A slotting, punching and cutting equipment for thermal insulation foam board

A foam board and insulation board technology, applied in the field of waste plastic recycling processing equipment, can solve the problems of excessive dust, reduced work efficiency, and low efficiency, and achieve the effects of ensuring the surrounding environment, ensuring processing efficiency, and preventing internal corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

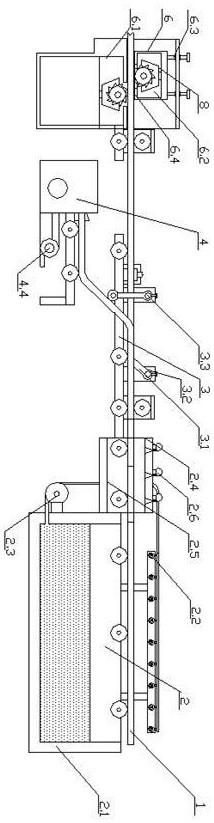

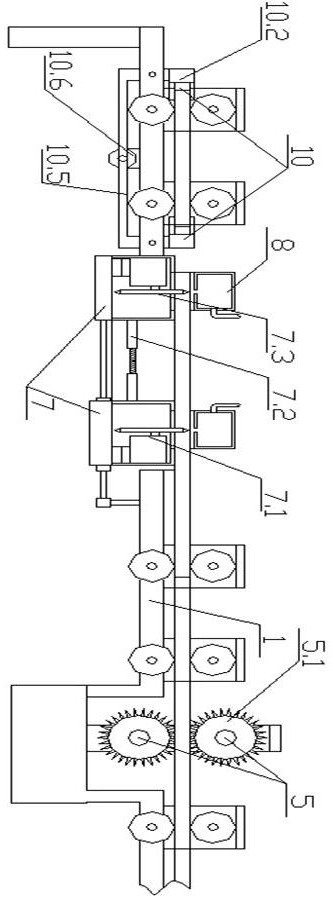

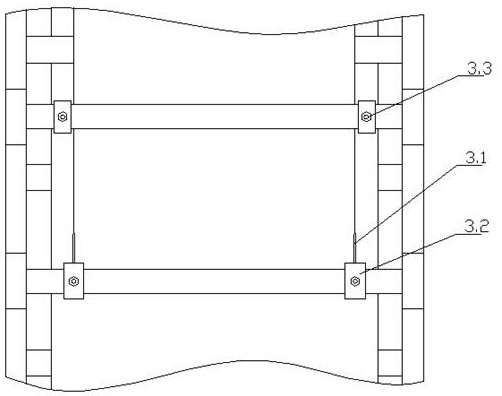

[0016] Conjunction with the drawings of the present invention is further illustrated.

[0017] like Figure 1-8As shown in a slotted insulation foam board, punch cutting apparatus, comprising a frame 1, the sheet cooling means 2, the edge cutting means 3 balance, reclaiming means 4, 5 the surface of the punch mechanism, the slotted mechanism 6 and slitting mechanism 7, that is, the gantry 1 through the fixed rack means, no particular shape, but with a plurality of the fixing means, the rack do not here in detail, is provided with a plurality of rollers on the frame 1 and a plurality of cylindrical rollers be driven by a drive assembly for transporting foam insulation board, cooling tank at the head of the frame fixed to 2.1 1, wherein the cooling plate comprises a cooling water tank 2 means 2.1, 2.2 and circulation assembly component spray 2.3, wherein 2.1 cooling water tank placed on the ground, the spray assembly disposed in a plurality of groups arranged side by side above the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com