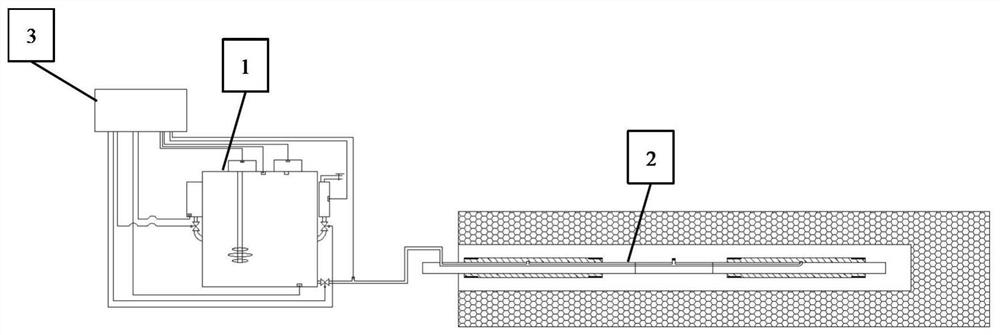

Full-automatic dynamic hole sealing system

A fully automatic and dynamic technology, applied in safety devices, sealing/seal, gas discharge, etc., can solve the problems of cumbersome manual operation and poor sealing effect, achieve strong interaction, good sealing, and reduce construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The specific workflow in this implementation is:

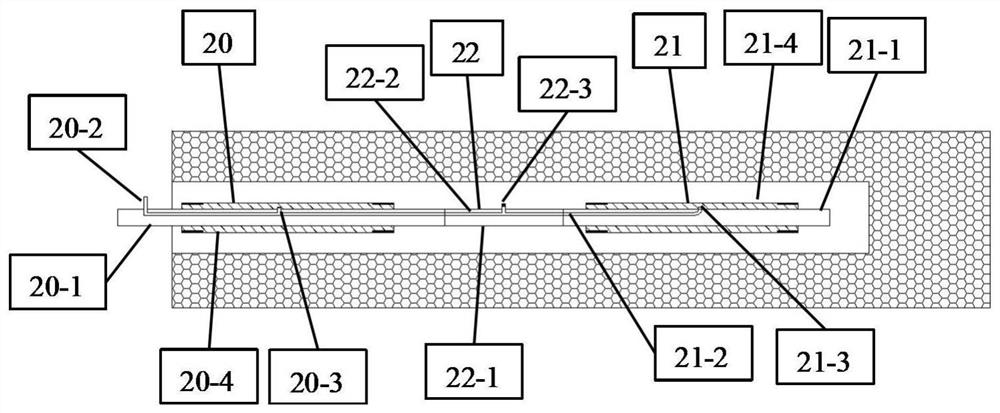

[0056] Connect the adaptive dynamic hole sealer 2 and send it into the borehole, connect the grout outlet 15 of the automatic batching and grouting device 1 with the first grouting pipe 20-1, and connect the water supply pipeline 14-3 to the mine’s water supply On the line, energize the system.

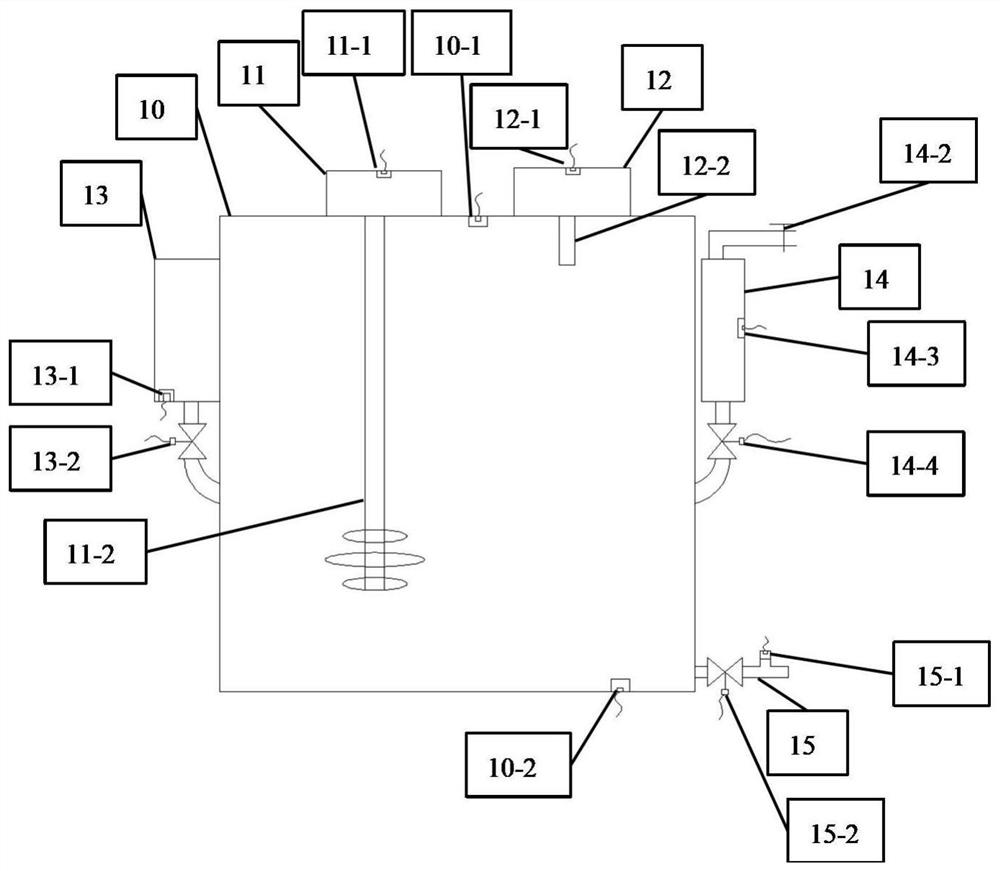

[0057] At the beginning of grouting, the third pressure sensor 15-1 detects that there is no pressure in the self-adaptive dynamic sealer in the borehole, and the grouting operation needs to be carried out, and the hydraulic pressure sensor 10-2 detects that there is not enough grout in the tank, and the grouting operation needs to be carried out. Slurry replenishment, therefore by opening the first solenoid valve 13-2 and the second solenoid valve 14-2 to perform the replenishment and water replenishment operations, and through the second pressure sensor 13-1 and the electromagnetic flowmeter 14-1 to judge the amount of raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com