A carbon source for wastewater denitrification

A carbon source and denitrification technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, special compound water treatment, etc. Too high, high processing efficiency, and the effect of improving specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

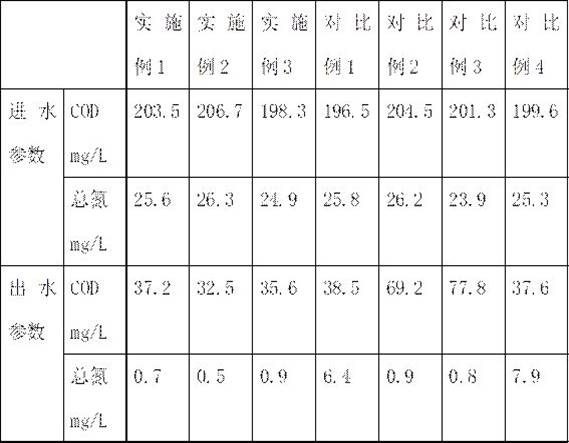

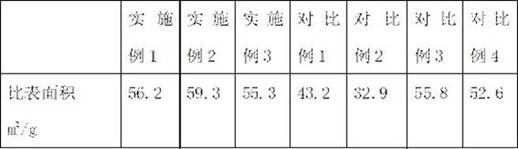

Examples

Embodiment 1

[0029] In Example 1, a carbon source for sewage denitrification mainly consists of the following components by weight: 25 parts of glucose, 15 parts of maltose, 10 parts of polysaccharide, 10 parts of mango peel, 10 parts of coconut meat, coconut shell 30 parts of extract, 3 parts of titanium dioxide, 10 parts of calcium hydroxide, 50 parts of montmorillonite and 5 parts of polyacrylamide;

[0030] The preparation method of described carbon source, comprises the following steps:

[0031] S1. First add deionized water three times the volume of montmorillonite to montmorillonite, add polyacrylamide, then add titanium tetrachloride solution, stir slowly, and slowly add calcium hydroxide powder under the condition of 30°C, and wait for the solution When the pH value of the solution rises to 6-7, heat up to 85°C, add the remaining calcium hydroxide powder, continue stirring for 1 hour, and complete the stirring;

[0032] S2. After the stirring is completed, filter while it is hot,...

Embodiment 2

[0046] In Example 2, a carbon source for sewage denitrification mainly consists of the following components by weight: 35 parts of glucose, 25 parts of maltose, 20 parts of polysaccharide, 15 parts of mango peel, 15 parts of coconut meat, coconut shell 50 parts of extract, 6 parts of titanium dioxide, 20 parts of calcium hydroxide, 80 parts of montmorillonite and 10 parts of polyacrylamide;

[0047] The preparation method of described carbon source, comprises the following steps:

[0048]S1. First add deionized water six times the volume of montmorillonite to montmorillonite, add polyacrylamide, then add titanium tetrachloride solution, stir slowly, and slowly add calcium hydroxide powder under the condition of 30°C, and wait for the solution When the pH value of the solution rises to 6-7, heat up to 90°C, add the remaining calcium hydroxide powder, continue stirring for 1 hour, and complete the stirring;

[0049] S2. After the stirring is completed, filter while it is hot, a...

Embodiment 3

[0063] In Example 3, a carbon source for sewage denitrification mainly consists of the following components by weight: 30 parts of glucose, 20 parts of maltose, 15 parts of polysaccharide, 12 parts of mango peel, 12 parts of coconut meat, coconut shell 40 parts of extract, 4 parts of titanium dioxide, 15 parts of calcium hydroxide, 60 parts of montmorillonite and 7 parts of polyacrylamide;

[0064] The preparation method of described carbon source, comprises the following steps:

[0065] S1. First add deionized water 5 times the volume of montmorillonite to montmorillonite, add polyacrylamide, then add titanium tetrachloride solution, stir slowly, and slowly add calcium hydroxide powder under the condition of 30°C, and wait for the solution When the pH value of the solution rises to 6-7, the temperature is raised to 88°C, the remaining calcium hydroxide powder is added, and the stirring is continued for 1 hour until the stirring is completed;

[0066] S2. After the stirring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com