Automatic roller replacing unit for rail-changing type lithium battery diaphragm and method for realizing automatic roller changing based on automatic roller replacing unit for rail-changing type lithium battery diaphragm

A lithium battery separator, automatic technology, applied in the direction of winding strip, thin material processing, transportation and packaging, can solve the problems of inconvenient automatic recycling of material rollers, low efficiency of manual replacement, etc., to reduce labor intensity and improve replacement. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

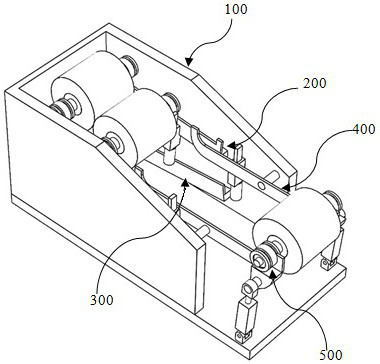

[0036] like figure 1 As shown, a track-changing lithium battery diaphragm automatic roll changing unit includes a stand 100, a first set of fixed guide rails 200 for automatic feeding of lithium battery diaphragm material rolls, and a second set of fixed guide rails for automatic recovery of lithium battery diaphragm material rolls. The combined fixed guide rail 300, the combined swing guide rail 400 for automatically switching the first combined fixed guide rail 200 and the second combined fixed guide rail 300, and the material roller assembly 500 for carrying the lithium battery separator.

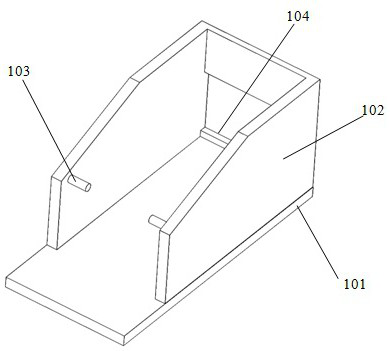

[0037] like figure 2 As shown, the stand 100 includes a rectangular bottom plate 101, and a U-shaped side wall plate 102 installed vertically on the edge of the rectangular bottom plate 101. The bottom of the short side wall of the U-shaped side wall plate 102 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com