Light chamber hybrid heating and refrigerating constant-temperature system

A technology of constant temperature system and optical chamber, applied in the field of spectrometer, can solve the problems of rising, single heating constant temperature, long heating time and temperature stabilization time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

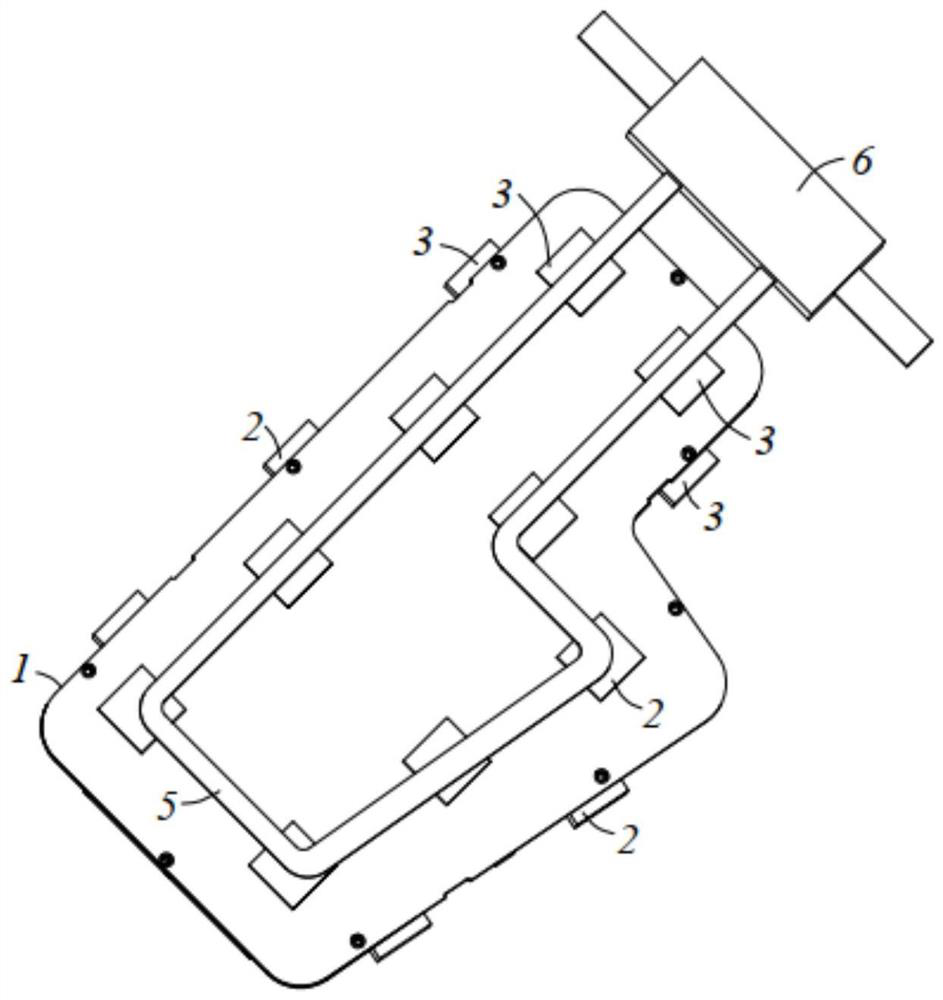

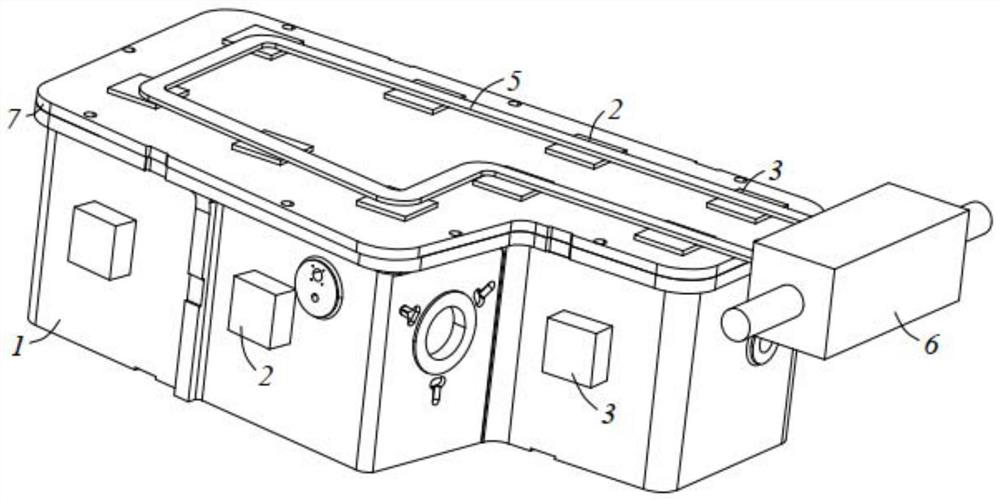

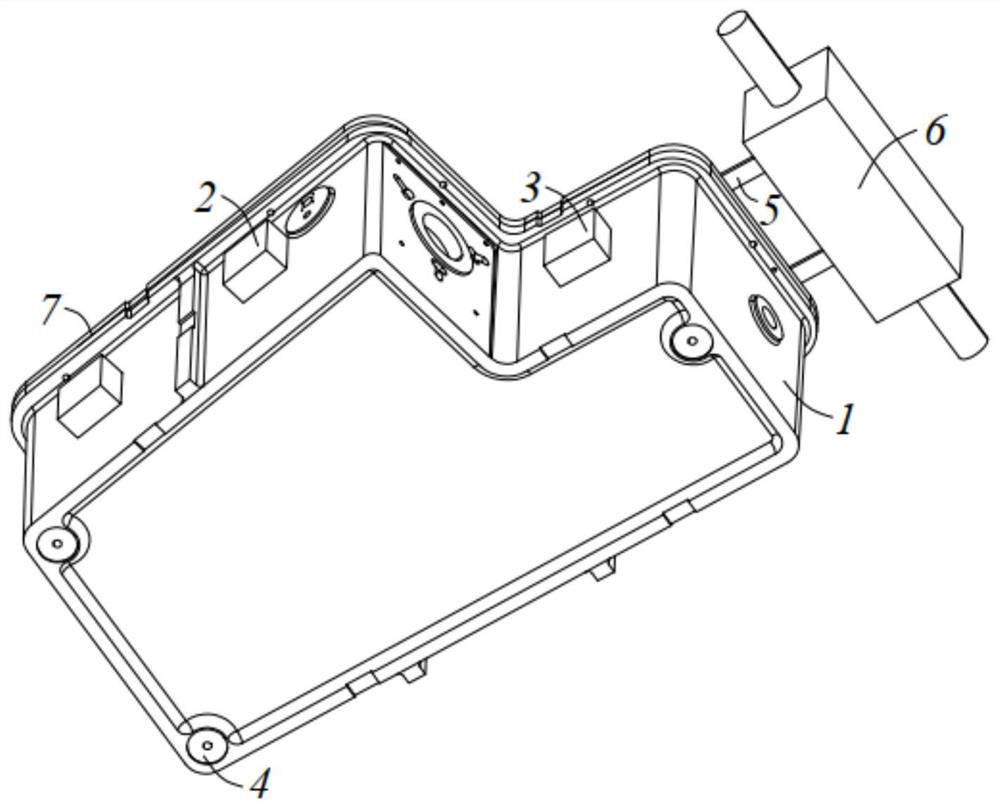

[0032] figure 1 , figure 2 and image 3 In order to solve the problems of the technologies described above, the present invention is achieved through the following technical solutions:

[0033] The mixed heating and cooling constant temperature system of optical chamber according to the present invention is applied to ICP spectrometer and is arranged beside the combustion chamber, such as figure 1 , figure 2 and image 3 As shown, it includes a light chamber 1, a number of heating elements 2, a temperature sensor corresponding to the heating elements 2, and an insulating material 7 arranged outside the light chamber 1. The light chamber 1 has a top surface, a bottom surface and a side surface, The bottom surface is partially concave to form a support part 4, the top surface is a plane, and the part between the top surface and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com