Preparation process of environment-friendly water-permeable brick

A preparation process and technology of permeable bricks, which are applied in the field of preparation of environmental protection permeable bricks, can solve problems such as high production cost, low production efficiency, waste, etc., achieve good economic and environmental protection benefits, solve the problem of heat island effect and waterlogging, good water seepage Sexual and moisturizing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

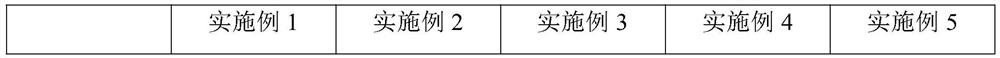

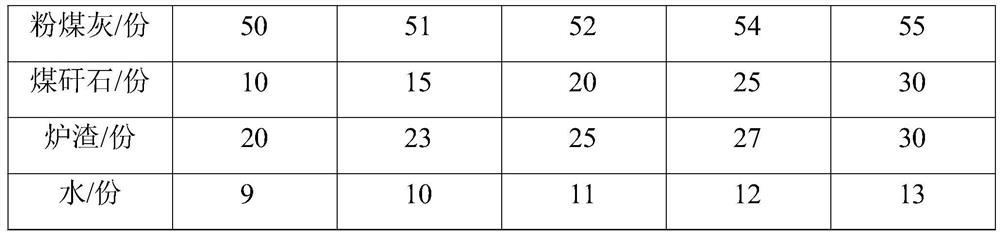

[0023] Examples 1-5 are used to illustrate the components of cement grinding aids. The components of the environment-friendly permeable bricks in Examples 1-5 are shown in Table 1.

[0024] Table 1, the component table of embodiment 1-5 environmental protection permeable brick material

[0025]

[0026]

[0027] In combination with Table 1, the preparation method of the environment-friendly permeable brick of Examples 1-5 is described in detail below.

[0028] A preparation process of an environmentally friendly permeable brick, comprising the steps of:

[0029] Step 1: After dehydrating and drying the coal gangue, crush it with a jaw crusher, grind it with a disc and pass it through a 200-mesh sieve; pass the slag through a 200-mesh sieve.

[0030] Step 2: In parts by weight, 50-55 parts of fly ash, 10-30 parts of coal gangue and 20-30 parts of slag are weighed and mixed, sprayed with water and stirred to obtain a billet.

[0031] Step 3: Add the mixed and stirred bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com