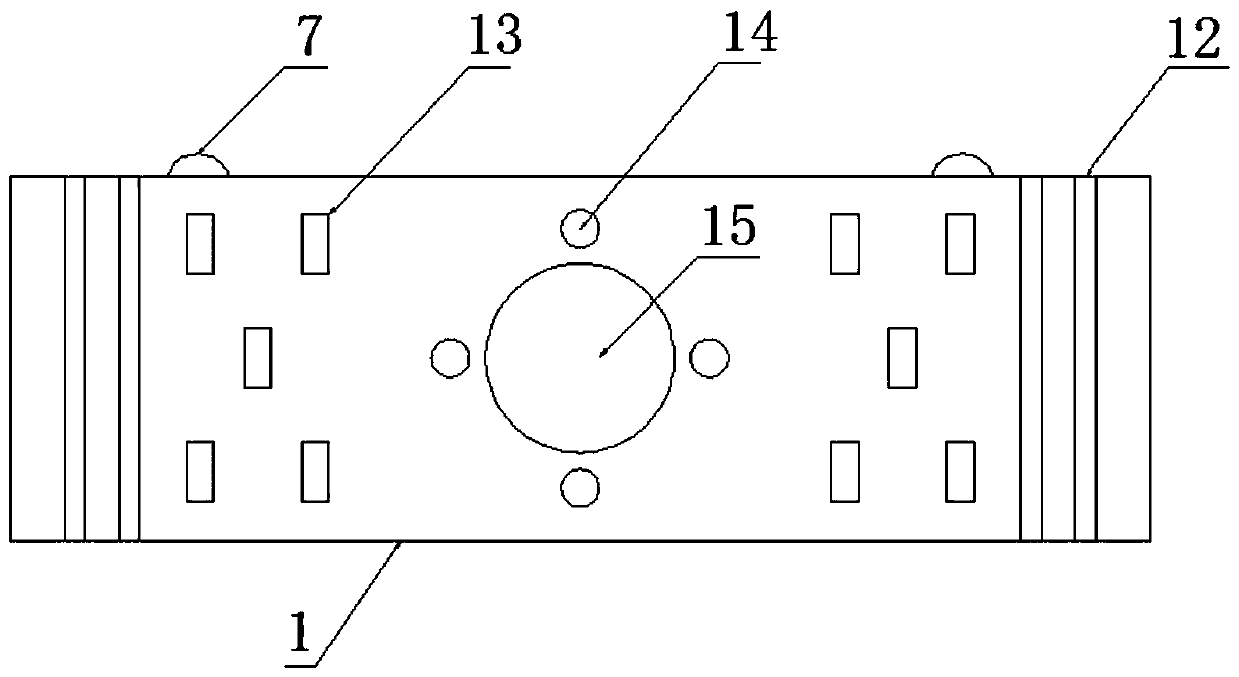

[0023] Please refer to Figure 1-4 As shown, a brick for anti-compression greening includes a brick body 100, and the brick body 100 is sequentially composed of an upper brick body 1, an upper adhesive layer 2, a high-strength rubber layer 3, a lower adhesive layer 4 and a lower brick body from top to bottom. Body 5 is compounded, and brick body 100 is a rectangular body; planting holes 15 are engraved at the intersection of diagonal lines of upper brick body 1, and a number of water permeable holes 14 are distributed in a circular equidistant manner outside planting hole 15, and both sides of the upper surface of upper brick body 1 are engraved The first drainage g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com