Corner smooth transition method based on track mode

A smooth transition and corner technology, applied in the direction of instruments, digital control, control/regulation systems, etc., to achieve the effects of improving efficiency, avoiding incentives, and improving processing efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

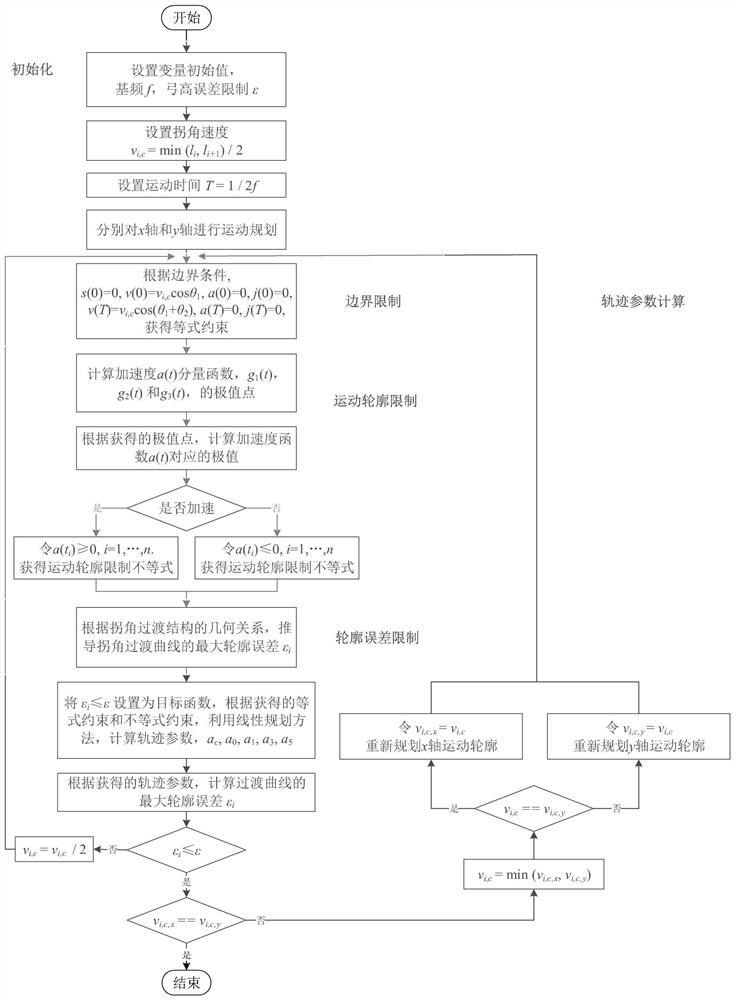

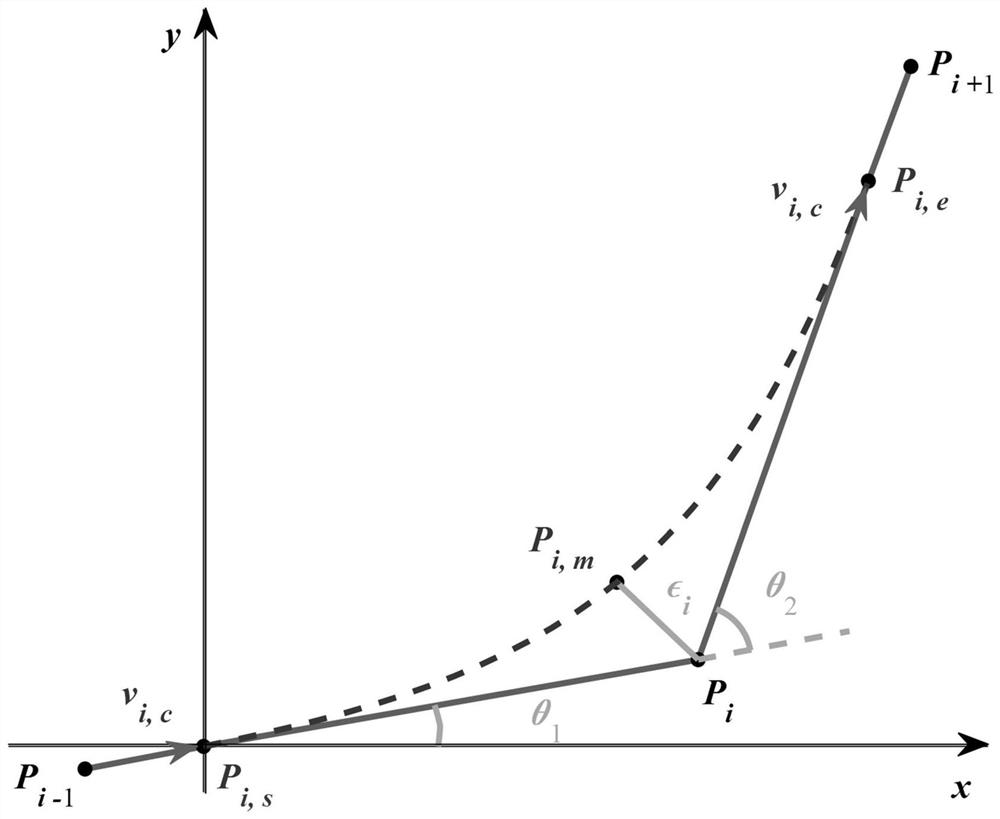

[0058] The invention discloses a corner smooth transition method based on a trajectory mode. According to a given fundamental frequency, the trajectory mode is used to complete the corner transition curve construction and axis speed planning in one step, effectively improving