Paper garbage recycling device

A recycling device and garbage technology, applied in garbage collection, trash cans, household appliances, etc., can solve the problems that the air cannot be completely discharged, and the paper garbage is not completely compressed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

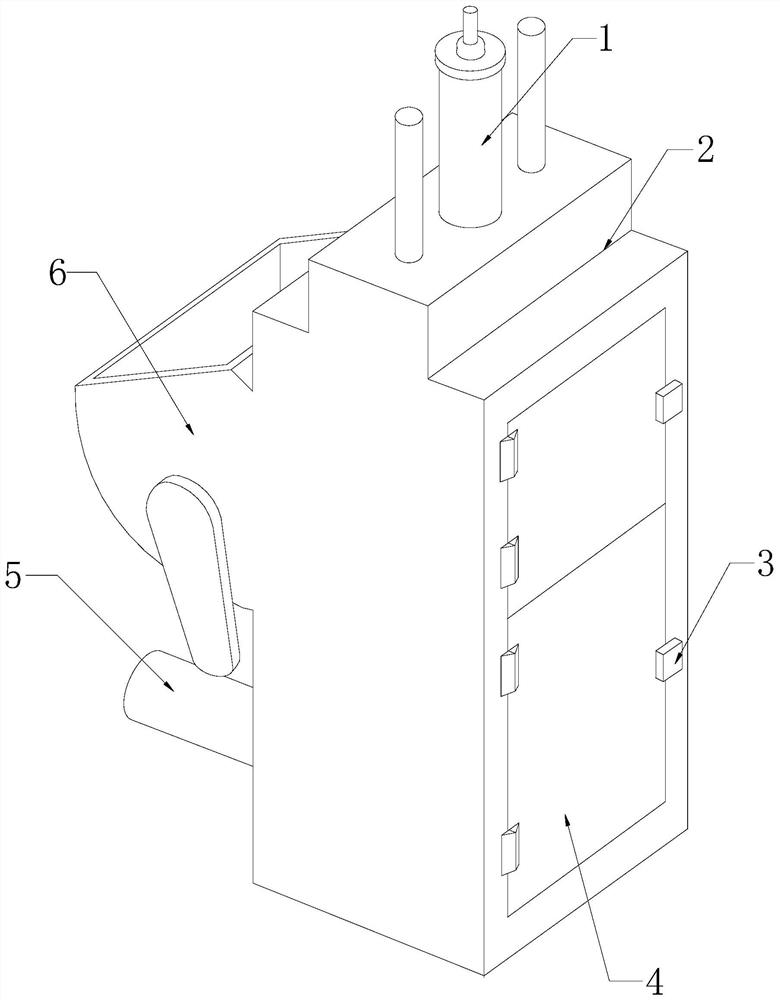

[0029] see Figure 1-Figure 5 , a paper garbage recycling device, the present invention provides a paper garbage recycling device, the structure of which includes a sliding rod 1, a body 2, a closing buckle 3, a closing door 4, a push plate slider 5, and a processing box 6. The sliding rod 1 is arranged on the top of the body 2, the closing door 4 is engaged with the body 2, the closing door 4 is connected with the closing buckle 3, the body 2 is mechanically connected with the processing box 6, and the push plate slides Block 5 is slidingly connected with body 2;

