Novel underground non-standard high-pressure flow meter

A flow meter, non-standard technology, applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., can solve the problems of exceeding the measurement range, difficult to guarantee accuracy, and non-measurement, so as to improve the measurement accuracy , Improve measurement accuracy and reduce measurement deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

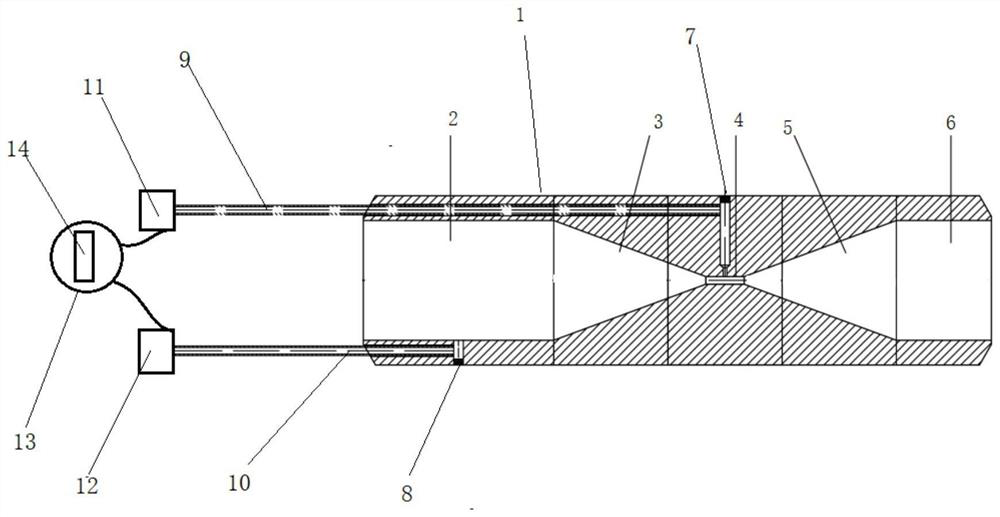

[0024] as attached figure 1 Shown:

[0025] The present invention provides = a new type of downhole non-standard high-pressure flowmeter, including a pipeline body 1, an inlet cylinder section 2, an inlet conical constriction section 3, a throat pipe 4, an outlet conical constriction section 5, an outlet cylinder section 6, a negative pressure take-off Pressure port 7, positive pressure port 8, negative pressure pipe 9, positive pressure pipe 10, first pressure transmitter 11, second pressure transmitter 12, flow display instrument 13, display 14, all The inside of the pipe body 1 is provided with an inlet cylindrical section 2, an inlet conical constriction section 3, a throat 4, an outlet conical constriction section 5, and an outlet cylindrical section 6, and the right side of the inlet cylindrical section 2 is connected to the inlet conical constriction section 3 The right side of the inlet conical constriction section 3 is connected to the throat pipe 4, the right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com