Dry cleaning, water washing and drying all-in-one machine sharing one clothes washing rotary cage

A technology of washing and drying and integrated machine, which is applied in the field of drying integrated machine, dry cleaning, and water washing, and can solve the problems that the dry cleaning dryer cannot meet the requirements of washing and drying, and the impact of dry cleaning and drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

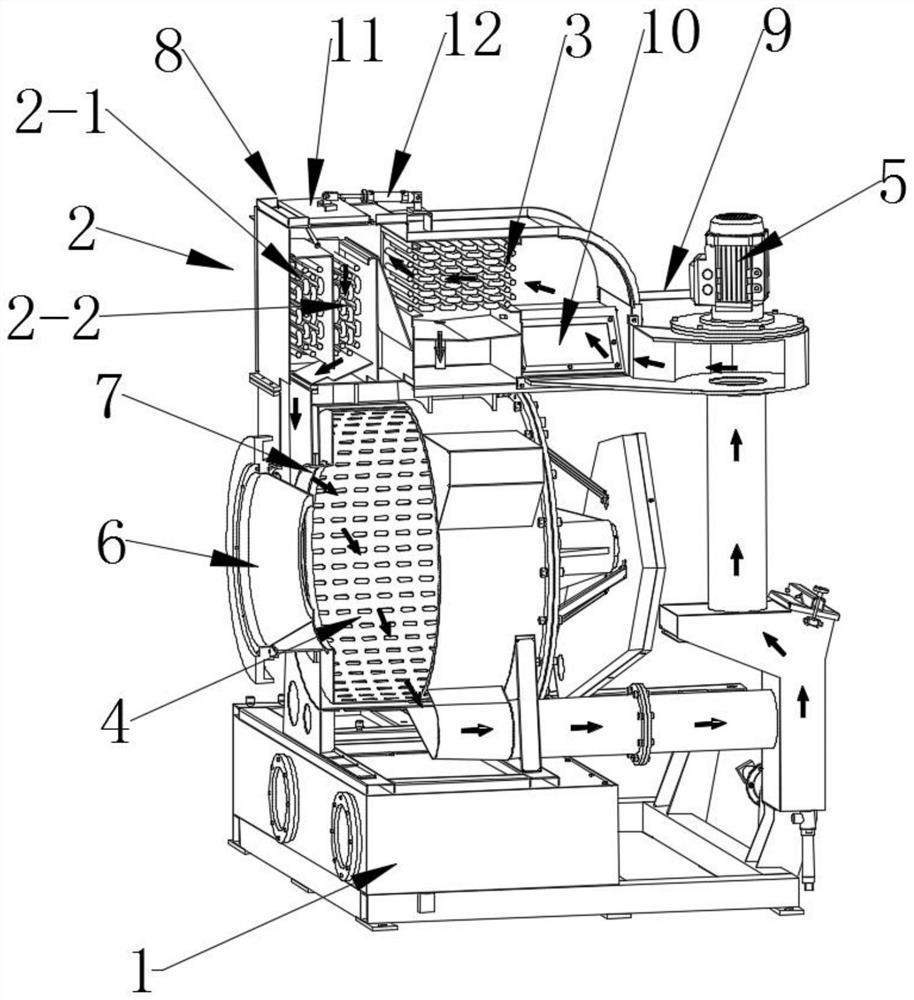

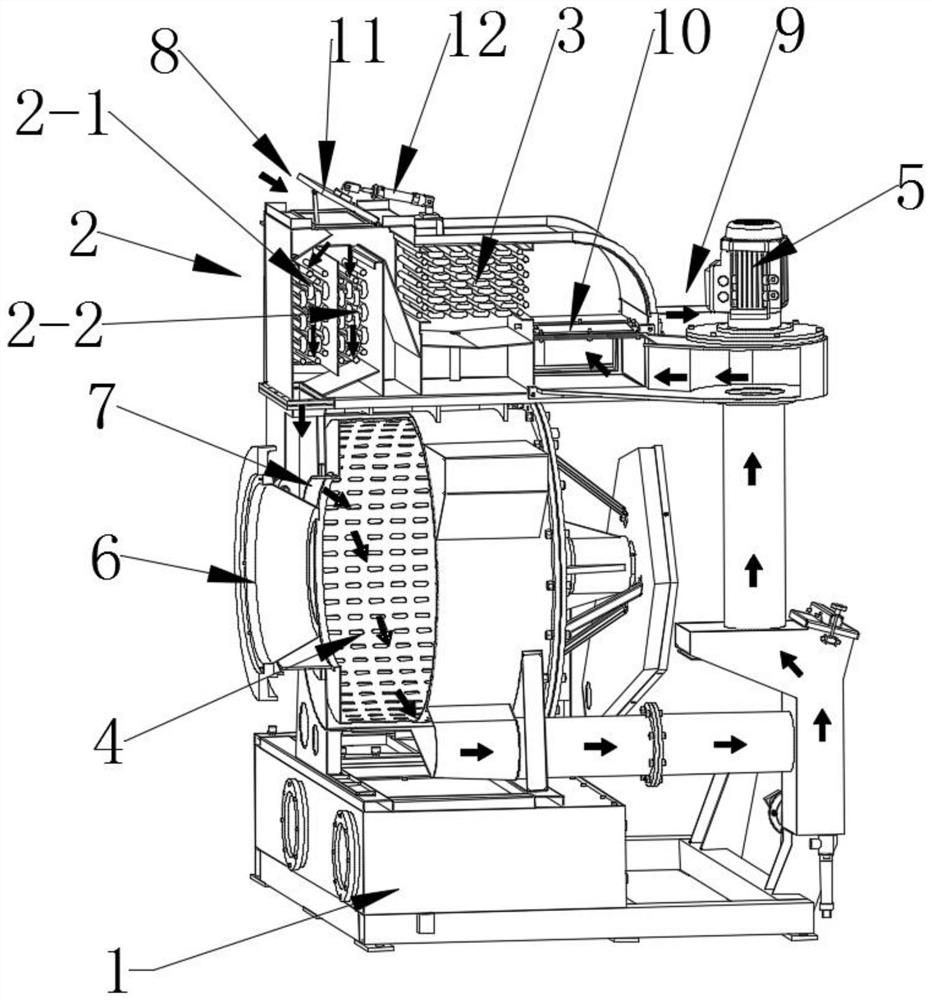

[0015] Such as figure 1 and figure 2 Shown is an integrated machine for dry cleaning, water washing and drying that shares a laundry tumbler, including a base 1, a heater 2, a condenser 3, a laundry tumbler 4, a circulating fan 5, a machine door 6 and a number of circulation pipelines, Wherein: the laundry tumbler 4 is set horizontally forward on the base 1, the door 6 is closed at the opening of the laundry tumbler 4, the door 6 is set in the shape of a circular platform, and the small round end surface of the door 6 extends To the inside of the laundry tumbler 4, an annular hot air inlet 7 is arranged between the conical surface of the machine door 6 and the inner wall of the laundry tumbler 4;

[0016] The heater 2 and the condenser 3 are respectively arranged above the laundry tumbler 4; the top of the heater 2 is provided with an air i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap