Desilting, blowing and sand sucking device for construction of bridge foundation steel cofferdam

A bridge foundation, air blowing and sand suction technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of poor maneuverability of sand suction ships, weak sand suction ability, underwater mud and sand erosion, etc., and achieve simple structure, Good economy and avoid stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

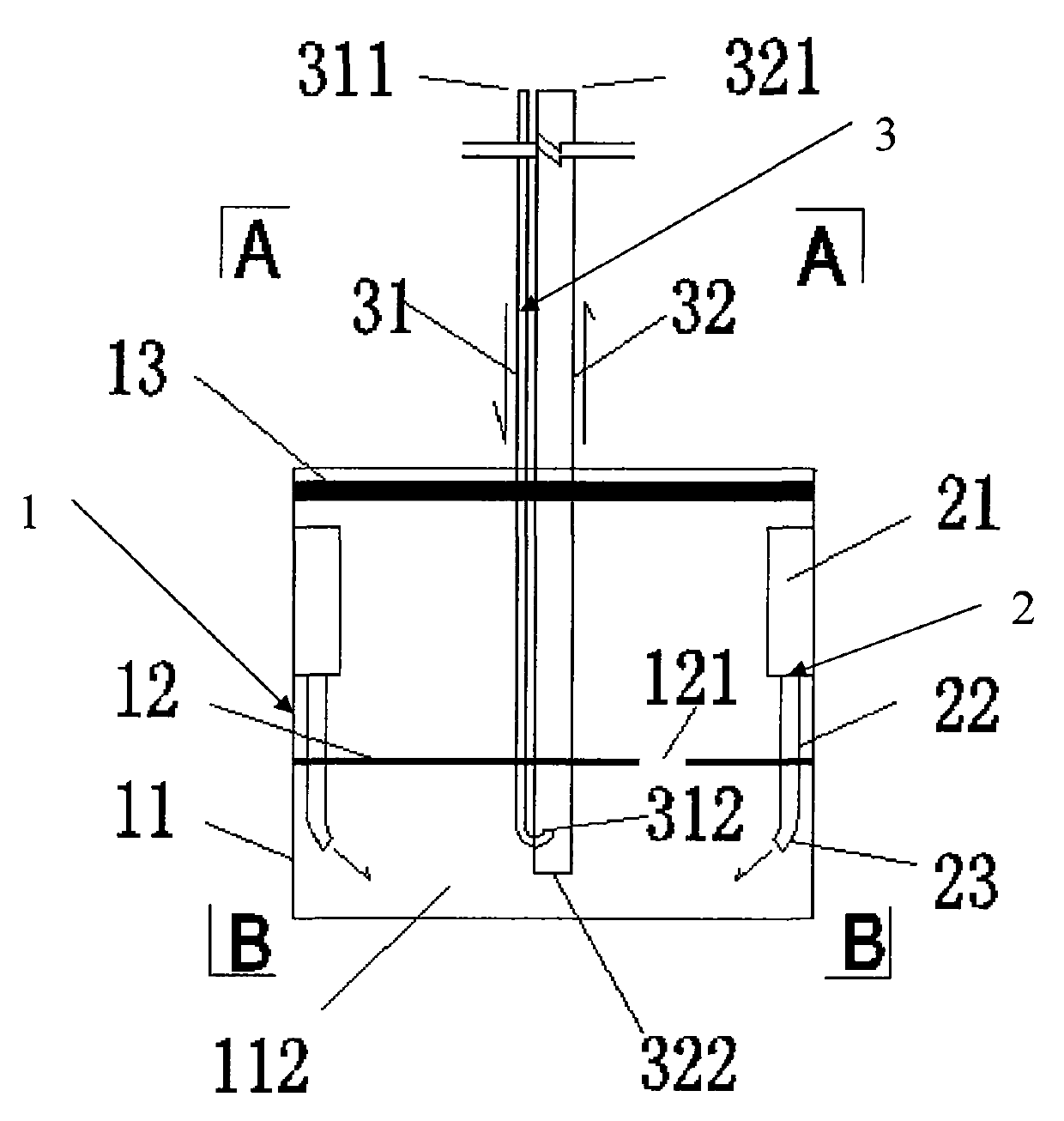

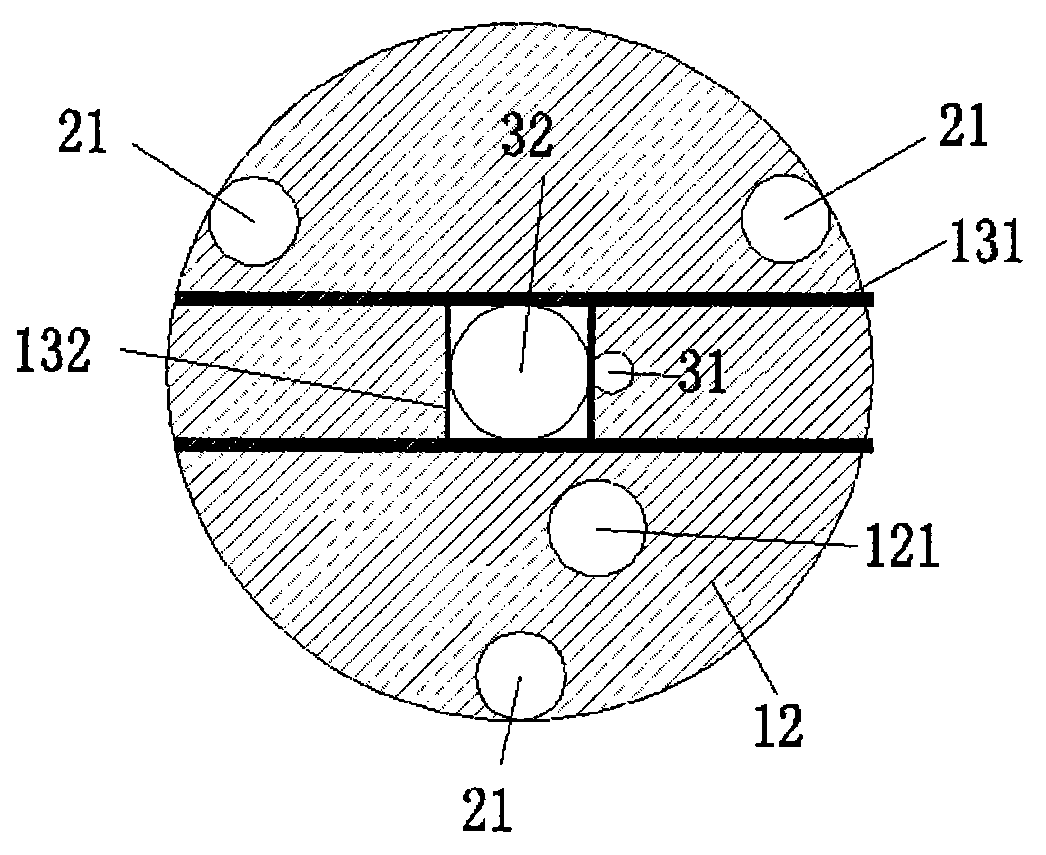

