Cutting device for grafting solanaceae vegetables

A cutting device and vegetable technology, applied in grafting and other directions, can solve the problems of inaccurate control of cutting distance, easy to cut fingers, etc., and achieve the effect of avoiding inaccurate cutting positioning and high cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

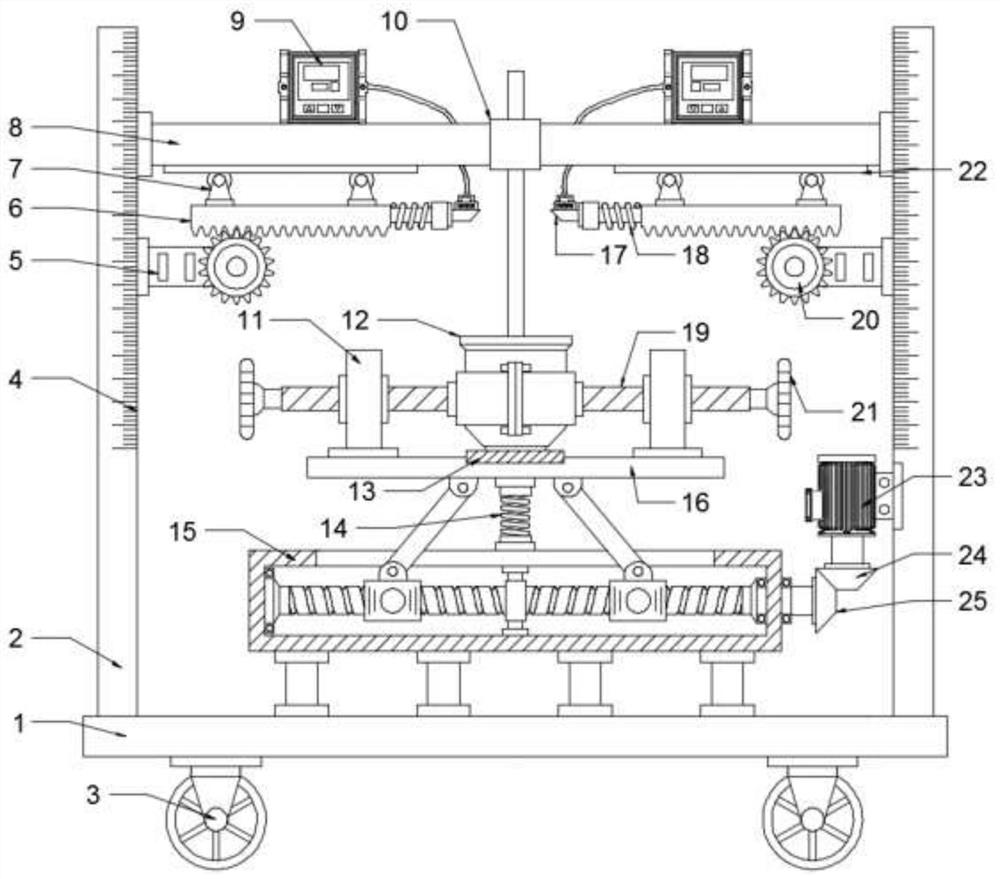

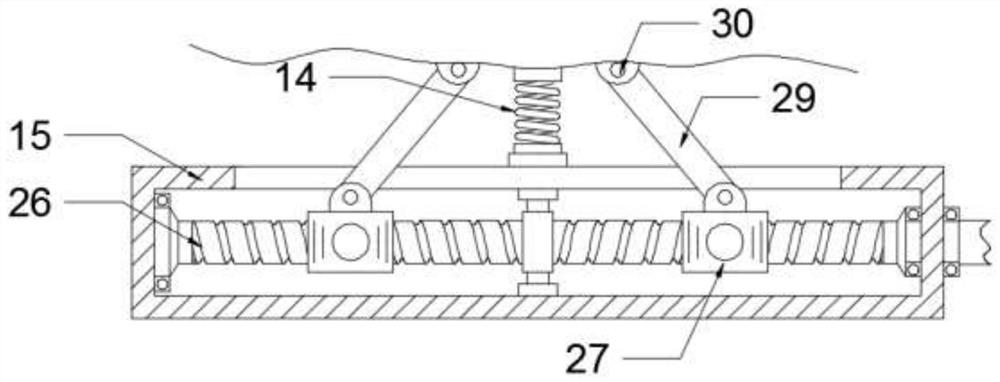

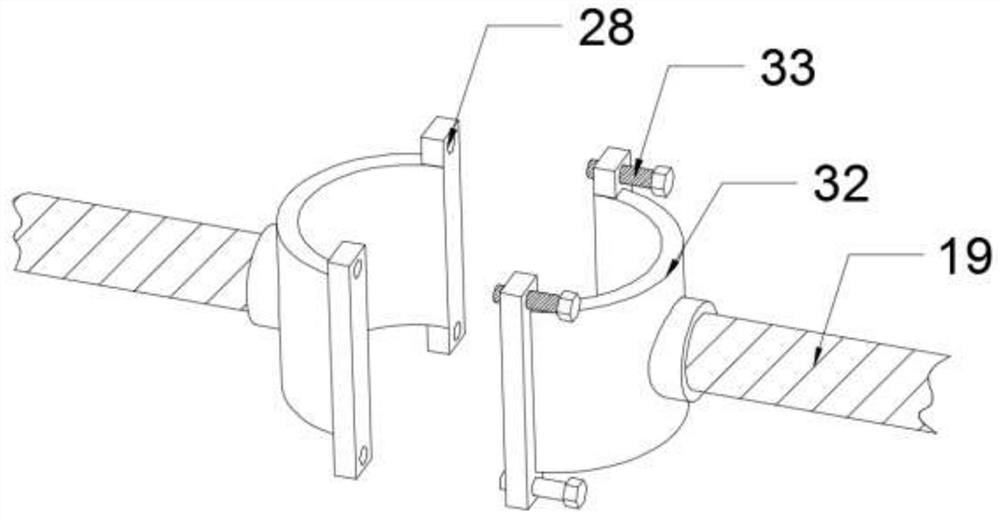

[0024] see Figure 1-4 , a cutting device for grafting Solanaceae vegetables, comprising a base 1 and a cutter 17, brackets 2 are symmetrically arranged on the left and right sides of the upper surface of the base 1, the bracket 2 and the base 1 are fixedly connected by welding, and the left and right sides The lifting box 15 is set between the two supports, and the lifting box 15 is fixedly connected with the base 1 through a connecting rod. The screw rod 26 is arranged in the lifting box 15, and the screw rod 26 is rotatably connected with the inner walls of the left and right sides of the lifting box 15. Screw rod 26 left and right sides thread direction is opposite, described screw rod 26 surface left and right sides symmetrically set movable seat 27, described movable seat 27 can move in horizontal direction along with the rotation of screw rod 26, described screw rod 26 right end passes through lift Box 15 is extended and fixedly connected to bevel gear 1 25, and drive m...

Embodiment 2

[0033] see Figure 1-2, on the basis of embodiment 1, in order to carry out raising and lowering to Solanaceae vegetable cultivation pot 12, adjust stem branch to suitable distance and then cut, rotate by driving motor one 23, and described driving motor one 23 drives bevel gear two 24 to rotate , the bevel gear two 24 drives the bevel gear one 25 to rotate, and the bevel gear one 25 drives the screw rod 26 to rotate, and the movable seats 27 on the left and right sides are close to or far away from each other on the surface of the screw rod 26. 30 promotes the cutting platform 16 to move up and down in the vertical direction to realize the lifting of the Solanaceae vegetable cultivating pot 12.

[0034] Further, in order to improve the stability of the cutting platform 16 during the up and down movement, in this embodiment, a damping spring 14 is fixedly installed between the cutting platform 16 and the lifting box 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com