Battery module charging maintenance fixture

A battery module and fixture technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., and can solve problems such as battery module falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

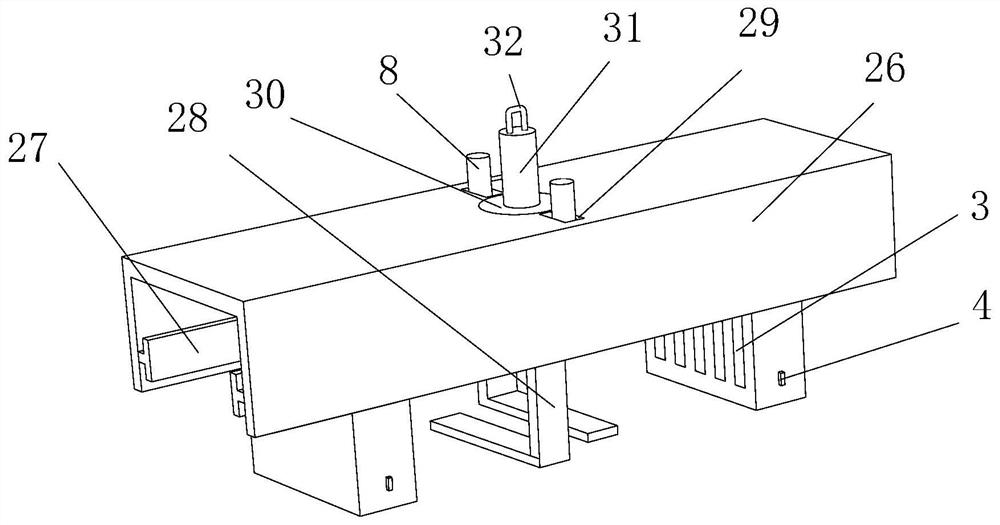

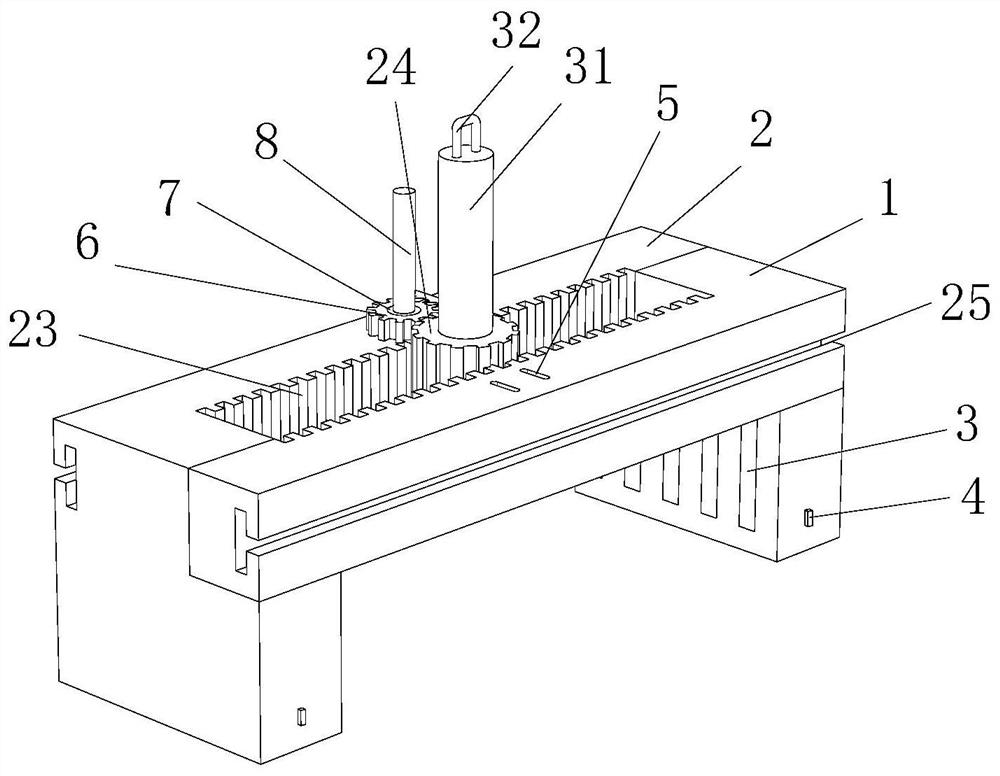

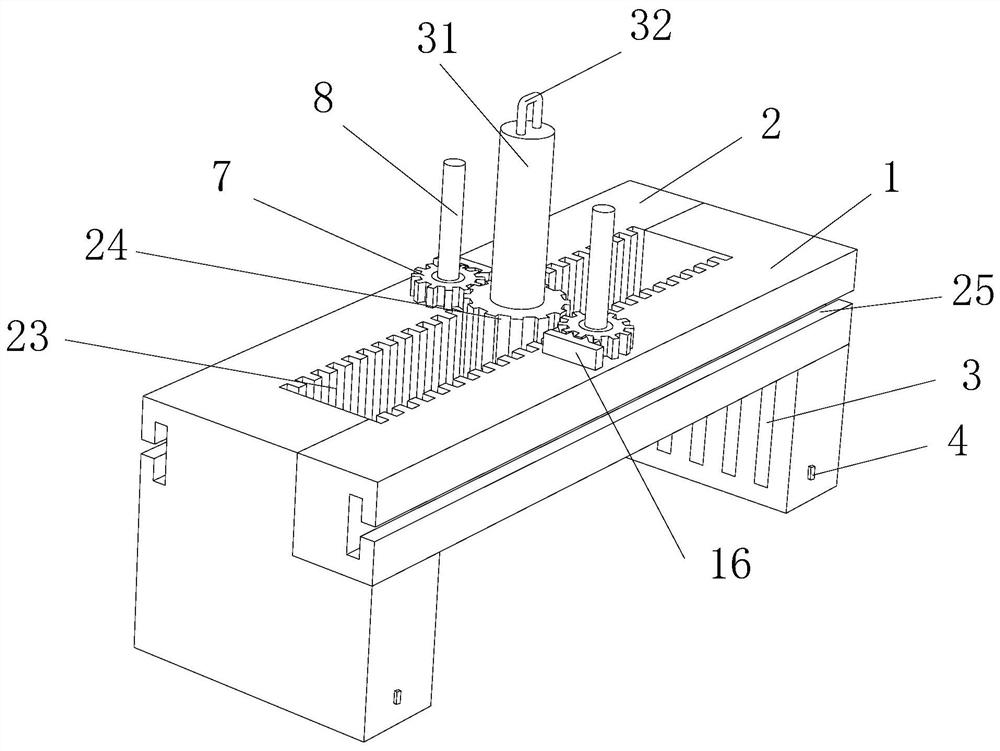

[0028] Example: such as Figure 1-Figure 7 As shown, the battery module charging and maintenance fixture includes a first splint 1, and the first splint 1 is composed of a set of rectangular strips and a set of rectangular plates, wherein the rectangular strips on the first splint 1 and the rectangular plates on the first splint 1 meet The near side wall surface is fixedly connected with the corresponding position on the front side of the rectangular plate on the first clamping plate 1, wherein the front side wall surface of the rectangular plate on the first clamping plate 1 is provided with a rectangular groove at the end far away from the rectangular bar on the first clamping plate 1, The left side of the first splint 1 is provided with a second splint 2, the second splint 2 is composed of a set of rectangular strips and a set of rectangular plates, wherein the side of the second splint 2 where the rectangular strips and the connecting block 12 rectangular plates approach T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com