Floating oil absorption system for sewage treatment

A technology for sewage treatment and absorption system, which is used in grease/oily substance/float removal devices, liquid separation, chemical instruments and methods, etc. It can solve the problems of low absorption efficiency and inability to absorb, and achieve simple structure and oil slick absorption. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] The content of this embodiment includes two parts, the structural part and the working principle.

[0032] Structural part:

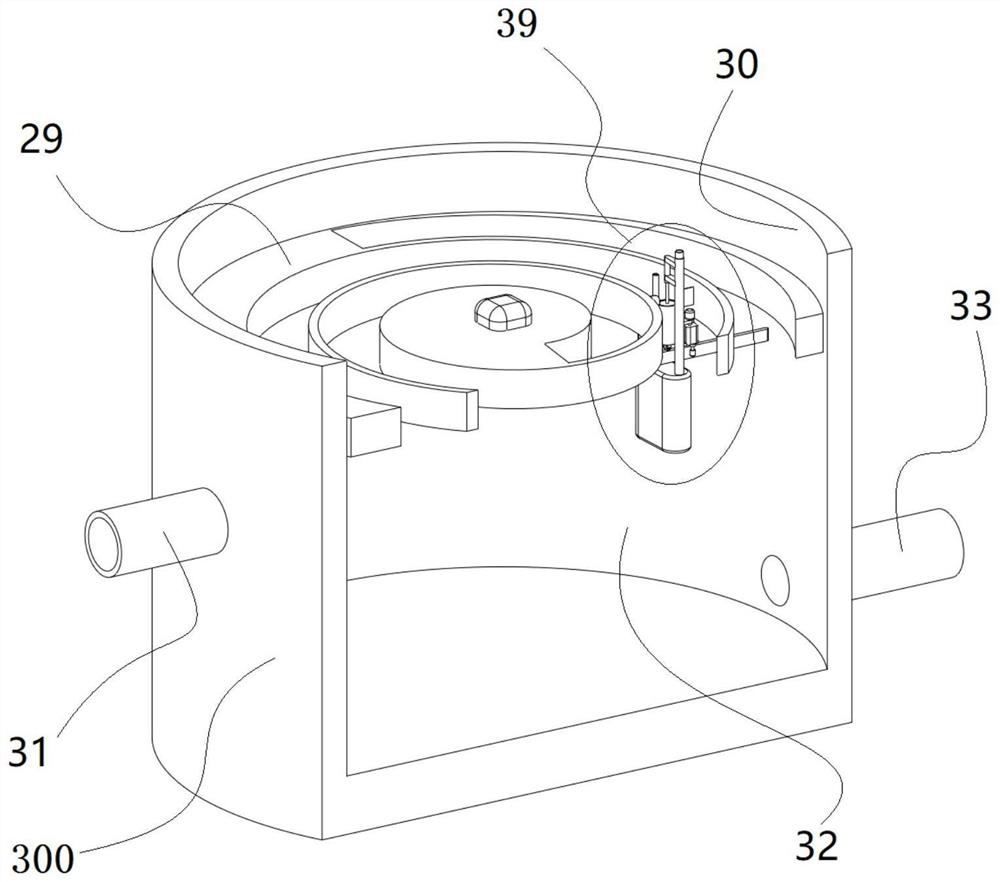

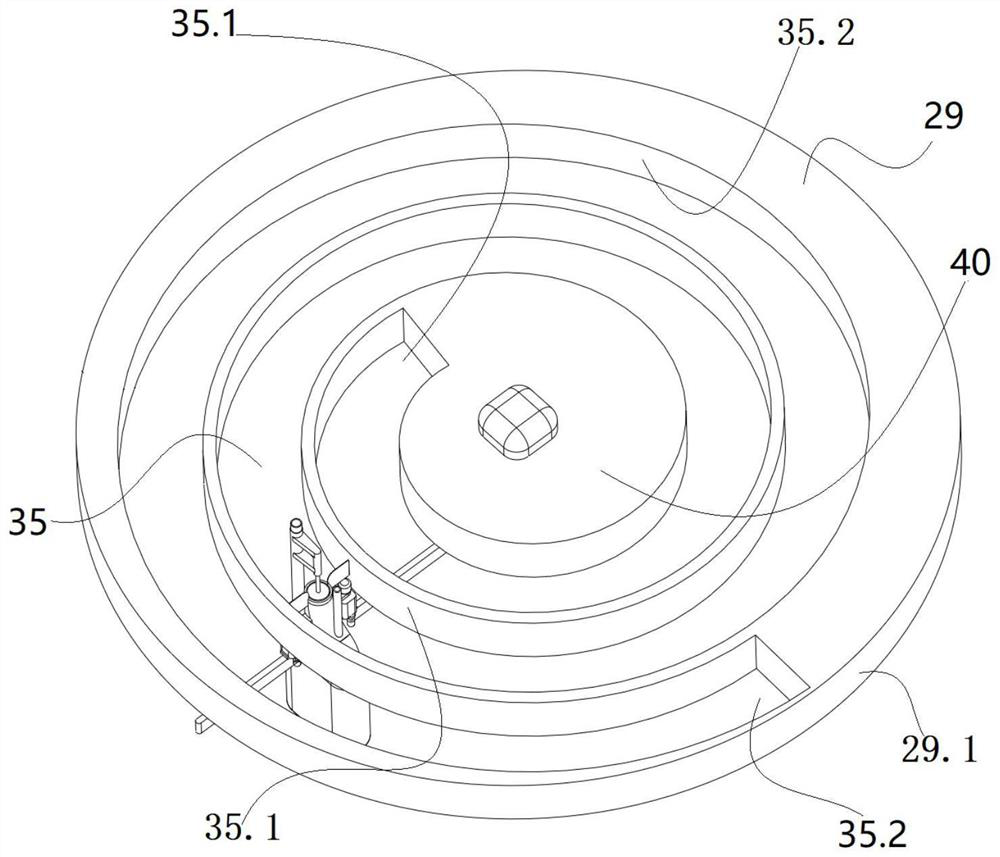

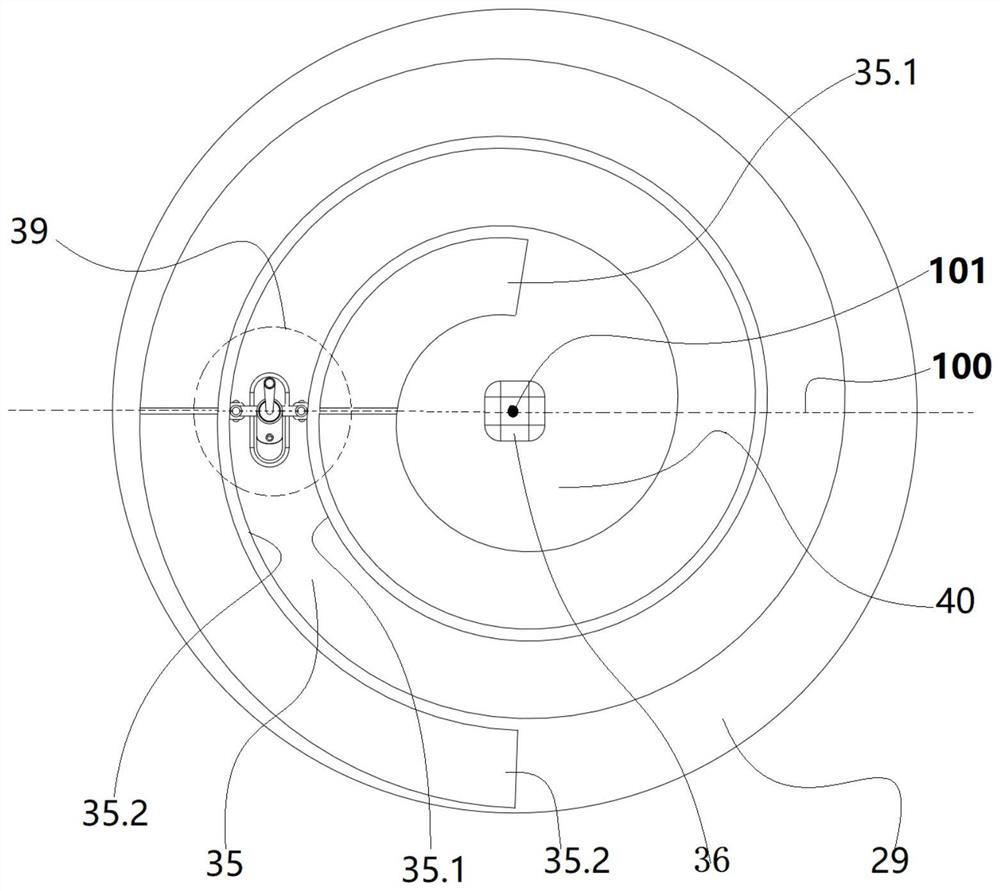

[0033] as attached Figures 1 to 9 The shown oil slick absorption system for sewage treatment includes a columnar oil slick absorption tower 300, a cylindrical oil slick absorption pool 32 inside the oil slick absorption tower 300, and a sewage inlet pipe 31 and a sewage outlet pipe 33 , the outlet of the sewage inlet pipe 31 is connected to the oil slick absorption pool 32, and the inlet of the sewage outlet pipe 33 is connected to the oil slick absorption pool 32;

[0034] A disc-shaped float 29 is arranged coaxially in the said oil slick absorbing tank 32, and the float outer ring 29.1 of said disc-shaped float 29 is in clearance fit with the cylinder inner wall 30 of said oil slick absorbing tower 300, said Disc-shaped float 29 ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com