A film loading mechanism of a film laminating machine

A technology of laminating machine and driving mechanism, which is applied in the direction of thin material processing, transportation and packaging, and winding strips, etc. It can solve the problems of reducing efficiency and difficult disassembly and replacement of film sleeves, and achieves a high degree of automation and improved replacement. Efficiency, convenient statistical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

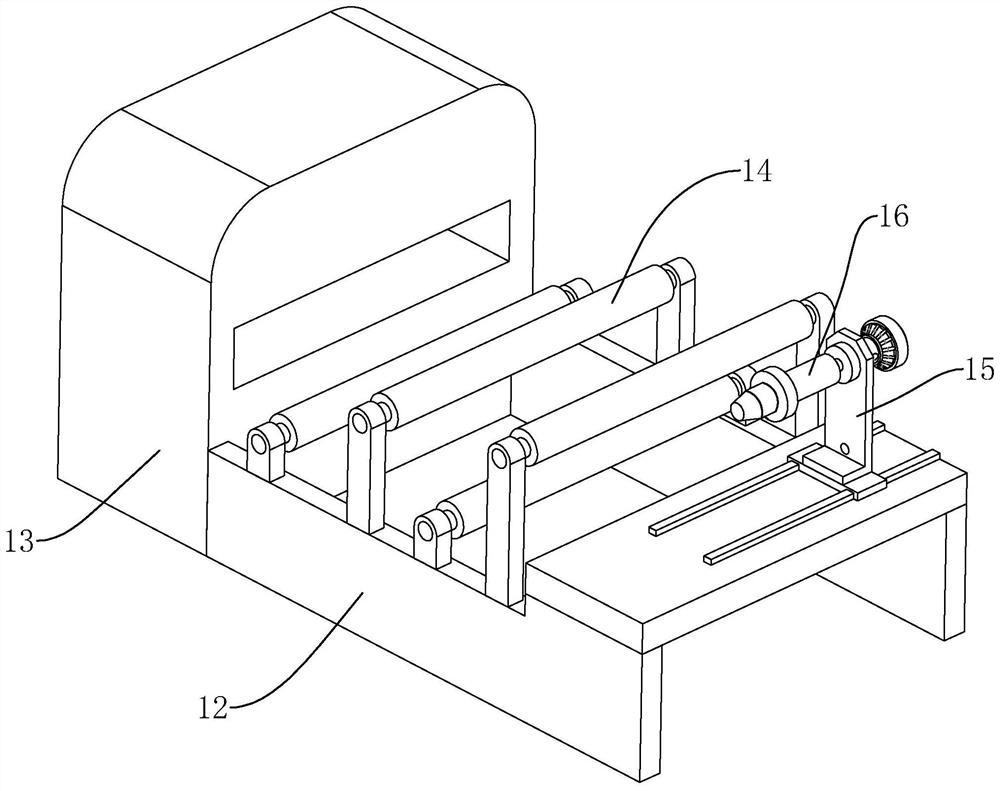

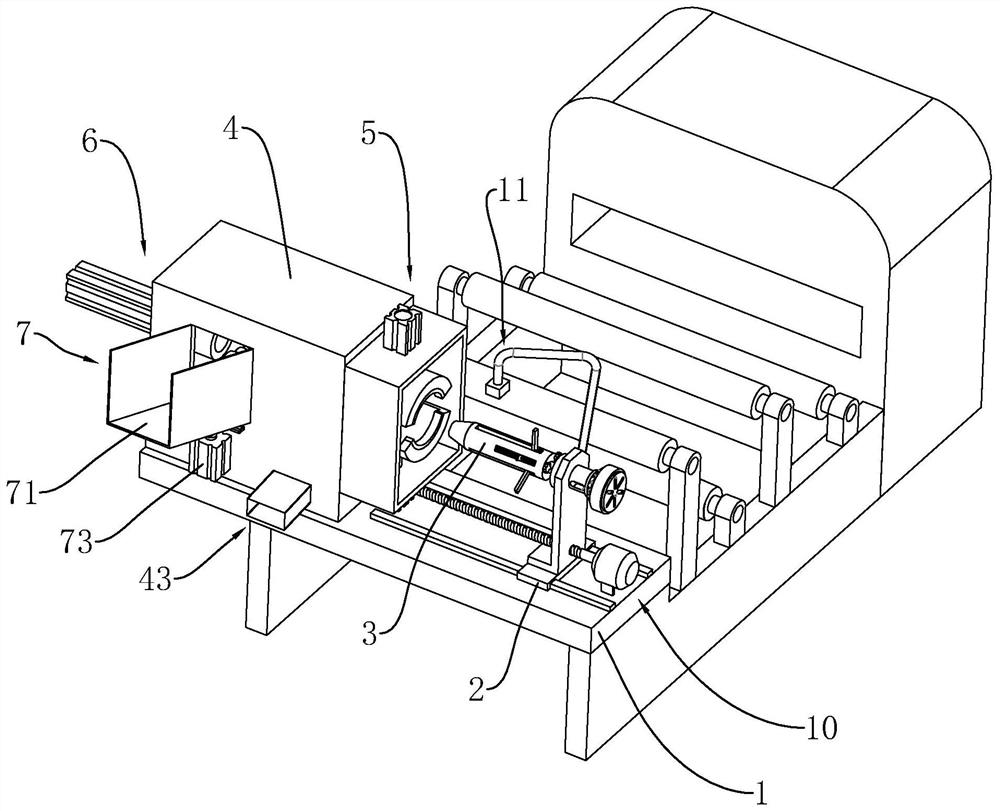

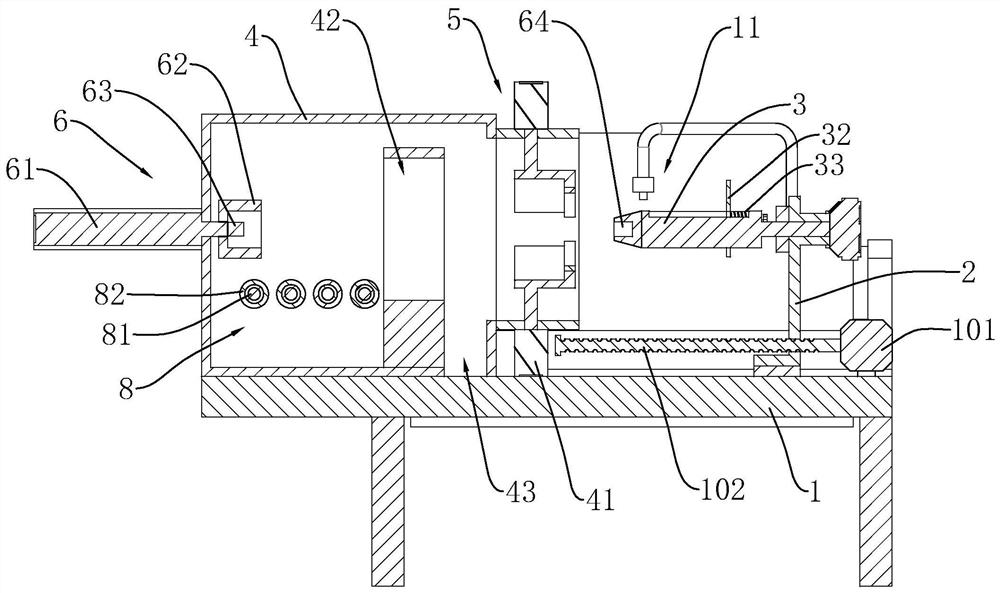

[0034] refer to figure 2 , image 3 , which is a laminating machine disclosed in the present invention, includes a mounting platform 1 whose upper surface is horizontally arranged. The upper surface of the mounting platform 1 is sequentially installed with an operating platform 4 and a vertically placed support from left to right. Seat 2. The upper end of the supporting base 2 is rotatably equipped with a horizontally placed rotating base 3 , the rotating base 3 is in the shape of a long tube and its front end faces the console 4 . The upper end of the support base 2 is also equipped with a servo motor whose output shaft is fixed to the central axis of the rotating base 3, and the rotating base 3 rotates vertically around its own central axis under the drive of the servo motor. In the console 4, a barrel loading mechanism 6, a barrel conveying mechanism 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com