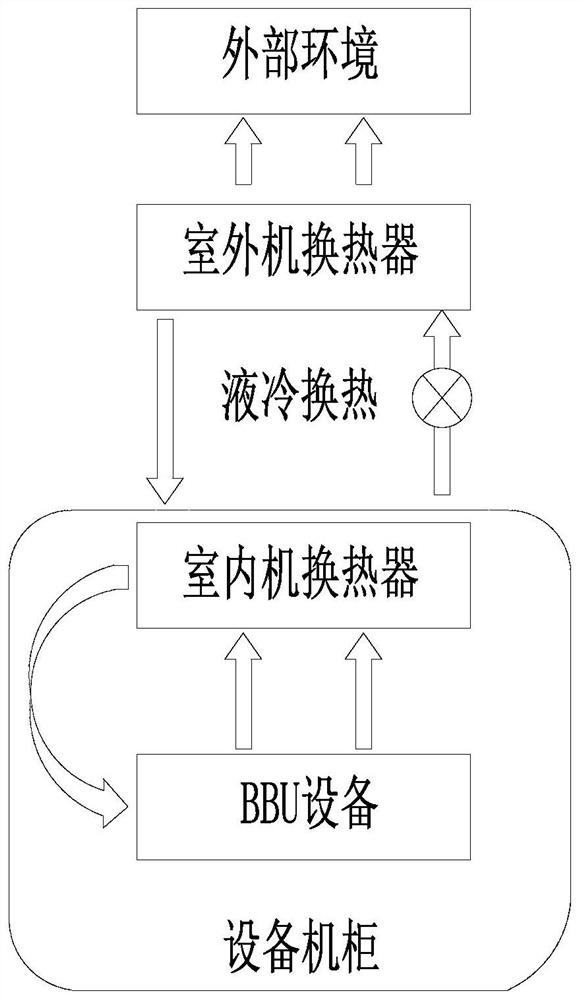

Liquid-cooled heat exchange system

A technology of cold and heat exchange and hot zone, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc. , to avoid the waste of heat leakage, shorten the heat flow path, and solve the effect of hot spot concentration and heat island effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

