Detection equipment for intelligent manufacturing

A technology of intelligent manufacturing and testing equipment, applied in sorting and other directions, can solve the problems of low efficiency of bottle cap air tightness detection, low bottle cap turnover efficiency, low detection accuracy, etc., to achieve high practicability and universality, The effect of convenient subsequent recycling and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

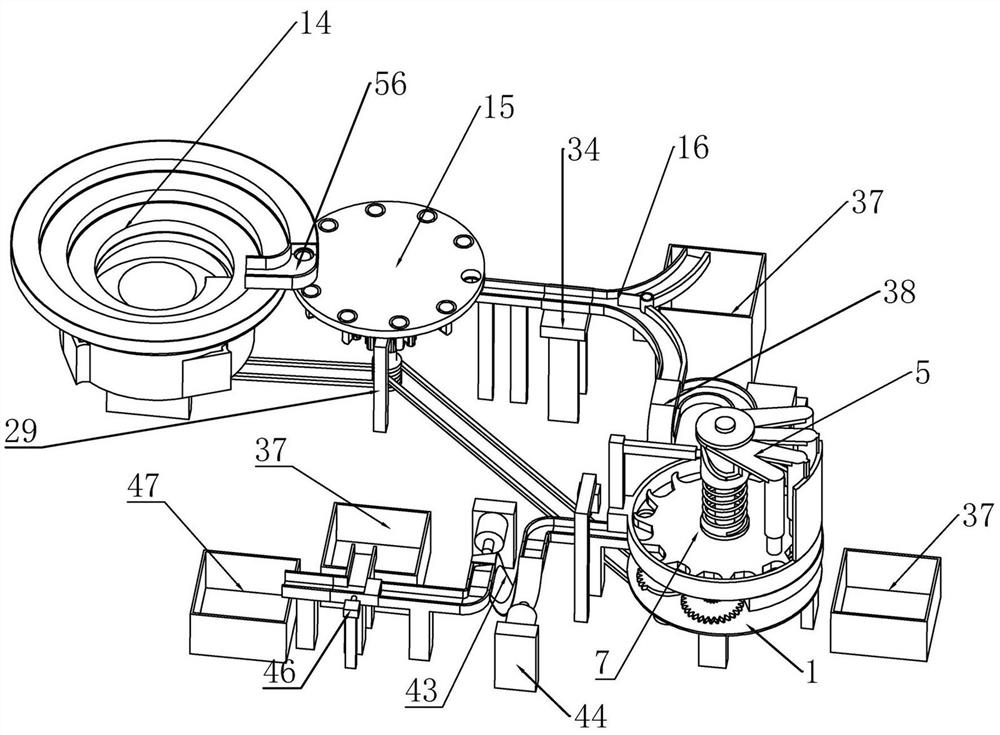

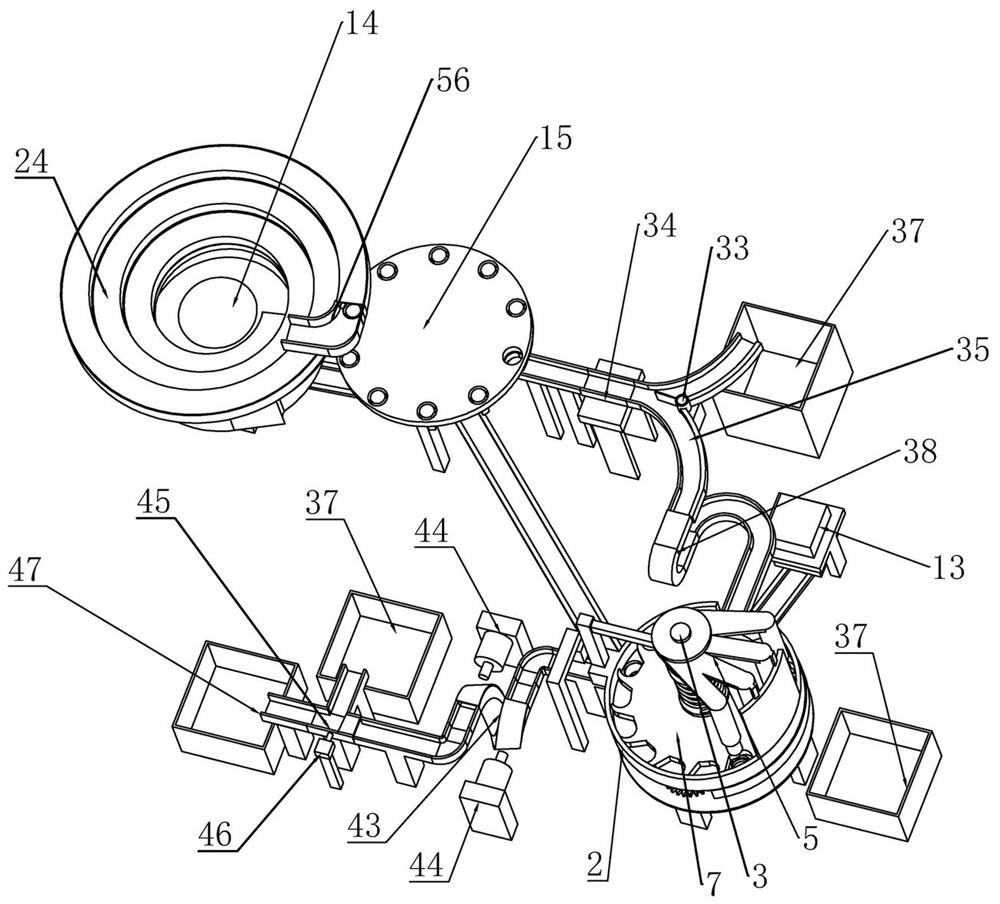

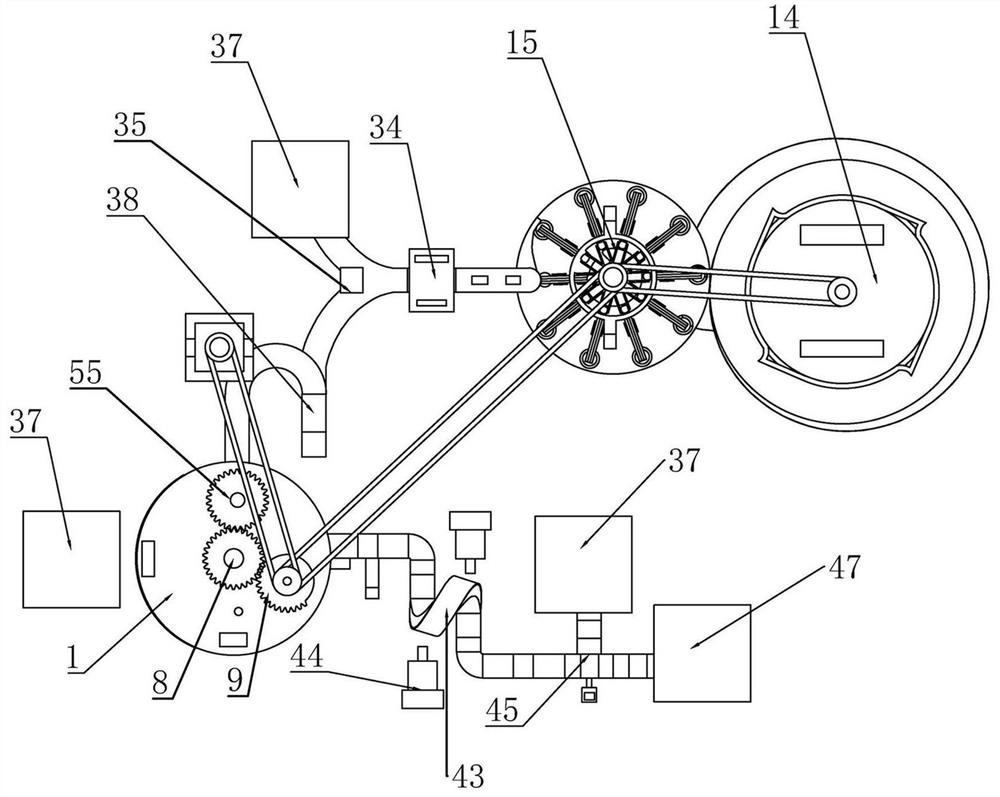

[0051] Embodiment 1, the present invention is a detection device for intelligent manufacturing, including a support plate 1, the support plate 1 is fixed on the ground, and the feature is that an airtight rotary groove 2 is coaxially and fixedly connected above the support plate 1 , the airtight rotary groove 2 and the fixed disk 3 are connected by a connecting beam, so that neither the support plate 1 nor the airtight rotary groove 2 can rotate, and the airtight rotary groove 2 is coaxially connected with an airtight lifting shaft 3 , the airtight lifting shaft 3 runs through the support plate 1 and the airtight rotary groove 2, and one end of the airtight lifting shaft 3 is coaxially rotated and connected with a space lifting cylindrical cam 4, which can ensure that when the airtight lifting shaft 3 rotates, it can drive the space lifting Cylindrical cam 4 rotates, by setting vertical positioning pin and positioning pin chute between airtight lifting shaft 3 and space lifting...

Embodiment 2

