A quantum dot polymer compound and its preparation method

A quantum dot and polymer technology, applied in the field of quantum dot polymer composite preparation, can solve the problems of quantum dot surface defects, aging, peeling, etc., and achieve the effect of improving aging resistance and ensuring aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

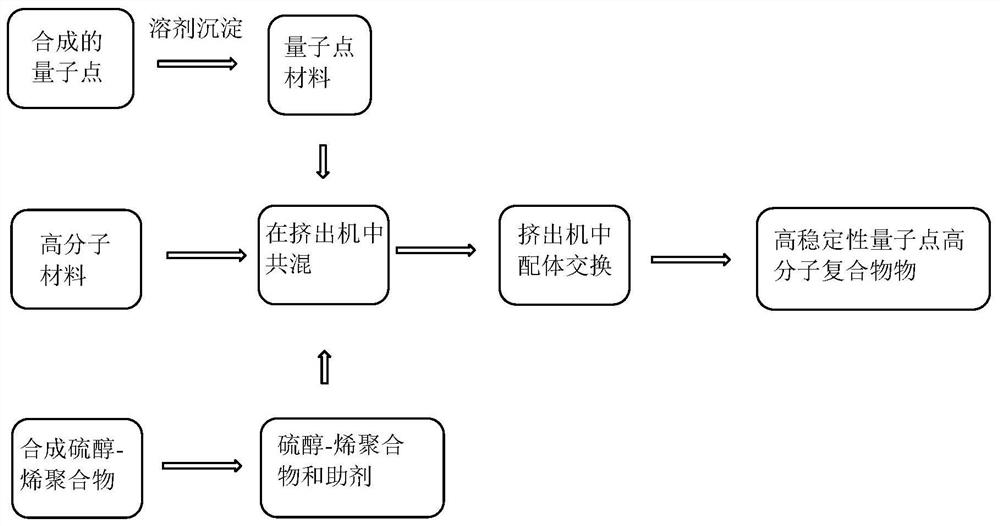

[0031] In order to solve the above technical problems, the present invention provides a method for preparing a quantum dot polymer compound, which is used to prepare a quantum dot polymer compound that does not cause ligand shedding. figure 1 shown, including the following steps:

[0032] Mix oil-soluble quantum dots, polymer materials, thiol-ene polymers and additives uniformly at processing temperature, and form quantum dot polymer composites after returning to room temperature.

[0033]In this embodiment, polymer materials are used as the environment, different ligand materials and quantum dot materials are put in, different ligand exchanges are performed on the surface of quantum dots, and finally a highly stable quantum dot polymer composite material is obtained.

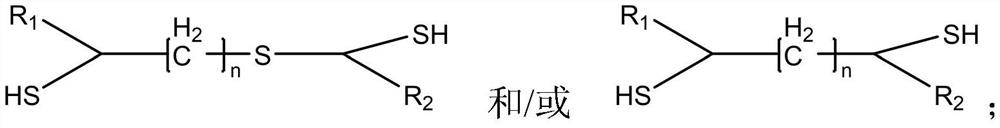

[0034] Specifically, the quantum dots are oil-soluble quantum dots, which can be selected from any one of the first compounds formed by elements in the II main group and the VI main group, the III main group an...

