Harmful waste gas treatment equipment and treatment method

A technology for waste gas treatment and treatment method, applied in the field of harmful waste gas treatment equipment, can solve the problems of few organic waste gas and acidic waste gas purification methods, the inability to accurately predict the temperature and humidity relationship of waste gas, and the inability to detect various harmful gases, etc. Accurate monitoring of installation, outstanding absorption effect, and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

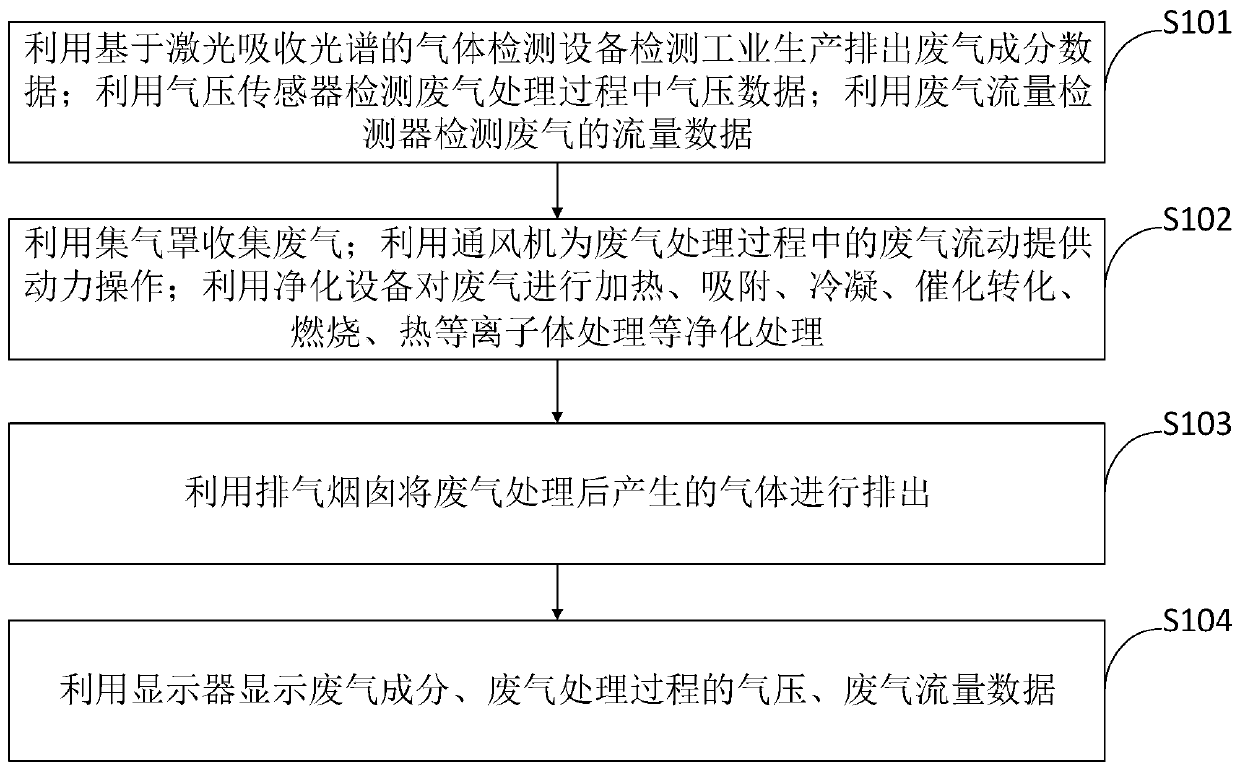

[0060] In order to further understand the invention content, features and effects of the present invention, the following embodiments are exemplified, and detailed descriptions are included with the accompanying drawings.

[0061] In the existing waste gas treatment process, the detection equipment for the waste gas flow consumes a lot of power, the measurement accuracy is low, and the range is narrow; at the same time, there are many existing researches on the removal of organic waste gas, but the purification method that can simultaneously remove organic waste gas and acid waste gas less. The detection accuracy of the existing harmful waste gas is not high, and at the same time, the speed is slow; it is impossible to detect a variety of harmful gases.

[0062] In order to solve the above problems, the structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