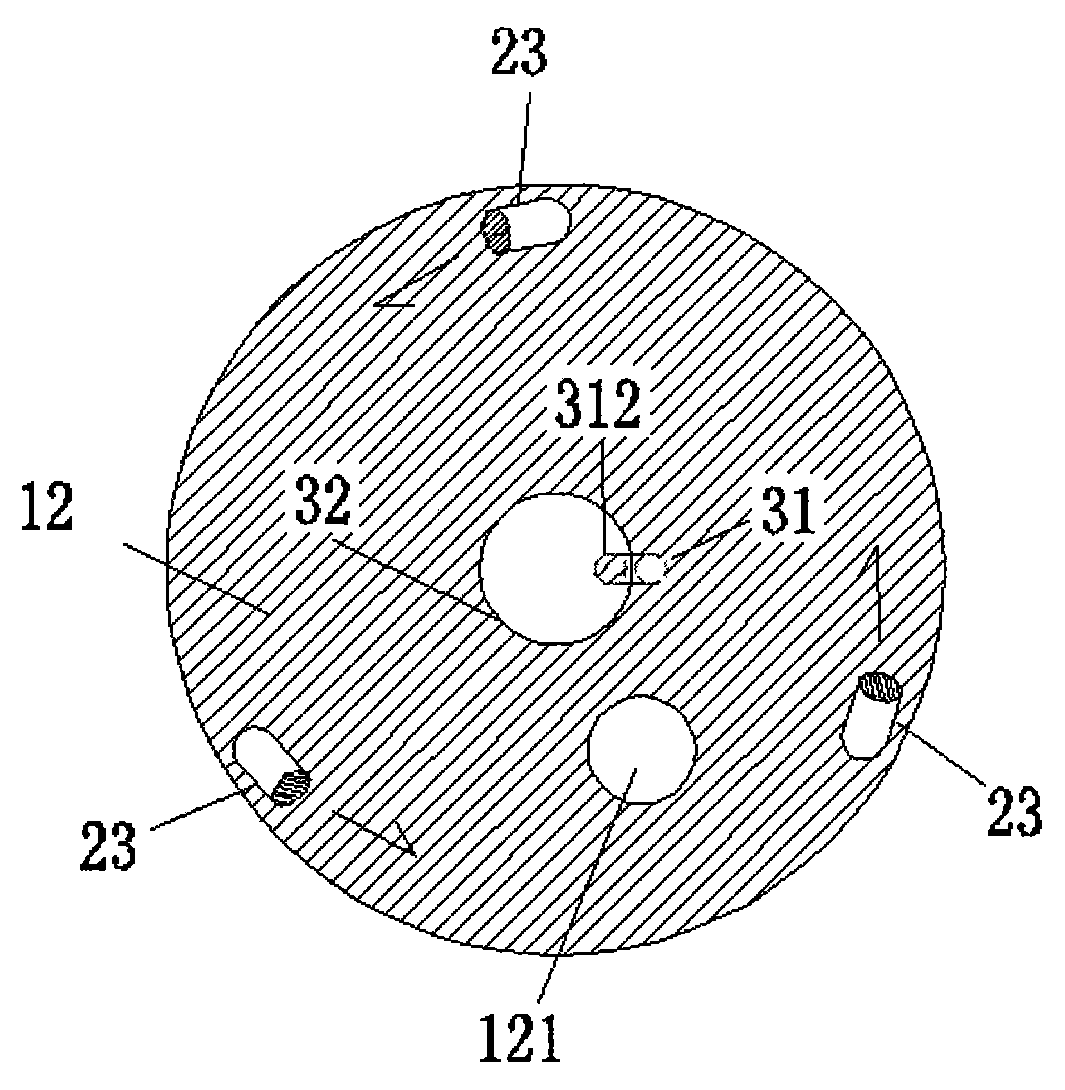

[0022] Such as figure 1 , 2 As shown in . and 3, the air-blowing and sand-absorbing device for bridge foundation steel cofferdam construction includes a cover body 1, a sand-washing device 2 and a sand-absorbing device 3, and the sand-washing device 2 and the sand-absorbing device 3 are arranged in the cover body 1. The sand device 2 gathers the mud and gravel together, and the sand suction device 3 sucks and discharges the mud and gravel to the outside of the cover body (1), wherein:

[0023] The cover body 1 mainly includes a circular steel casing 11, a sealing plate 12, a limit frame 13 and the like. The steel casing 11 is a hollow cylinder made of steel plates, with no cover at the upper and lower ends; the sealing plate 12 is a circular steel plate with the same inner diameter as the steel casing 11, and the sealing plate 12 is vertically fixed at a distance from the steel casing 11. On the inner wall at a certain distance from the bottom end, a closed sand-absorbing sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com