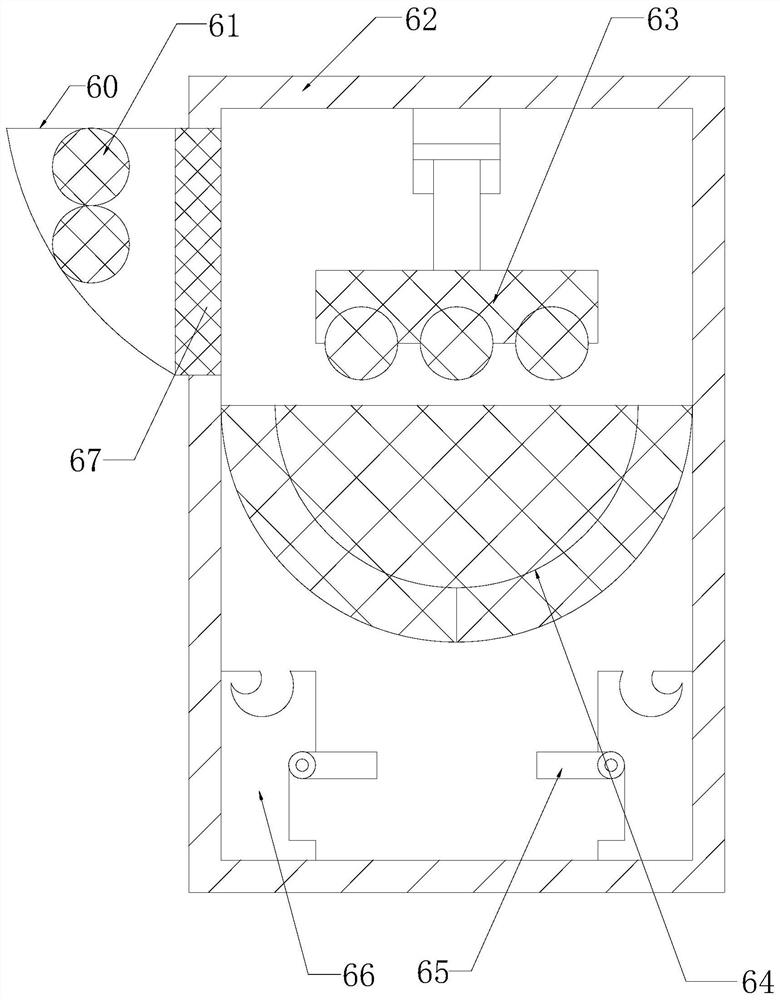

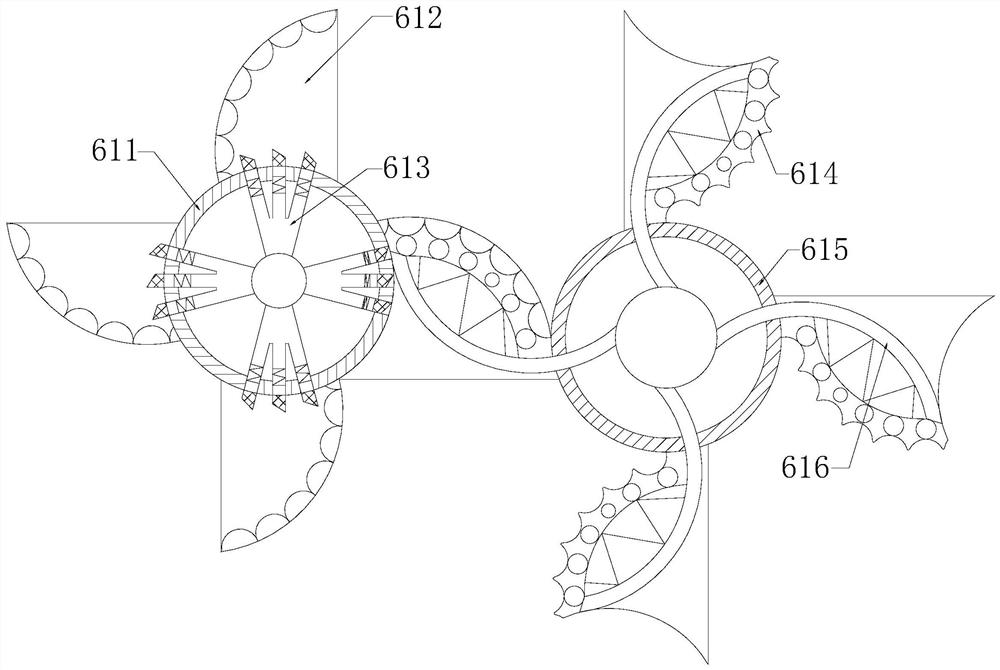

[0030] Described treatment box 6 is provided with feed chamber 60, rotary pressure device 61, casing 62, press down device 63, roller compactor 64, suction block 65, side wall 66, extruder 67, described feed chamber 60 is installed on the side of the box body 62, the front end of the feeding chamber 60 is provided with a pressure converter 61, the rear end of the feeding chamber 60 is provided with an extruder 67,...

Embodiment 2

[0038] see Figure 1-Figure 7 A paper garbage recovery device, the present invention provides a paper garbage recovery device, its structure includes a sliding rod 1, a body 2, a closing buckle 3, a closing door 4, a push plate slider 5, a processing box 6, the sliding The rod 1 is arranged above the machine body 2, the closed door 4 is engaged with the machine body 2, the closed door 4 is snapped connected with the closed button 3, the machine body 2 is mechanically connected with the processing box 6, and the push plate slider 5 is slidingly connected with the body 2;

[0039] Described treatment box 6 is provided with feed chamber 60, rotary pressure device 61, casing 62, press down device 63, roller compactor 64, suction block 65, side wall 66, extruder 67, described feed chamber 60 is installed on the side of the box body 62, the front end of the feeding chamber 60 is provided with a pressure converter 61, the rear end of the feeding chamber 60 is provided with an extrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com