On-orbit calibration method for satellite cold air propulsion system flow sensor

A flow sensor and propulsion system technology, which is applied in the field of on-orbit calibration of flow sensors for satellite air-conditioning propulsion systems, can solve problems such as lack of flow and calibration problems of conversion coefficients of flow sensors, and achieves high calculation accuracy, mature theoretical foundation, and convenient operation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further elaborated below in conjunction with embodiment.

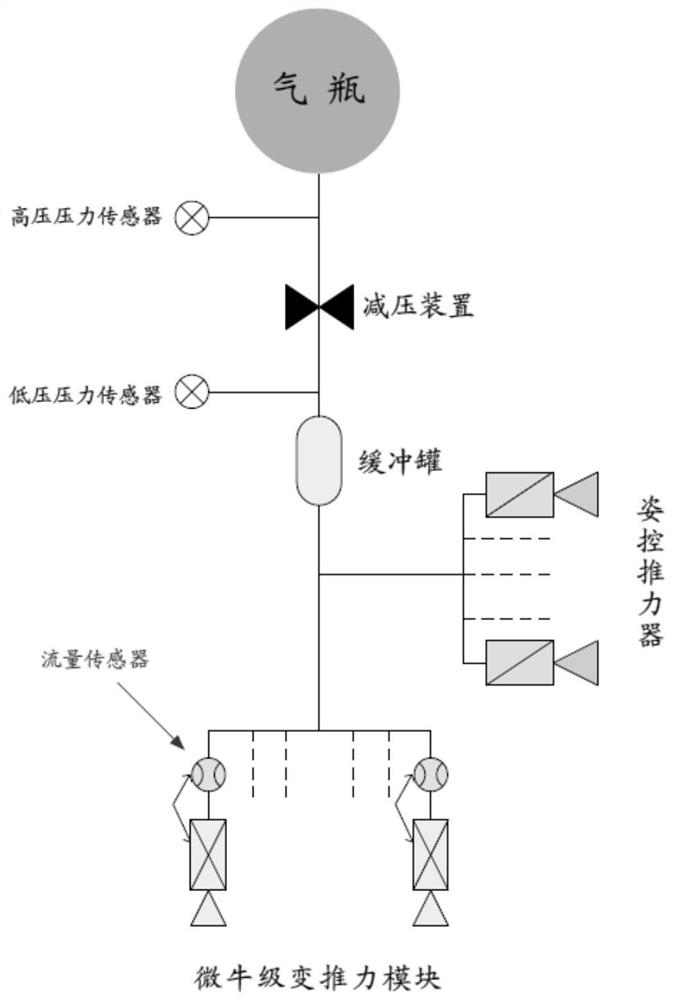

[0041] An on-orbit calibration method for a flow sensor of a satellite cold air propulsion system according to the invention is suitable for a high-precision variable thrust cold air propulsion system. System settings such as figure 1 shown. The system hardware includes high-pressure gas cylinders, high-pressure pressure sensors, decompression devices, low-pressure pressure sensors, buffer tanks, attitude control thrusters (including solenoid valves), micro-new variable thrust modules (including flow sensors), thrust controllers, temperature control Components and supporting pipe valves, etc. Among them, the flow sensor is integrated in the micro-Neutral variable thrust module, and the flow sensor, the micro-Neutral variable thrust module and the variable thrust controller form a closed-loop control system for adjusting the output thrust.

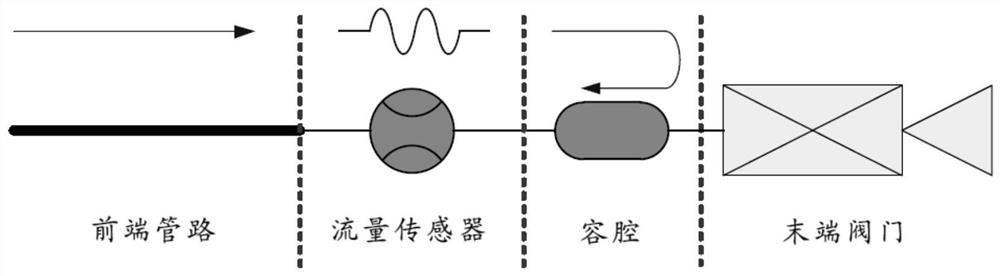

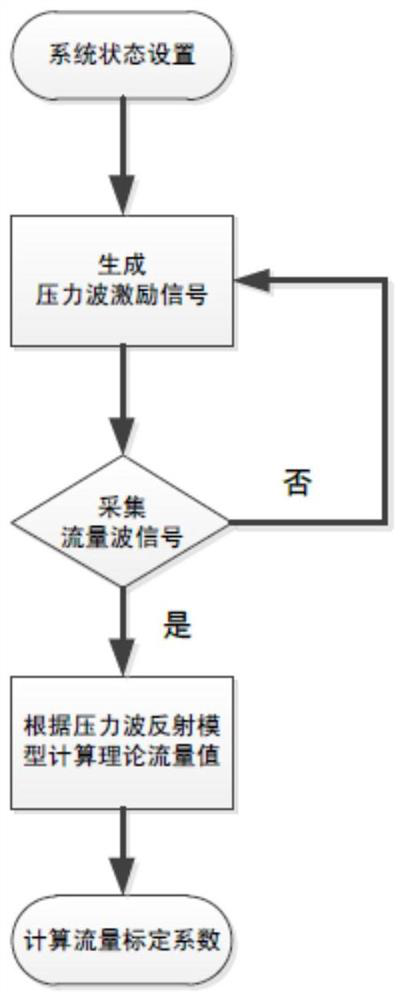

[0042] An on-orbit calibration method f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com