the smoothing efficiency and avoiding Mechanical structure resonance; at the same time, since the generated shaft kinematics profile is very smooth and contains only three low-frequency components, it can significantly reduce the high-frequency components contained in the driving force / torque, avoid excitation of the system vibration mode, and achieve high-speed High quality processing.

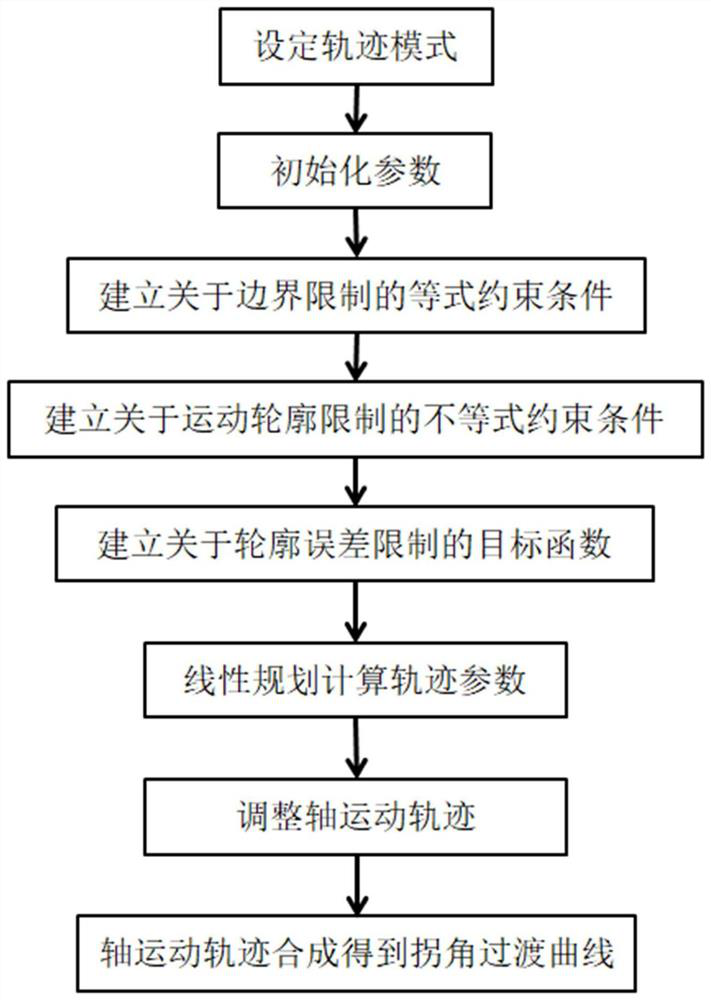

[0059] Such as figure 1 As shown, the present invention proposes a corner smooth transition method based on trajectory mode, which solves the processing efficiency and accuracy problems of complex curves and sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com