A multi-functional spinner with variable strength and its design method

A design method, multi-functional technology, applied in design optimization/simulation, conveying bulk materials, transportation and packaging, etc., can solve the problems of unbound fluid flow characteristics, low swirl intensity, difficult and coarse particle hydraulic lifting, etc., to achieve structural Easy and fast disassembly and assembly, good sealing, and the effect of reducing the risk of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

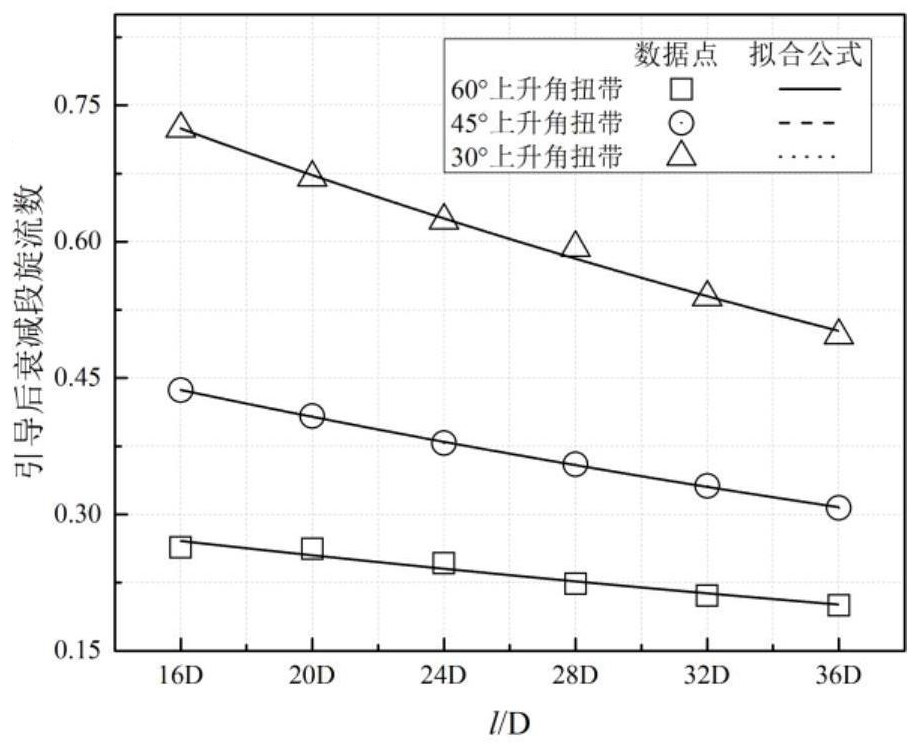

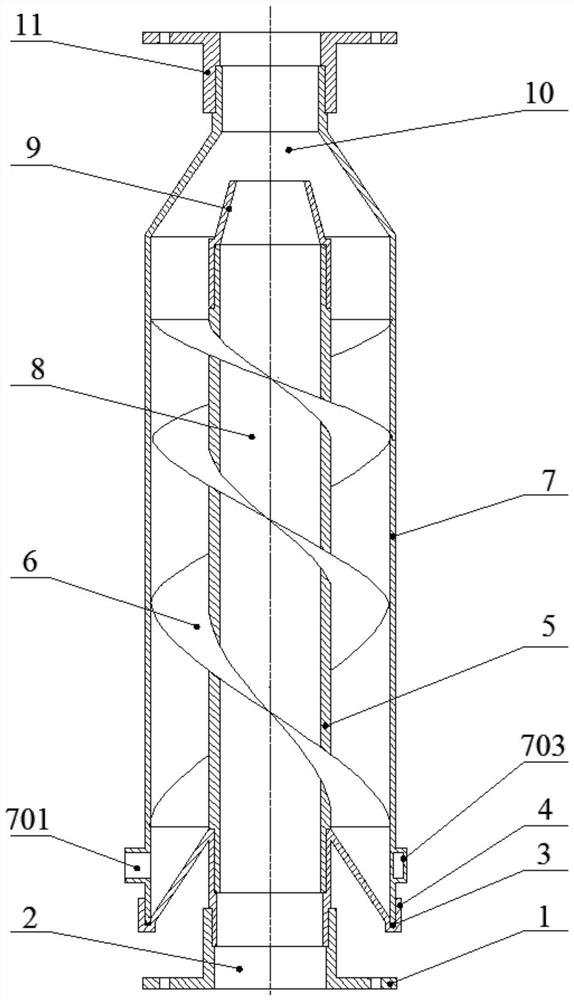

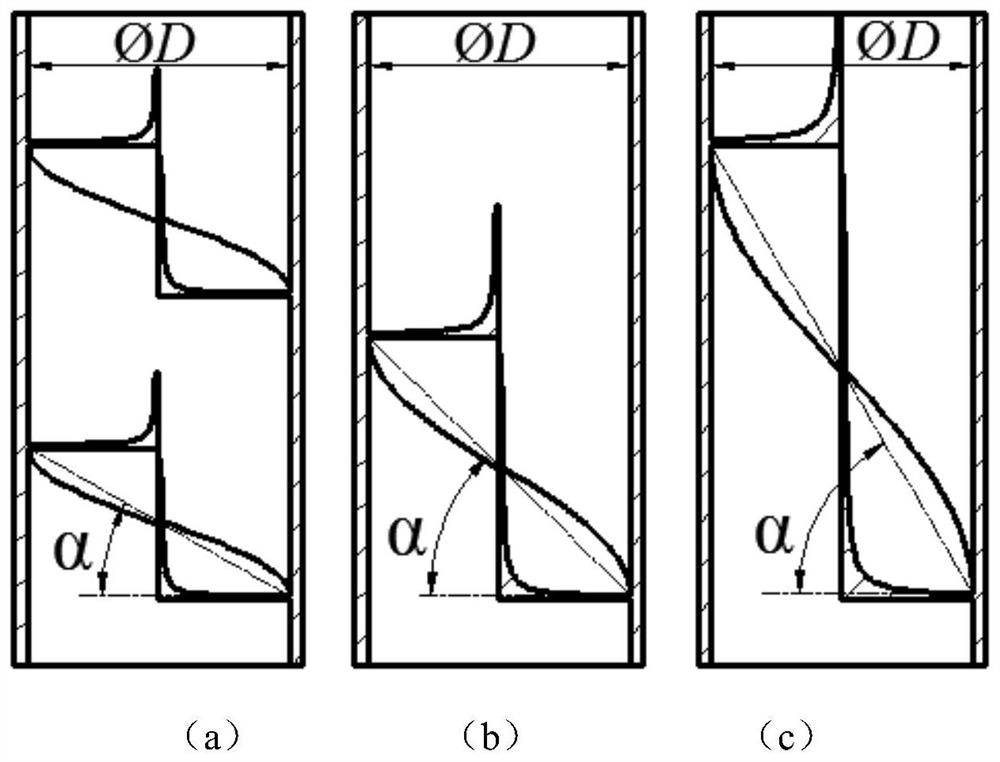

[0061] Such as Figure 1-Figure 5 As shown, a multi-function spinner with multi-port variable strength of the present invention includes a multi-port housing 7, the multi-port housing 7 is provided with a cone at the upper end, and a multi-threaded bottom cover with an opening is sealingly connected to the lower end. 4, the multi-port housing 7 is provided with an inner flow pipe 5 communicating with the multi-threaded bottom cover 4, and at least one head is fixedly arranged on the outer wall of the inner flow pipe 5 along the axial direction. The variable lift angle twist belt 6, the upper end of the inner flow pipe 5 is connected with a conical guide sleeve 9, the upper end cone of the multi-port housing 7 is provided with a cylindrical port with external threads, and the cylindrical port is threaded with a The second flange 11 constitutes the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com