Spiral curved surface wear prediction method

A technology of helical surface and prediction method, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve the problems of inaccurate calculation of roller screws, and achieve the effect of short research cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0034] The invention provides a method for predicting wear of a spiral surface. During the operation of a roller screw, the wear of the spiral surface is predicted based on the Archard wear prediction method, which specifically includes the following steps:

[0035] Step 1. Establish the required coordinate system and the conversion relationship between the coordinate systems;

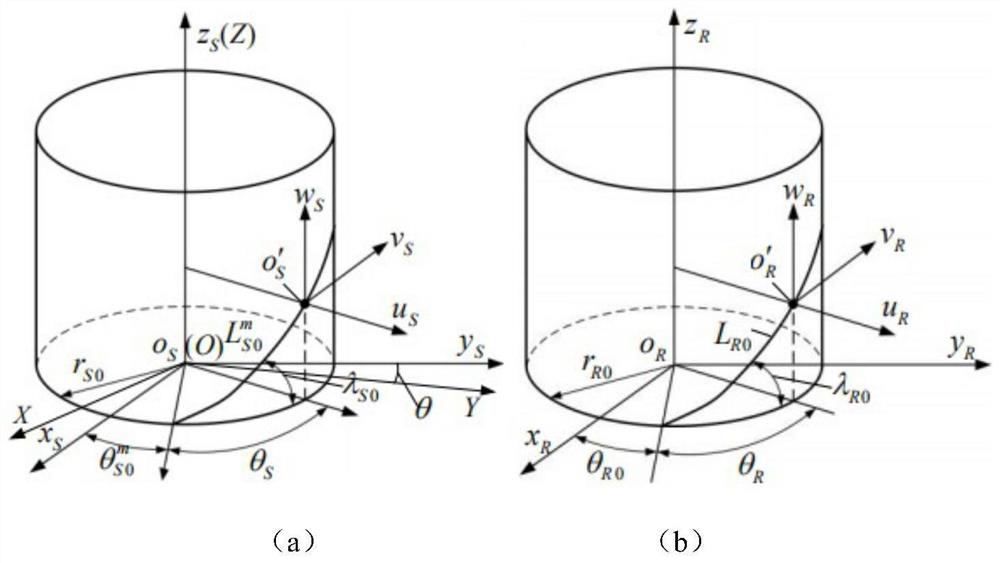

[0036] In this embodiment, the coordinate system in step 1 includes the global coordinate system, the screw fixed coordinate system, the screw section coordinate system, the roller fixed coordinate system, and the roller section coordinate system, such as figure 1 shown, and adopt the method of coordinate transformation to obtain the conversion relationship between the coordinate systems;

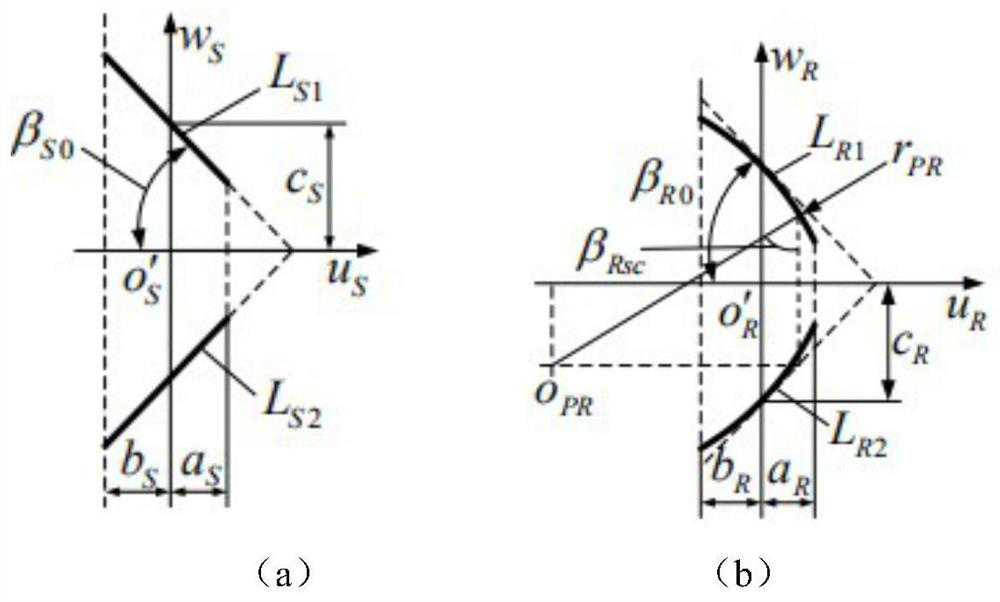

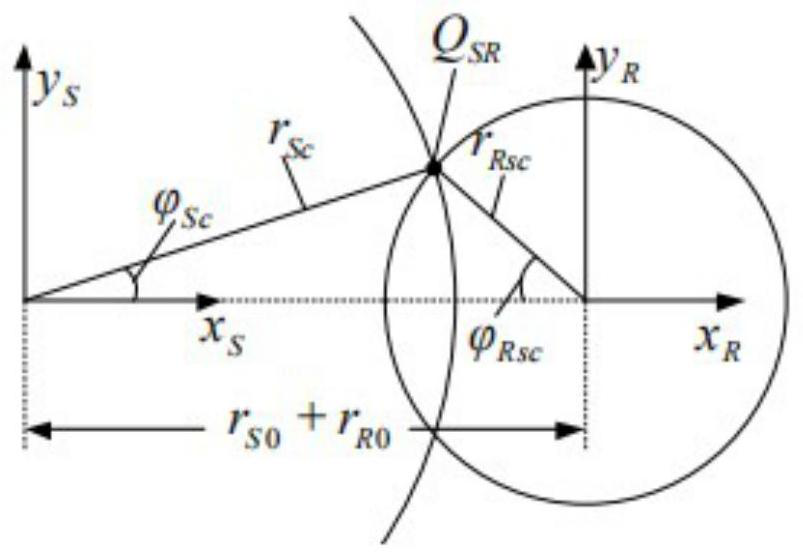

[0037] Step 2, establishing the surface equation of the screw and the roller helical surface;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com