Cable coiling machine

A cable and wire take-up reel technology, which is applied in the field of cable take-up machines, to achieve the effects of neatly coiled products, guaranteed packaging quality, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

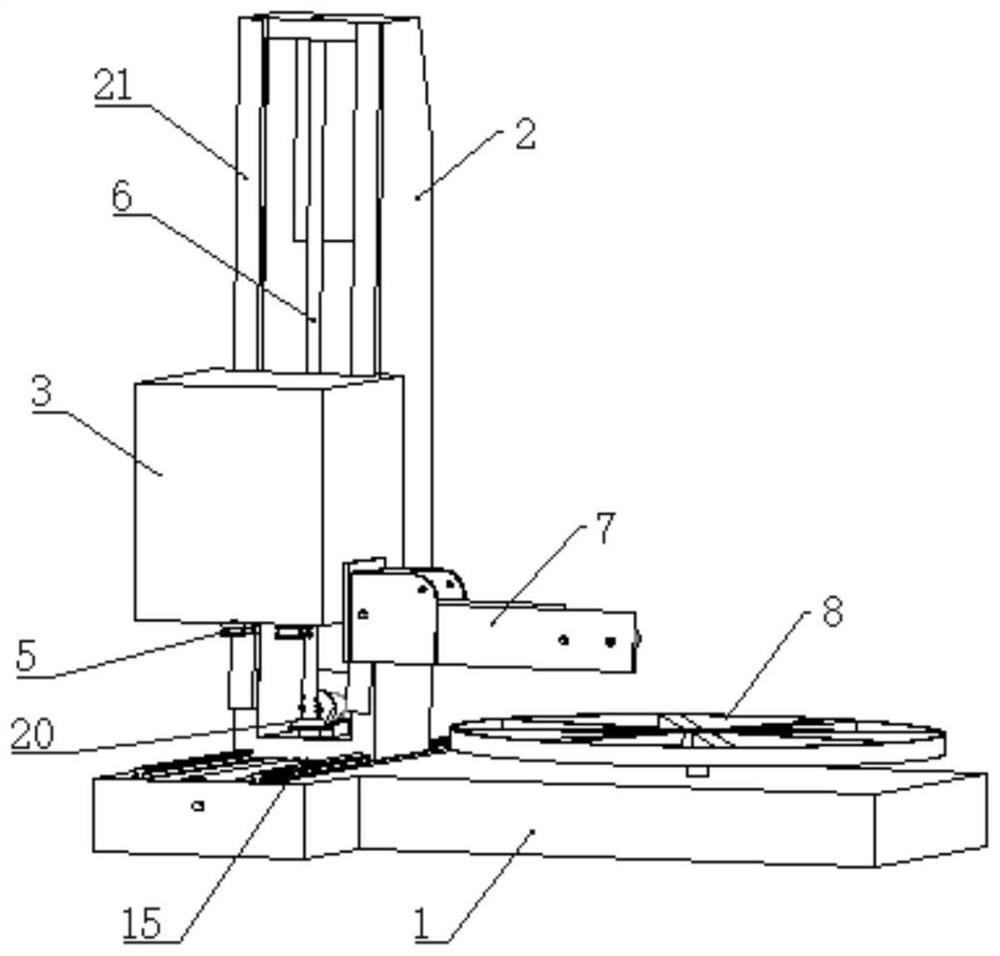

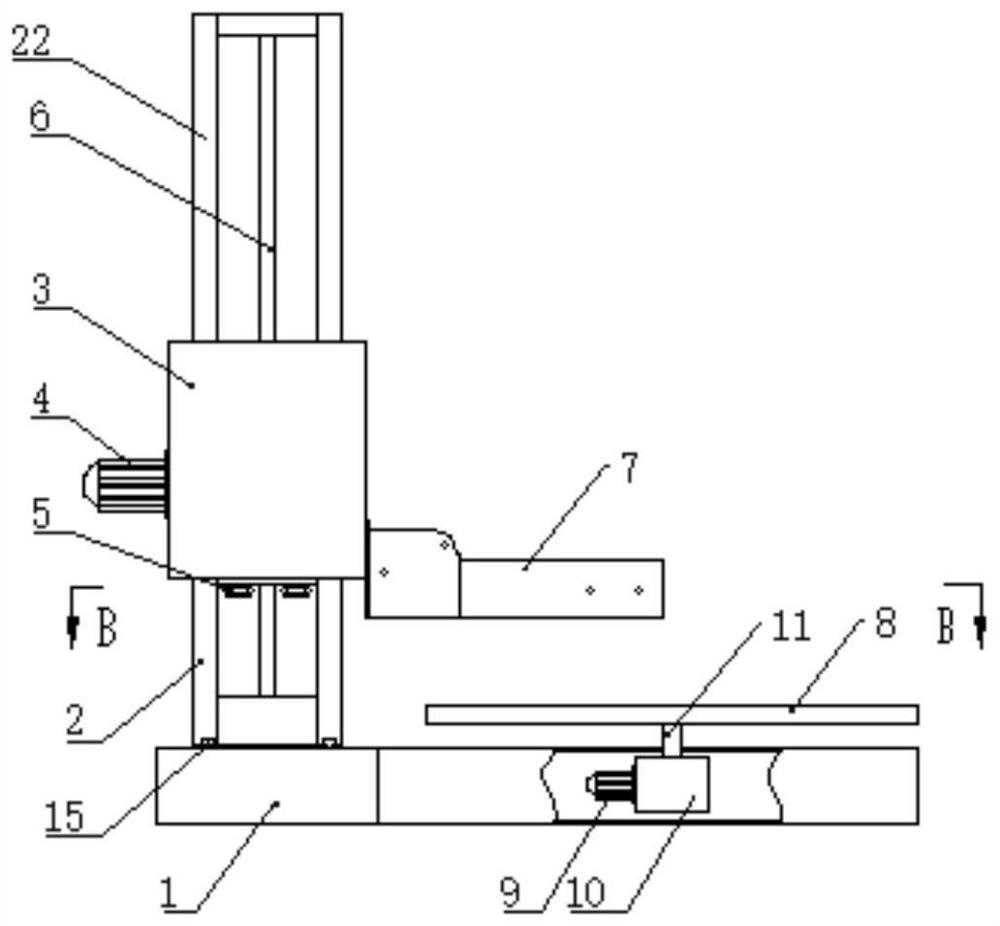

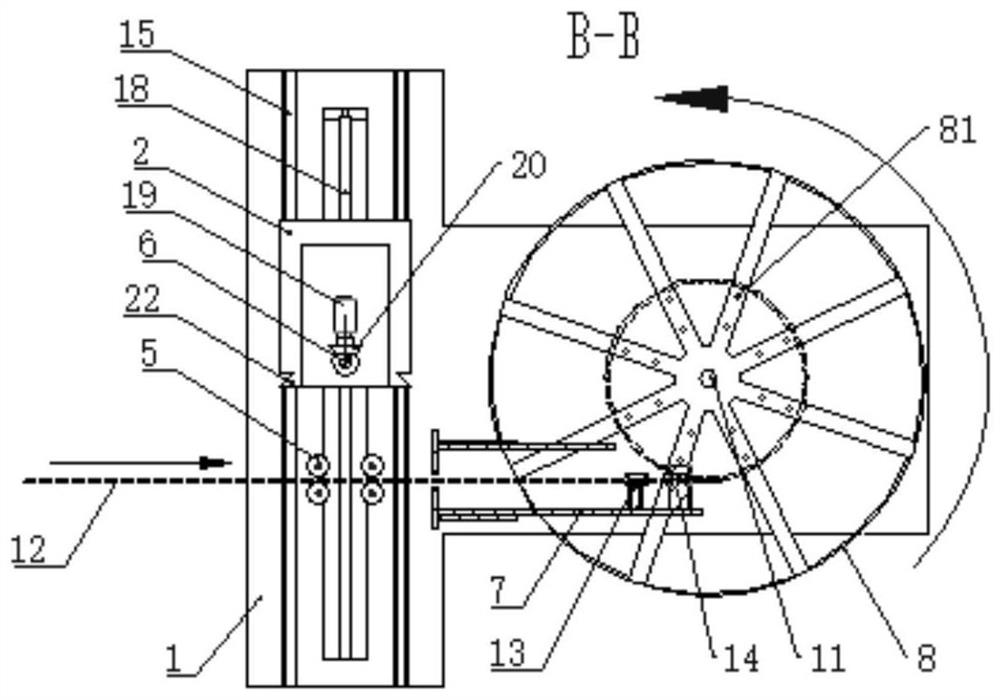

[0016] see Figure 1-Figure 6 , a cable winding machine of the present invention is characterized in that it includes a base 1, a stand 2, a lifting slider 3, a conveying frame 7 and a take-up reel 8, and the bottom end of the stand 2 is slidably connected to the base 1 on the translation guide rail 15 of the stand, and is connected with the transmission of the stand translation drive device; on the base 1 next to the stand 2, the take-up reel 8 is rotated and installed, and the shaft 11 of the take-up reel 8 is connected with the take-up line installed in the base The disk drive device is connected by transmission; the stand 2 is provided with a lifting guide rail 22; the lifting slider 3 is slidably installed on the lifting guide rail 22, and is connected with the slider lifting drive device; At least one pair of feeding wheels 5 (this embodiment is provided with two pairs of feeding wheels 5, and the cable 12 passes in the arc-shaped concave ring between each pair of feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com