Self-locking segmentation design method for maxilla defect prosthesis

A prosthetic and self-locking technology, applied in bone implants, metal processing equipment, 3D printing, etc., can solve the problems of prolonging the recovery of oral dysfunction, affecting the effect of bone defect repair and restoration of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] 1. According to the difference in the shape of the maxillary defect in different patients, on the premise of ensuring the smooth implantation of the prosthesis during the operation, divide the prosthesis into 2-6 pieces.

[0010] 2. The segmentation principle is to ensure that the outer edge of the restoration can be smoothly aligned with the shape of the patient's defect edge, and the segmentation plane is located near the surgical incision to avoid segmentation in the concave part of the restoration.

[0011] 3. The curvature of each part on the surface of the restoration is consistent with the corresponding curvature of the maxilla in the patient's healthy state.

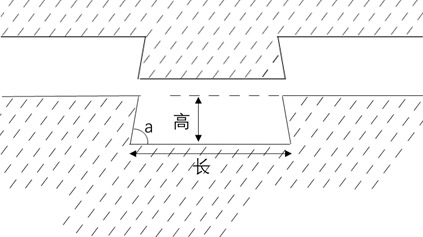

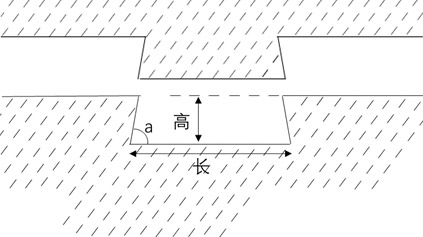

[0012] 4. If figure 1 As shown in Fig. 1, a "falcon" or "Ω" type partition design is adopted between two adjacent restorations.

[0013] 5. There is a groove-shaped design on the contact surface of the two partition blocks of the restoration, and the inclination angle of each raised part with the bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com