Auxiliary installation equipment for internal combustion engine bottom cover

A technology for installing equipment and internal combustion engines, which is applied in the direction of workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of inability to meet the needs of assembly line installation, lack of auxiliary installation equipment, and inconvenient installation of the bottom cover, etc., to achieve the goal of installation Convenience, easy disassembly and assembly, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

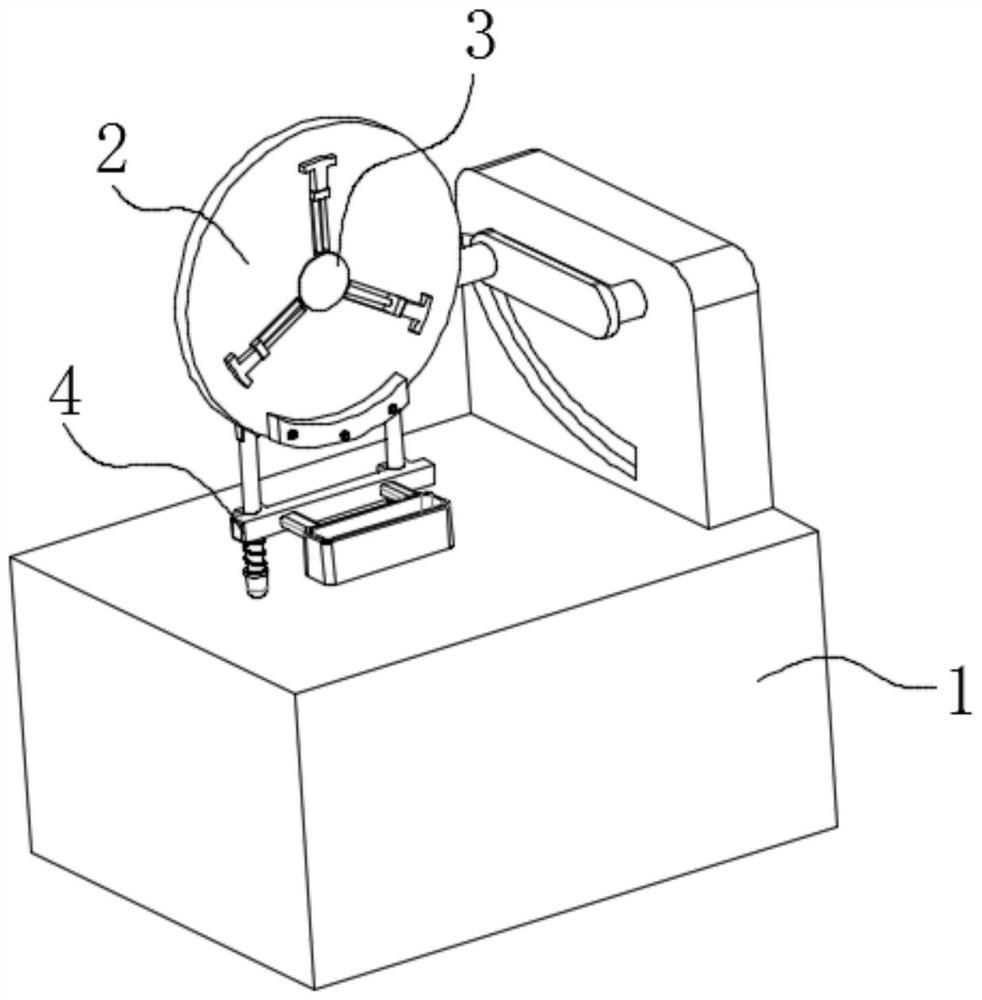

[0065] Embodiment one, with reference to Figure 1-10 , an auxiliary installation device for an internal combustion engine bottom cover, comprising: a flip-type assembly mechanism 1, an assembly tray 2, a three-jaw clamp assembly 3 and a clamp drive mechanism;

[0066] The driving arm of the overturning assembly mechanism 1 is connected with the assembly tray 2, and the overturning assembly mechanism 1 is used for the overturn adjustment of the assembly tray 2;

[0067] The three-jaw clamp assembly 3 is arranged on the drive assembly tray 2 for fixing the internal combustion engine placed on the assembly tray 2;

[0068] The clamp driving mechanism is set on the flip-type assembly mechanism 1, and the clamp drive mechanism is assembled to drive the three-jaw clamp assembly 3 to open and protrude when the flip-type assembly mechanism 1 drives the assembly tray 2 to perform flip adjustment, and cooperates with the flywheel to realize Fix the internal combustion engine on the as...

