Bottle cap online cooling system

A technology for cooling systems and bottle caps, which is applied to household components, household appliances, and other household appliances. It can solve problems such as pollution, increasing the difficulty of maintaining the cleanliness of bottle caps on the conveyor line, and occupying a large space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

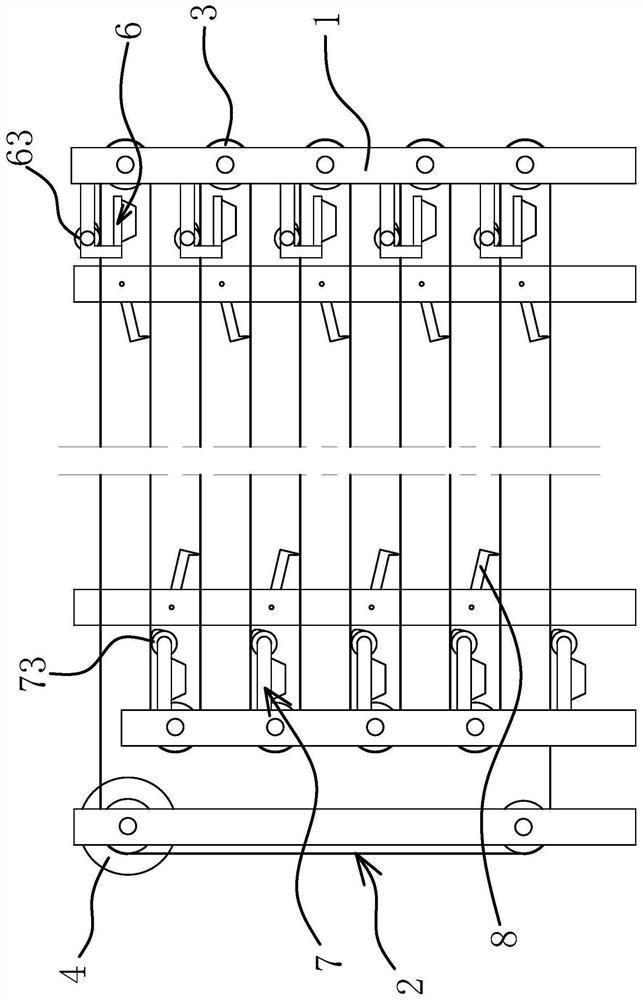

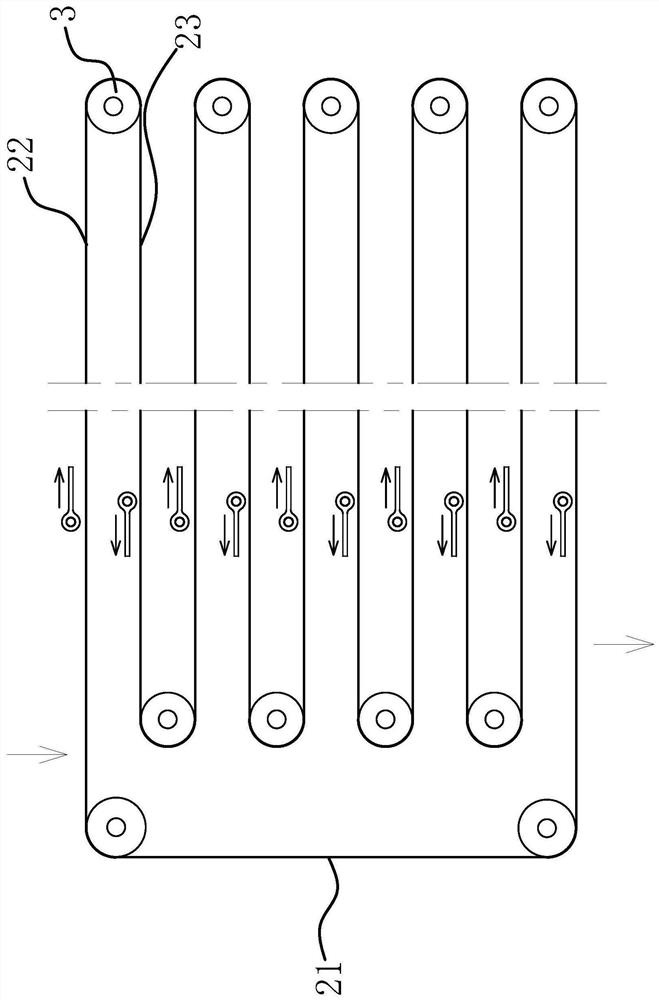

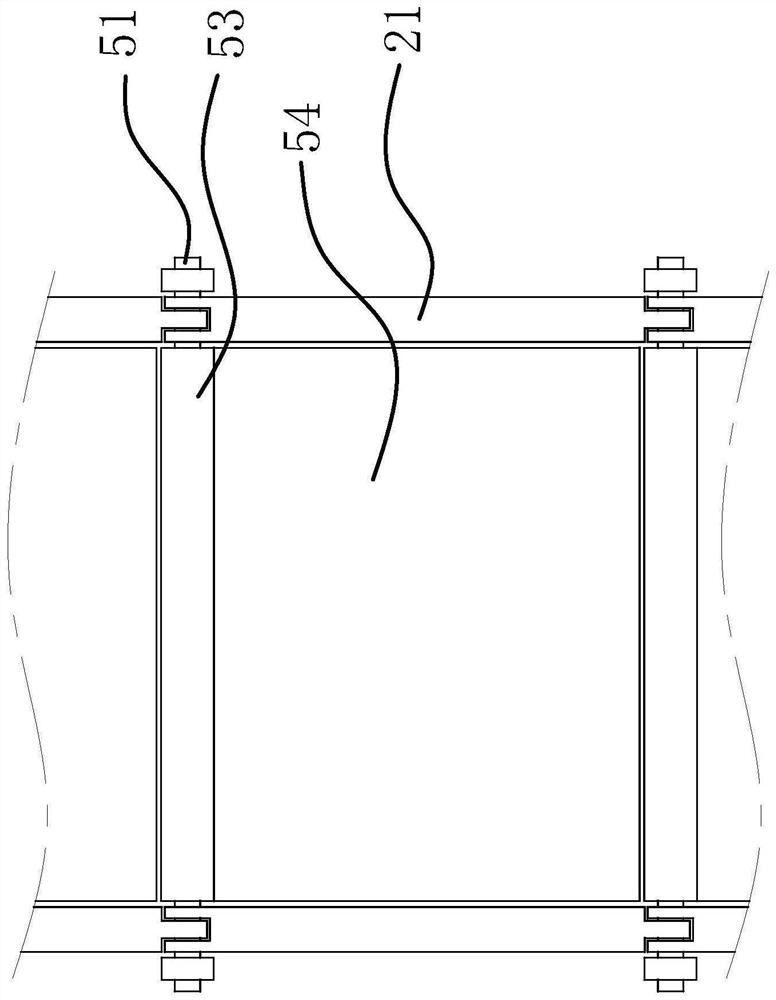

[0022] Such as Figure 1-7 Shown, comprise several runners 3 of frame 1, conveyor belt 2, traction conveyor belt 2, wherein a runner 3 is connected with a drive motor 4, and each runner 3 is connected on the frame 1 in rotation, and conveyor belt 2 includes Vertical uplink section 21, several forward sections 22 and some turn-back sections 23 corresponding to the previous section 22 one by one, the end of the uplink section 21 is connected to the beginning of the topmost forward section 22, and the forward section 22 and Turnback sections 23 are arranged alternately, and the bottom turnback section 23 is connected to the beginning of the uplink section 21. The conveyor belt 2 is composed of several chain links connected en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com