Quick binding device for special-shaped high pier reinforcement cage

A steel skeleton, fast technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of high-altitude operation risks, long construction period, low construction efficiency, etc., to improve construction accuracy and quality control, and a wide range of applications , the effect of reducing security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

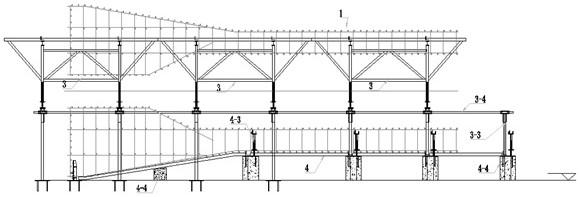

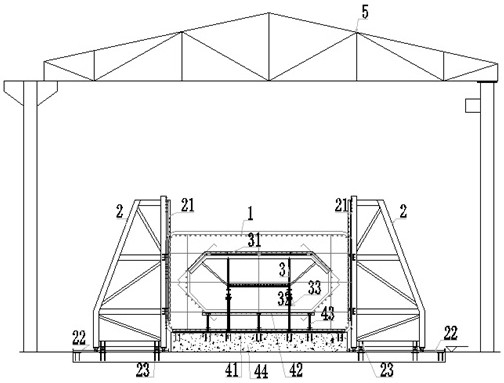

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is further described

[0021] A device and construction method for fast binding steel frame of special-shaped high pier, the device includes horizontally binding frame and ceiling, pier body steel frame 1 is bound on the horizontally binding frame. The horizontal binding tire frame is made up of outer tire frame 2, inner tire frame 3 and bottom tire frame 4. The bottom tire frame 4 is a fixed structure, the inner tire frame 3 is located on the bottom tire frame 4 top, the outer tire frame 2 is located on the bottom tire frame 4 both sides, the outer tire frame 2, and the inner tire frame 3 are all movable structures, which can realize structural flexibility. Quick installation and disassembly. After the reinforcement frame 1 is bound on the horizontal tire frame, after passing the inspection, it is hoisted away from the binding tire frame by lifting equipment, and the next process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com