A kind of preparation method of oligosiloxane composite proton exchange membrane containing azole ring

A technology of oligosiloxane and proton exchange membrane, which is applied in the field of preparation of nanocomposite membranes, and can solve the problems of decreased proton conductivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

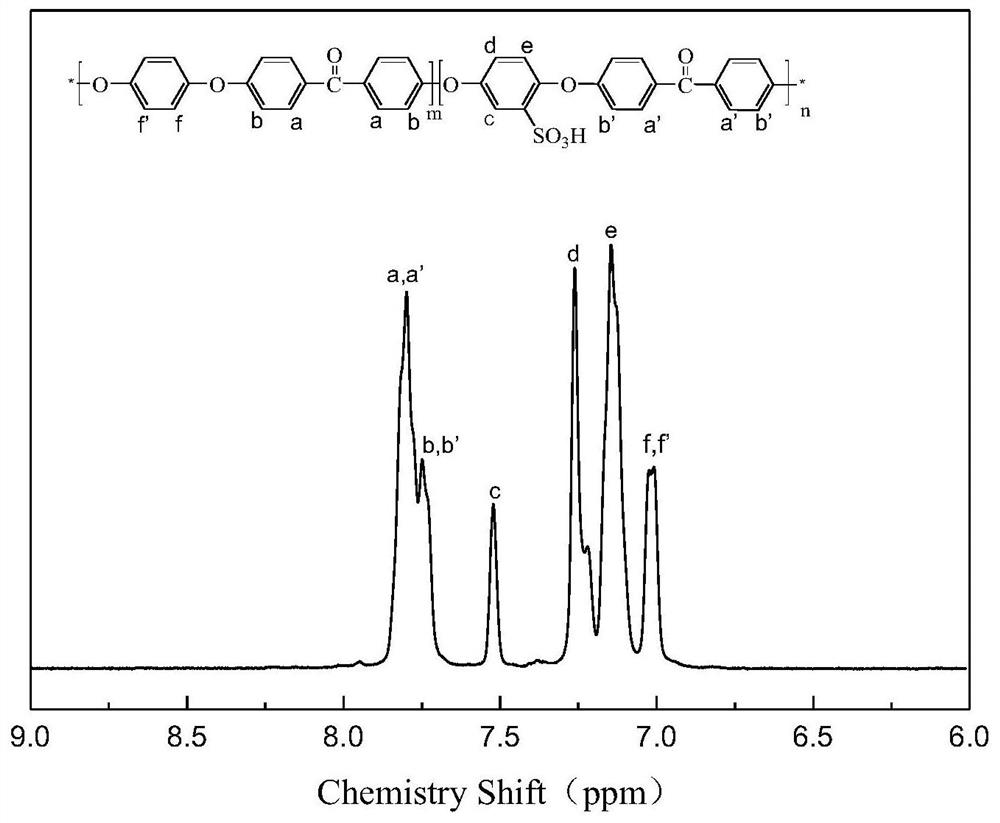

Method used

Image

Examples

Embodiment 1

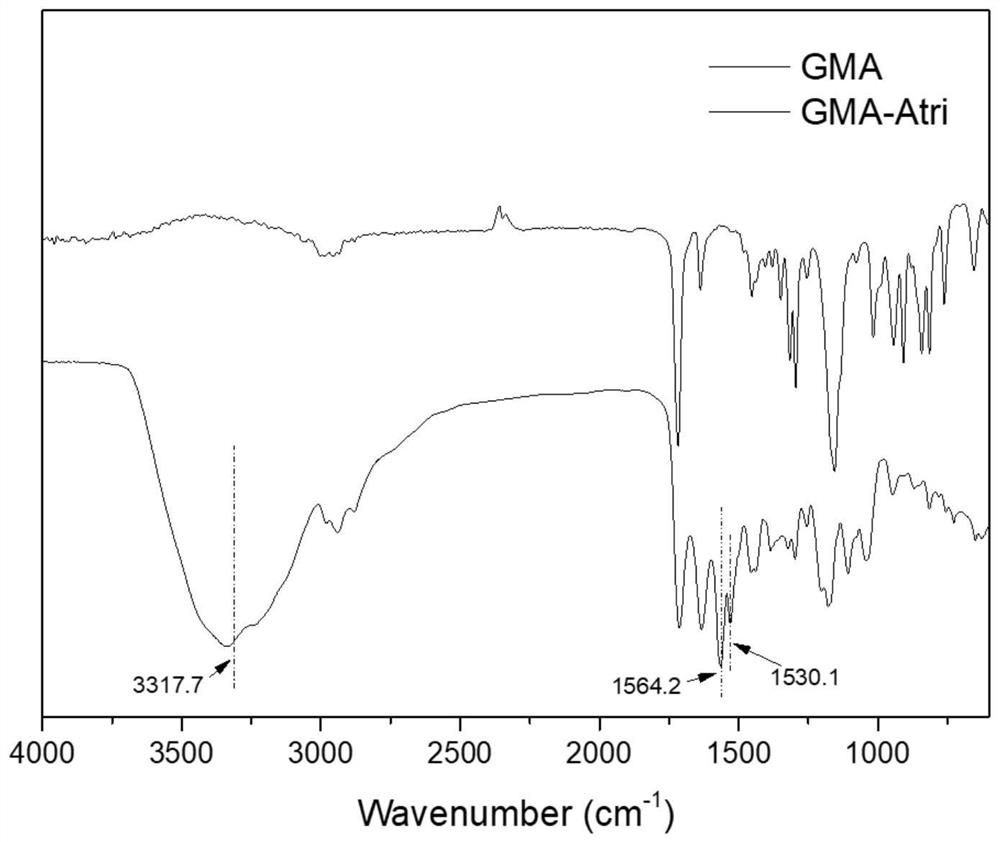

[0041] (1) 3-Amino-1,2,4-triazole (Atri) was added to isopropanol for uniform dispersion at 25°C, then glycidyl methacrylate (GMA) was added, and after 24 hours of reaction, the The solvent was evaporated to give glycidyl methacrylate-3-amino-1,2,4-triazole (GMA-Atri);

[0042] Wherein, the mass ratio of 3-amino-1,2,4-triazole (Atri) to glycidyl methacrylate (GMA) is 8:11; 34 grams of Atri are added per liter of isopropanol;

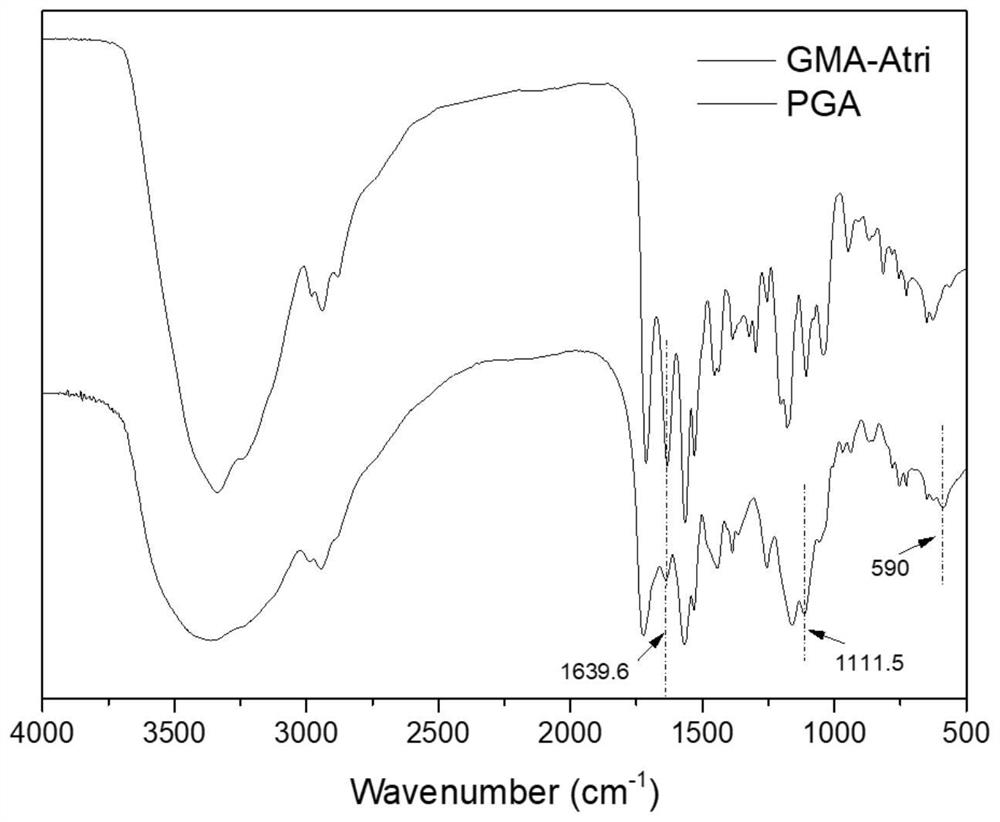

[0043] (2) Disperse GMA-Atri in deionized water at 70° C., add initiator AIBN to start the reaction, add octavinyl octasilsesquioxane (OVPOSS) after 1 hour of reaction, and react for 6 hours later, the obtained The product is precipitated in methanol, and then dried in a vacuum oven to obtain the desired azole ring-containing oligosiloxane nanofiller PGA;

[0044] Among them, the mass ratio of GMA-Atri to OVPOSS is 90:1; the mass of the added initiator is 1% of the sum of the mass of monomer 3 and monomer 4; 75 grams of GMA-Atri is added per liter of de...

Embodiment 2

[0067] Other steps are the same as in Example 1, except that Atri is replaced by Tri (1H-1,2,4-triazole). The obtained monomer 3 is GMA-Tri (glycidyl methacrylate-1H-1,2,4-triazole), and finally PGT (oligomeric siloxane organic-inorganic composite filler containing an azole ring) is obtained. The properties of the obtained composite membrane were close to those of Example 1.

Embodiment 3

[0069] The other steps are the same as those in Example 1, except that SPEEK is replaced by SPES (sulfonated polyarylethersulfone), and finally the composite membrane obtained is SPES / PGA-X. The properties of the obtained composite membrane were close to those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com