[0059] Embodiment 2, on the basis of Embodiment 1, the described feeding conveying structure comprises a feeding base 14 arranged in sequence on one side of the support plate 1, a screening tray 15 and a feeding guide rail 16, and the feeding base 14 Fixed on the ground, the feeding base 14 is fixedly connected with a feeding tray 17, the feeding tray 17 is composed of an outer spiral guide groove, the cross section of the guide groove is a rectangular ring, and the bottle cap can lie horizontally Through the guide groove, when the bottle cap is vertical, the bottle cap will not enter the guide groove, and the guide groove is set as an external spiral, which can ensure that the screening disc 15 can be in contact with the lower surface of the upper end of the guide groove, and can be conveniently transported to The bottle cap at the top of the guide groove is transported out after passing through the screening disc 15. The lower end surface of the feeding disc 17 is coaxially c...

Embodiment 3

[0061] Embodiment three, on the basis of embodiment two, the outer spiral guide groove 24 is provided on the described feeding tray 17, the height of the outer spiral guide groove 24 is slightly higher than the height of the bottle cap but less than the diameter of the bottle cap, so that The bottle cap can only lie flat and enter the outer spiral guide groove 24, and not enter vertically. The top of the outer spiral guide groove 24 has a feeding screening port 25, and the size of the feeding screening port 25 and the bottle cap The size of the feeding tray 17 is consistent, the side of the feeding tray 17 is provided with a screening tray 15, and the screening tray 15 is in contact with the lower end surface of the feeding screening port 25, and the screening tray 15 is provided with several and feeding screening ports 25 The blanking screening port 27 with the same size, the described loading screening port 25 and the described blanking screening port 27 are through-connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com