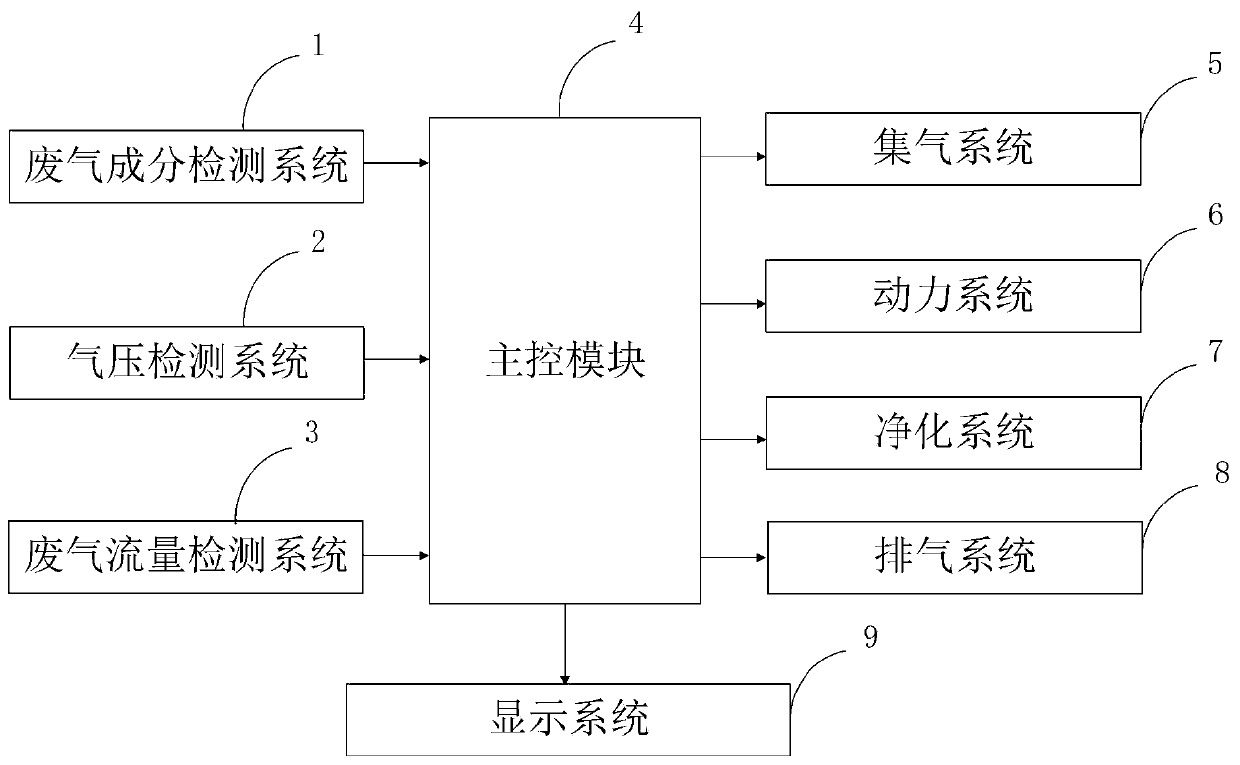

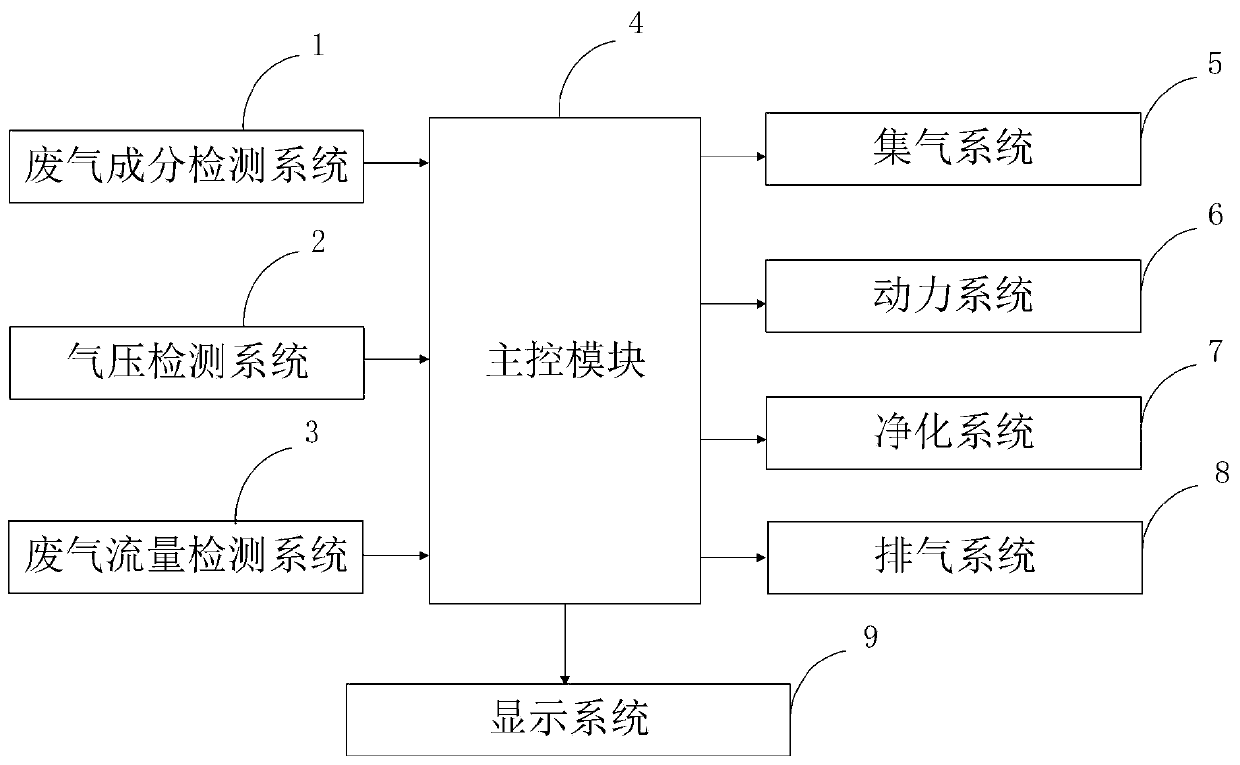

[0063] Such as figure 1 As shown, the harmful exhaust ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com