Embodiment approach 1

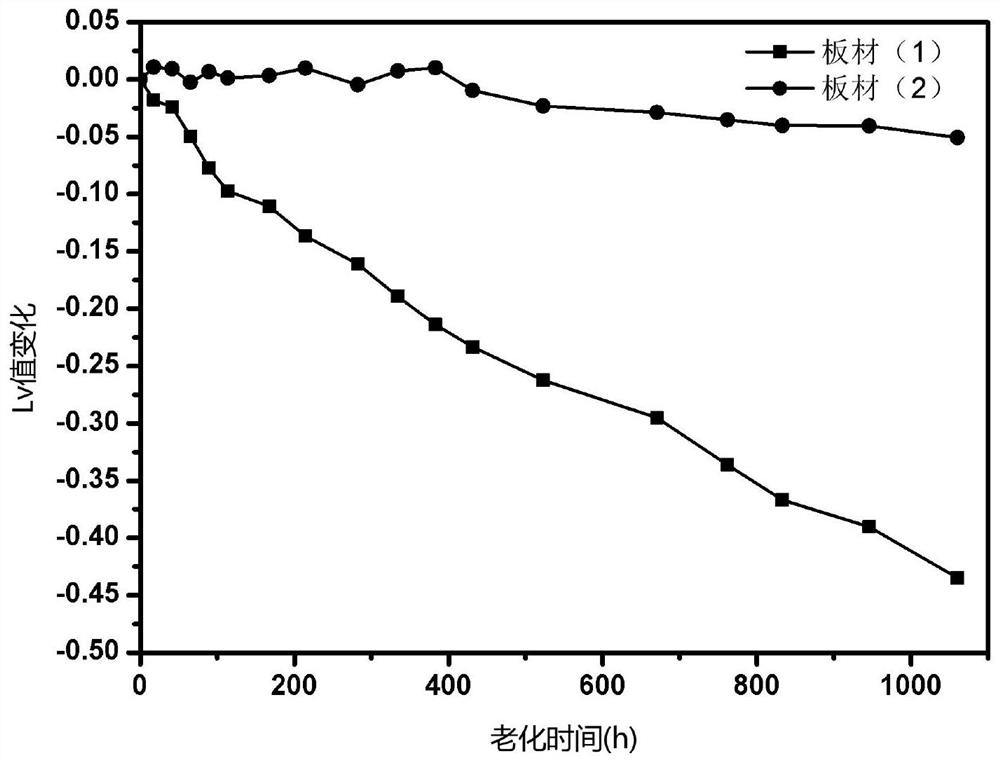

[0056] The ethanol solution was put into the quantum dot solution, and the volume ratio of ethanol to the quantum dot solution was 1:0.5, and centrifuged for 1 min to obtain the quantum dot material. 90% oleylamine and 10% oleic acid are used as surface ligands when the quantum dot material is prepared. Stir and mix polystyrene and quantum dot materials, thiol-ene polymer, dibutylhydroxytoluene and bis-2,2,6,6-tetramethylpiperidinol sebacate, and add them together to Mix in the screw extruder to form a mixture, wherein the mass ratio of quantum dots to the mixture is 5%, the mass ratio of the thiol-ene polymer to the mixture is 10%, and the mass ratio of dibutylhydroxytoluene to the mixture is 5%, The mass ratio of bis-2,2,6,6-tetramethylpiperidinol sebacate is 5%, the extrusion time is 300 seconds, and the average processing temperature is 180°C. After extrusion, cool to room temperature to form Solid quantum dot polymer composite.

[0057] The above-mentioned quantum dot p...

Embodiment approach 2

[0059] The ethanol solution was put into the quantum dot solution, and the volume ratio of ethanol to the quantum dot solution was 1:3, and centrifuged for 15 minutes to obtain the quantum dot material. Among them, 10% oleylamine, 50% oleic acid and 40% TOPO were put into the preparation of the quantum dot material as surface ligands.

[0060] Add polycarbonate, quantum dot material, thiol-ene polymer, tert-butyl hydroquinone and 2-(2-hydroxy-5-methyl-phenyl)-2H-benzotriazole to the extruder Mixing in the machine to form a mixture, wherein the mass ratio of quantum dots to the mixture is 0.01%, the mass ratio of thiol-ene polymer to the mixture is 0.1%, the mass ratio of dibutylhydroxytoluene to the mixture is 0.05%, and decane The mass ratio of bis-2,2,6,6-tetramethylpiperidinol ester is 0.05%, the extrusion time is 30 seconds, the average processing temperature is 350°C, and the solid quantum dots are formed after extrusion and cooled to room temperature. molecular complex....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com