Black tea fermentation equipment capable of carrying out turn-over

A fermenting equipment and black tea technology, which is applied in the field of black tea fermenting equipment that can be turned over, can solve the problems of uneven fermentation of black tea, black tea cannot be fixed, tea leaves fall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

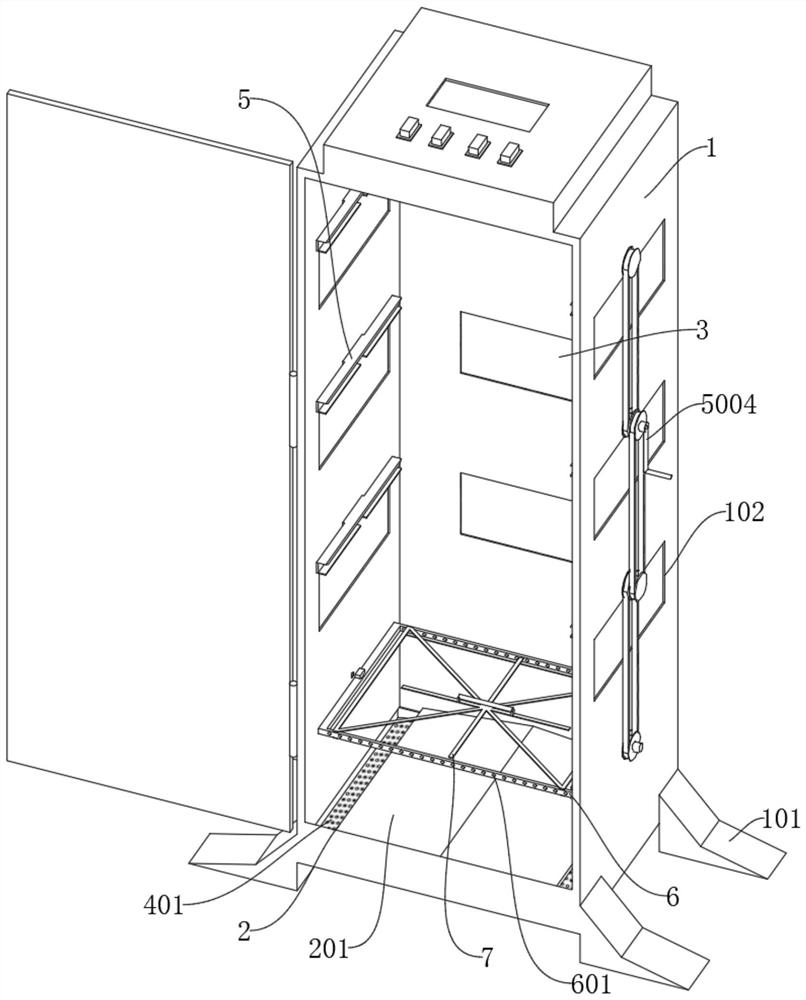

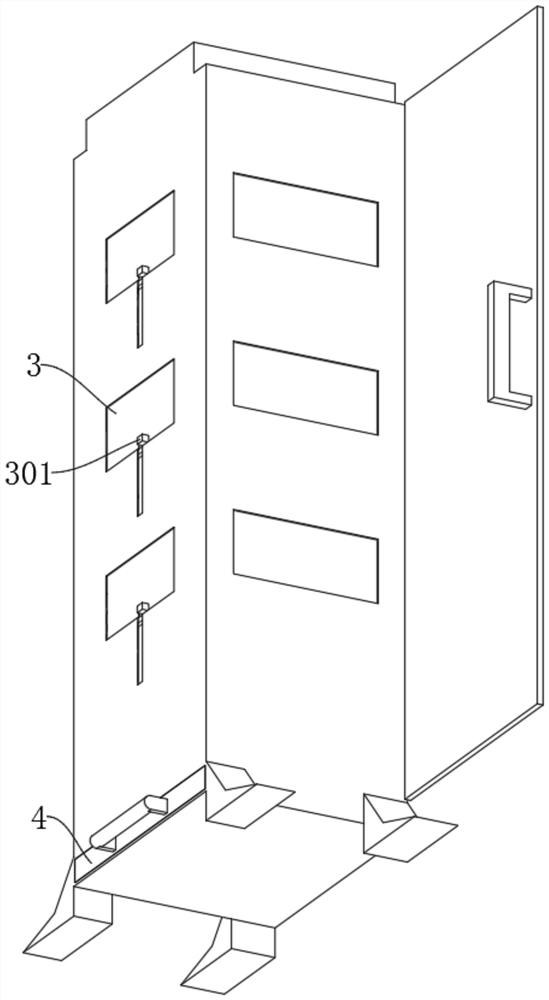

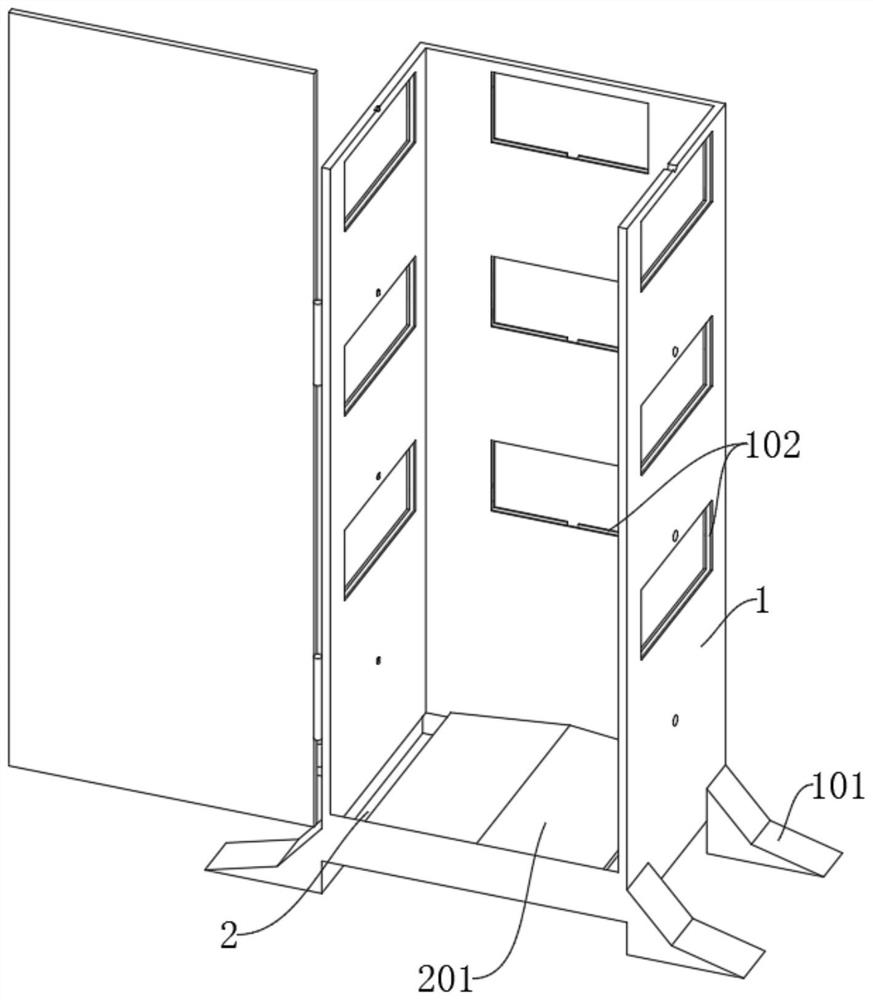

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The invention provides a kind of black tea fermentation equipment that can be turned over, comprising a main body 1, a bottom tank 2, a moving plate 3, a pull bin 4, a rotating part 5, an installation part 6 and a pressing part 7; the main body 1 is a rectangular structure, and the main body The front end of 1 is provided with a sealed door, and the top of the main body 1 is provided with a controller; the bottom groove 2 is set in the middle of the bottom of the main body 1; the moving plate 3 is installed inside the side groove 102 of the main body 1, and the moving block of the moving plate 3 302 is inserted inside the pulling groove; the pulling bin 4 is provided with a pulling piece at the outer end, and the pulling bin 4 is embedded and installed inside the bottom groove 2; the pressing piece 7 is installed above the mounting piece 6, and the clamping plate 701 of the pressing piece 7 Embedded installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com