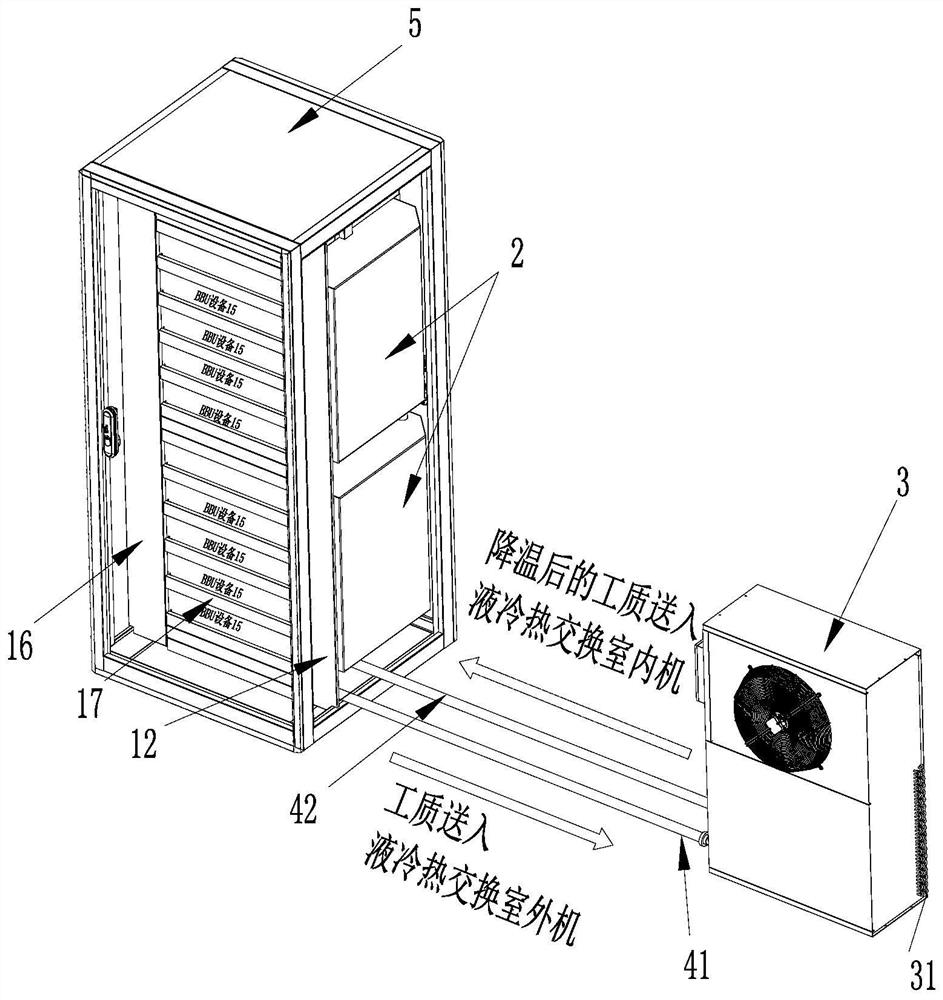

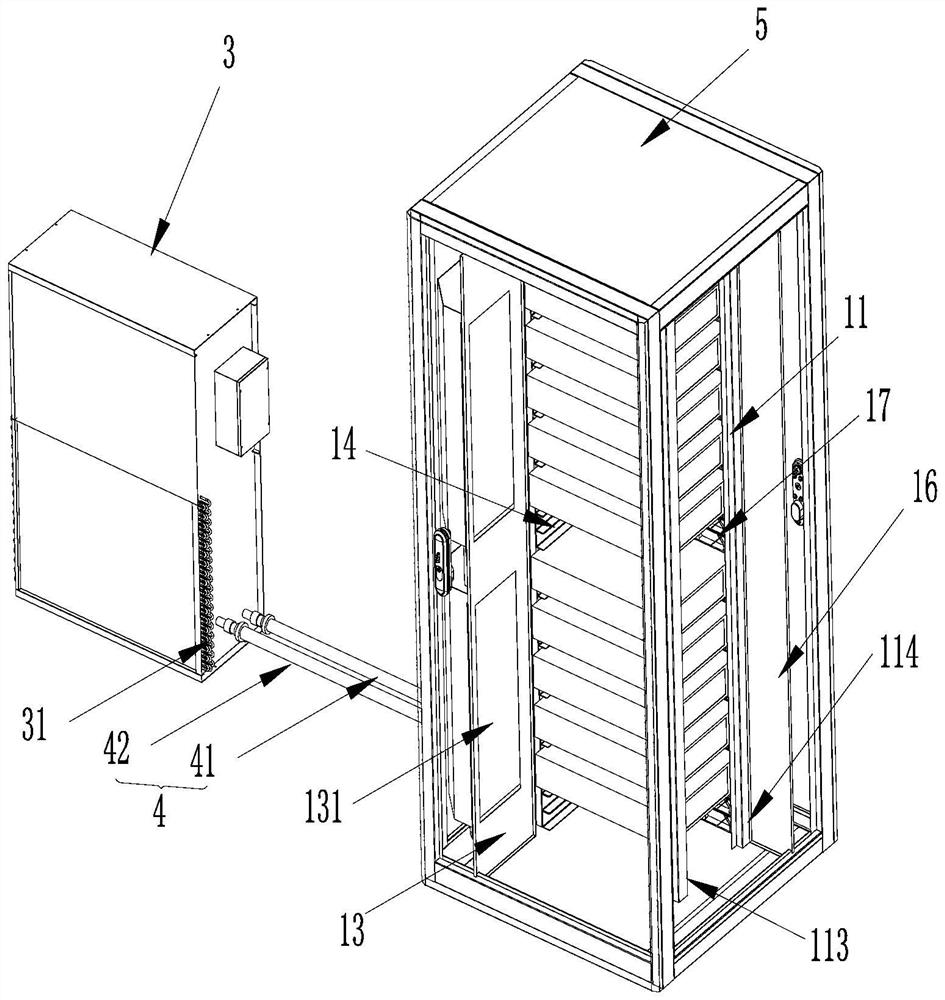

[0048] Furthermore, please also refer to Figure 2 to Figure 6 , as a specific embodiment of the liquid cooling heat exchange system provided by the present invention, the cabinet system includes an equipment carrying frame 11, a first partition 12, a second partition 13 and a first closing plate 14, the equipment The cabinet 5 includes a front cabinet door 51, a rear cabinet door 52, a left cabinet door 53 and a right cabinet door 54, and the equipment carrying frame 11 includes a first pillar 111, a second pillar 112, a third pillar 113 and a fourth pillar 114 ; The first pillar 111, the second pillar 112, the third pillar 113 and the fourth pillar 114 encircle the equipment carrying frame 11 in turn, and the equipment carrying frame 11 is installed in the equipment cabinet 5, so A plurality of BBU devices 15 are placed on the device carrying rack 11, the first closed plate 14 is arranged between two adjacent BBU devices 15, and the first closed plate 14 and the BBU device 1...

specific Embodiment approach

[0051] Furthermore, please also refer to Figure 2 to Figure 6 , as a specific embodiment of the liquid cooling heat exchange system provided by the present invention, the cabinet system further includes a third partition 16 and a second closing plate 17;

[0052] The third partition 16 is arranged between the fourth pillar 114 and the left cabinet door 53, the second closing plate 17 is arranged between two adjacent BBU devices 15, and the third partition The plate 16 and the second closing plate 17 are all coplanar with the front side of the BBU equipment 15; , and the area surrounded by the front cabinet door 51 is the front isolation area 18; the left area of the BBU equipment 15 communicates with the rear side area of the BBU equipment 15, and the second partition 13, the second The area enclosed by the three partitions 16 , the BBU equipment 15 , the equipment carrying rack 11 , the left cabinet door 53 and the rear cabinet door 52 is a cold zone 56 .

[0053] Exem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com