Airtightness detection equipment for power battery module

A power battery and airtight detection technology, which is applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, measuring device, etc. It can solve problems such as unsuitable for industrial application scenarios, complicated operation, and low precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. The following embodiments are provided by way of illustration in order to fully convey the spirit of the present invention to those skilled in the art to which the present invention pertains. Therefore, the present invention is not limited to the embodiments disclosed herein.

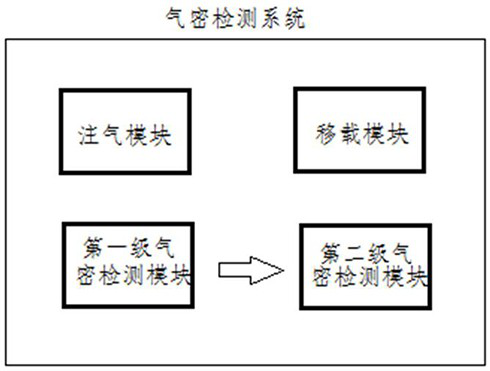

[0035] The present invention proposes a power battery module airtight detection device, which includes a gas injection module, a transfer module, a first-level airtight detection module and a second-level airtight detection module, such as figure 1 shown.

[0036] The gas injection module is used for injecting compressed air with a first temperature into the power battery module. In the present invention, the first temperature may be any temperature lower than room temperature, preferably 20 degrees Celsius or more lower than room temperature.

[0037] The power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com