Embodiment 2

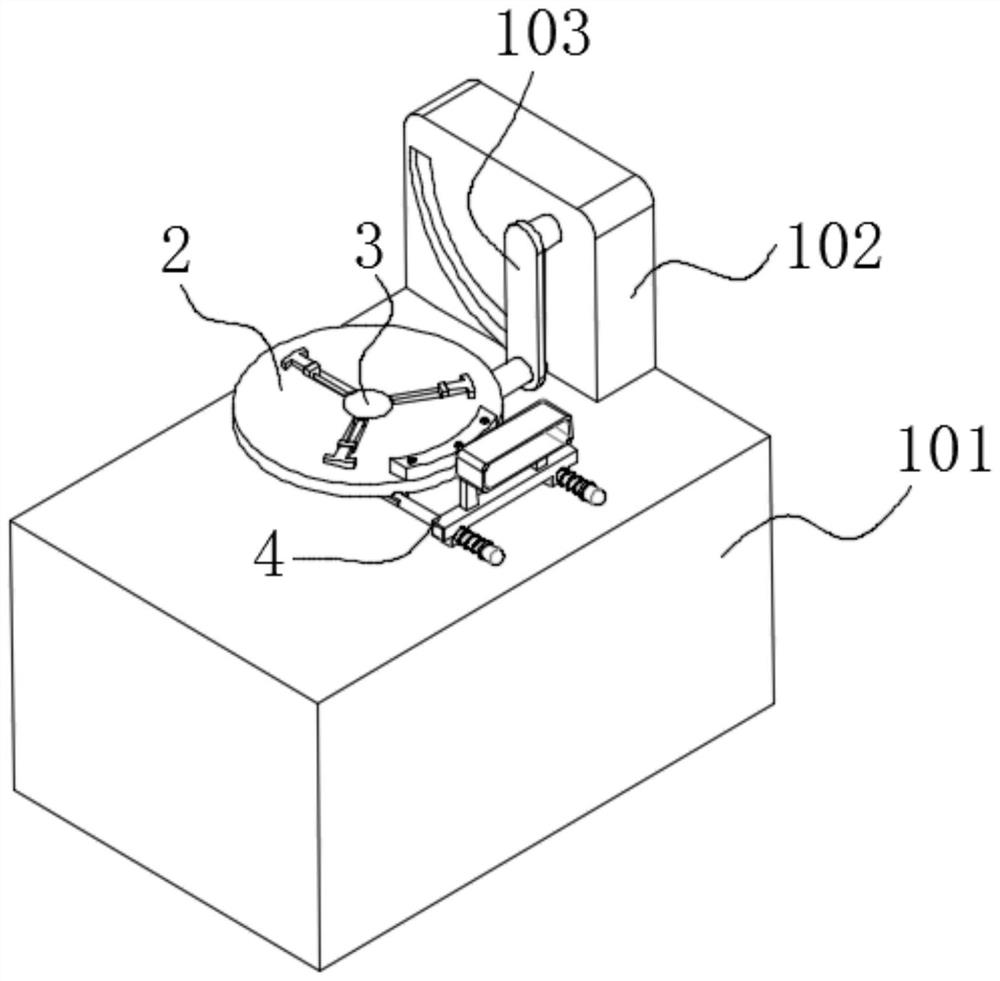

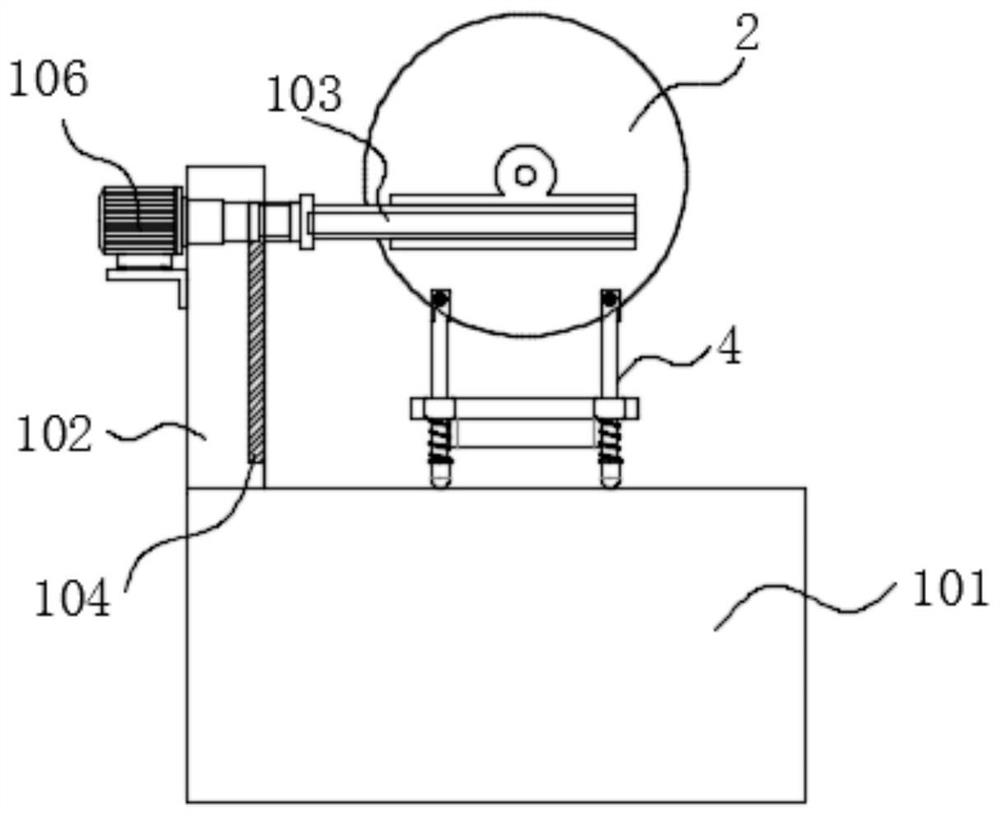

[0093] Embodiment two, refer to Figure 11-13 , an auxiliary installation device for an internal combustion engine bottom cover, comprising: a flip-type assembly mechanism 1, an assembly tray 2, a three-jaw clamp assembly 3 and a clamp drive mechanism;

[0094] The driving arm of the overturning assembly mechanism 1 is connected with the assembly tray 2, and the overturning assembly mechanism 1 is used for the overturn adjustment of the assembly tray 2;

[0095] The three-jaw clamp assembly 3 is arranged on the drive assembly tray 2 for fixing the internal combustion engine placed on the assembly tray 2;

[0096] The clamp driving mechanism is set on the flip-type assembly mechanism 1, and the clamp drive mechanism is assembled to drive the three-jaw clamp assembly 3 to open and protrude when the flip-type assembly mechanism 1 drives the assembly tray 2 to perform flip adjustment, and cooperates with the flywheel to realize Fix the internal combustion engine on the assembly t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com