Plastic raw material mixing preparation device

A technology for raw materials and plastics, applied in the field of plastic raw material mixing and preparation devices, can solve the problems of inability to fully mix raw materials, simple structure, low efficiency of diffusion and mixing of raw materials, etc., and achieves the effects of improving mixing and preparing efficiency, improving mixing and stirring effect, and avoiding sticking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

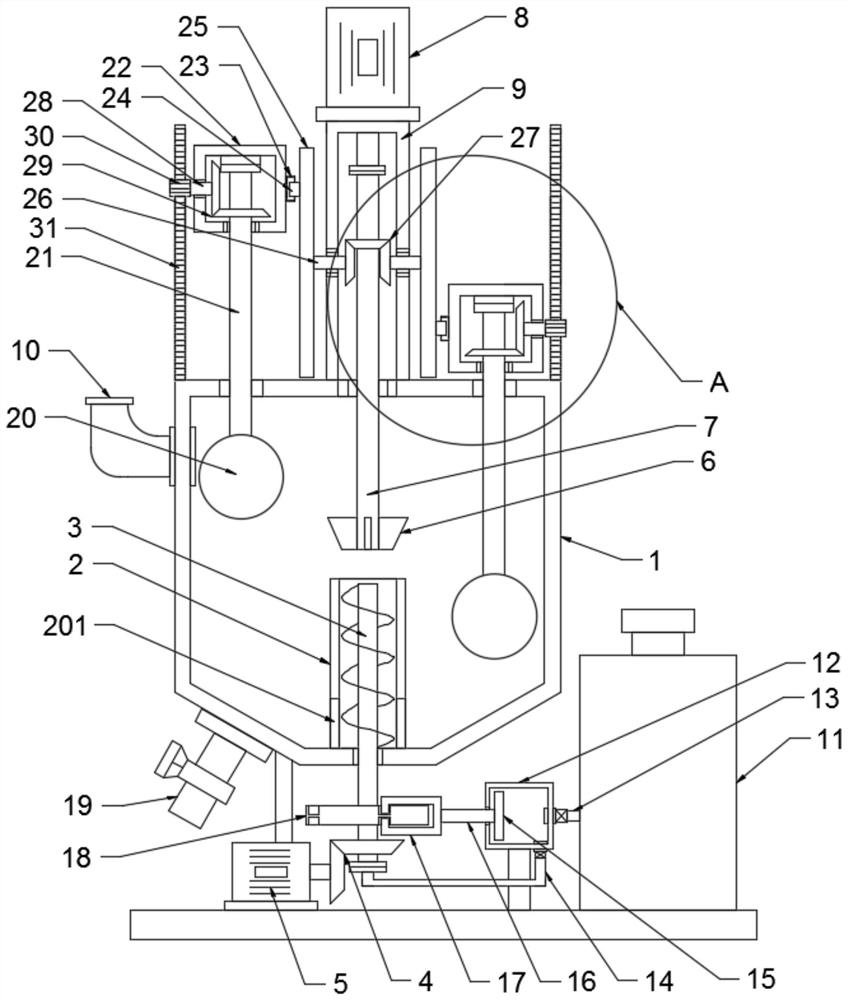

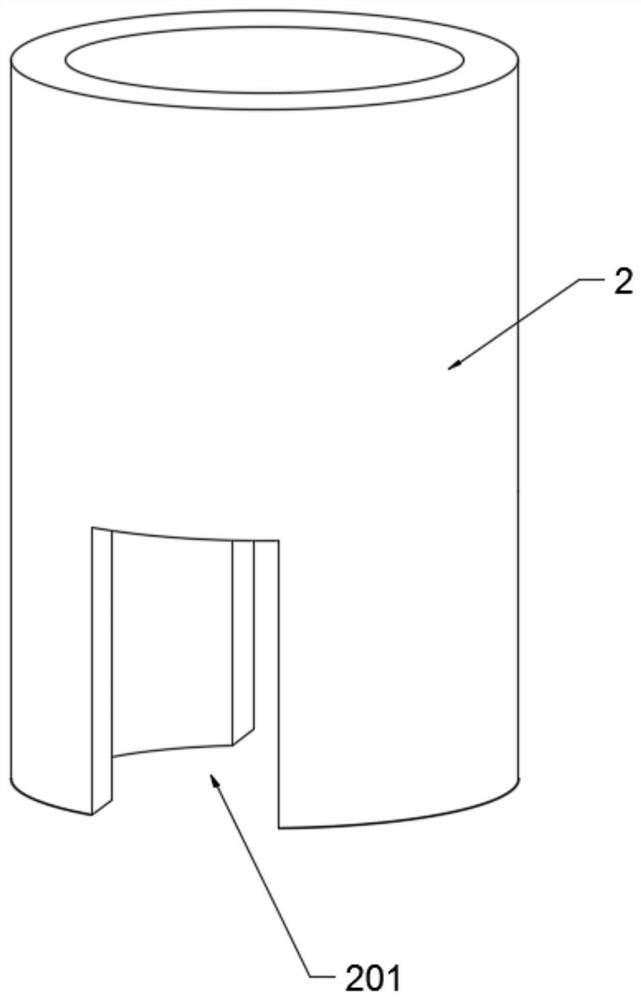

[0020] see Figure 1-4 , in an embodiment of the present invention, a plastic raw material mixing and preparation device includes a mixing box 1; a lifting cylinder 2 is arranged inside the mixing box 1, and the lifting cylinder 2 is fixedly connected to the bottom plate of the mixing box 1, and the lifting cylinder 2 is an opening at the upper end. Cylinder, the lower part of the lifting cylinder 2 is provided with a feed inlet 201, and the lifting cylinder 2 is nested with a spiral lifting roller 3, and the spiral lifting roller 3 penetrates the bottom plate of the mixing box 1 and is rotationally connected with the bottom plate of the mixing box 1; The lower end of the material roller 3 is connected to the output shaft of the first motor 5 through the first transmission gear set 4, and the first motor 5 drives the spiral lifting material roller 3 to rotate, and continuously pushes the raw materials in the lower part of the mixing box 1 upward, so that the materials in the mi...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is: in order to improve the mixing effect of viscous raw materials; the stirring box 1 is provided with stirring balls 20 distributed in a circle, and the upper end of the stirring ball 20 is fixedly connected with a lifting shaft 21, and the lifting shaft 21 Extending to the top of the mixing box 1, the lifting shaft 21 runs through the lifting frame 22 and is rotatably connected with the lifting frame 22 through the bearing seat; the inner side of the lifting frame 22 is fixedly connected with a chute plate 23, and the chute plate 23 is provided with a horizontally arranged slide Slot, chute plate 23 is nested with eccentric column 24, eccentric column 24 is fixedly connected with eccentric disc 25, eccentric disc 25 is fixedly connected with first transmission shaft 26, first transmission shaft 26 runs through mounting frame 9 and is connected with mounting frame 9 Rotational connection; the inner side of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com