Sounding device and electronic equipment with same

A sound-generating device and substrate technology, applied in the directions of sound-generating equipment, electrical components, instruments, etc., can solve problems such as sound leakage, and achieve the effects of avoiding sound leakage, preventing swing, and improving vibration stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

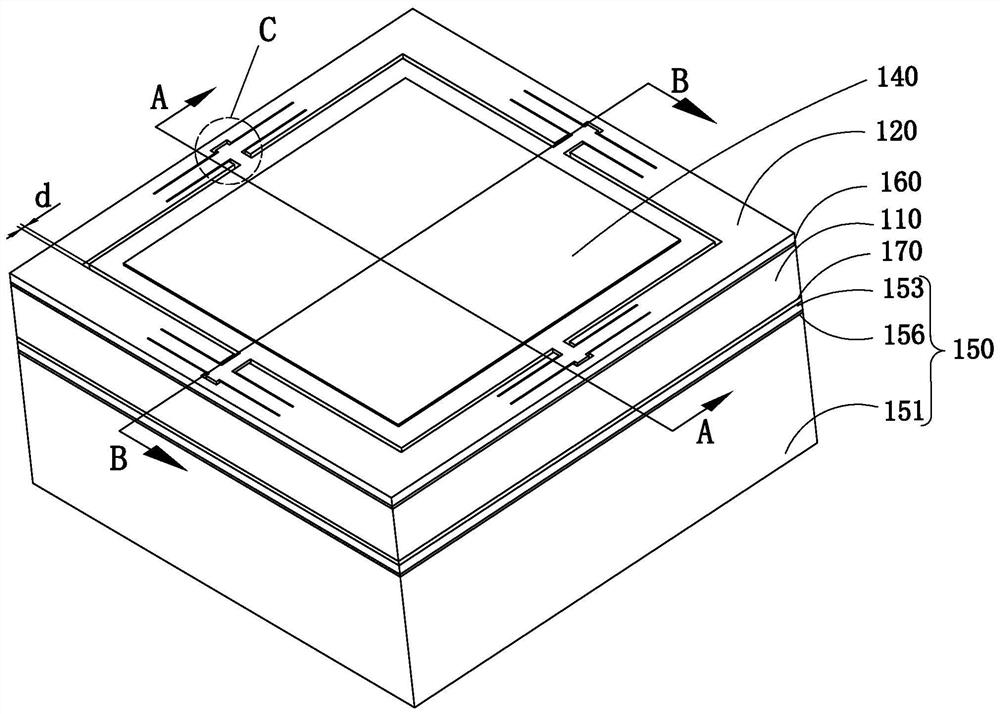

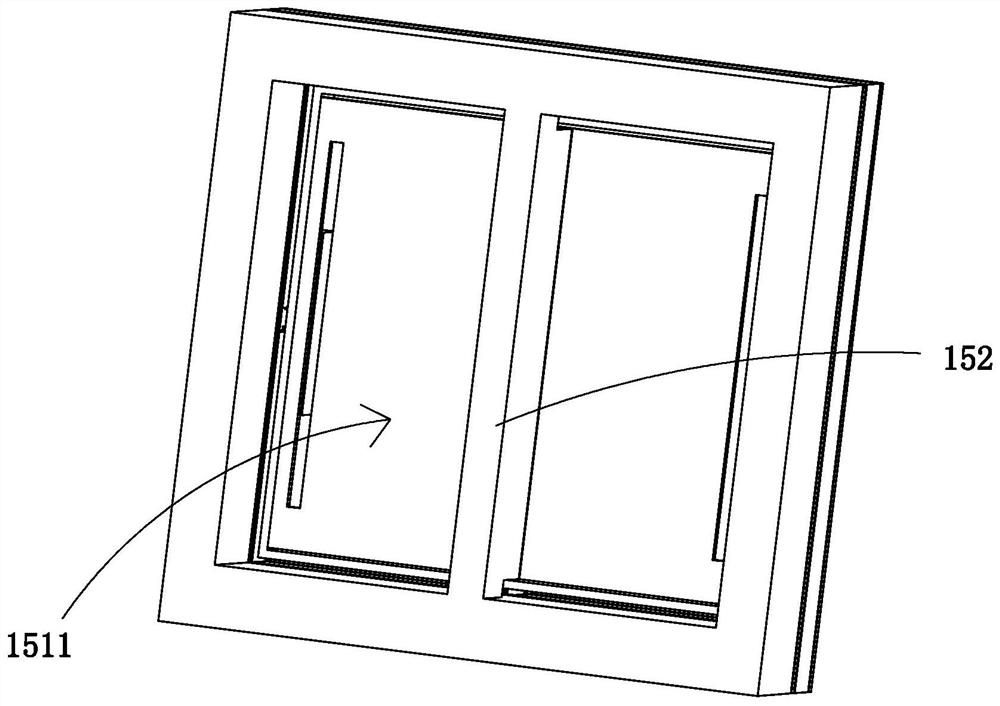

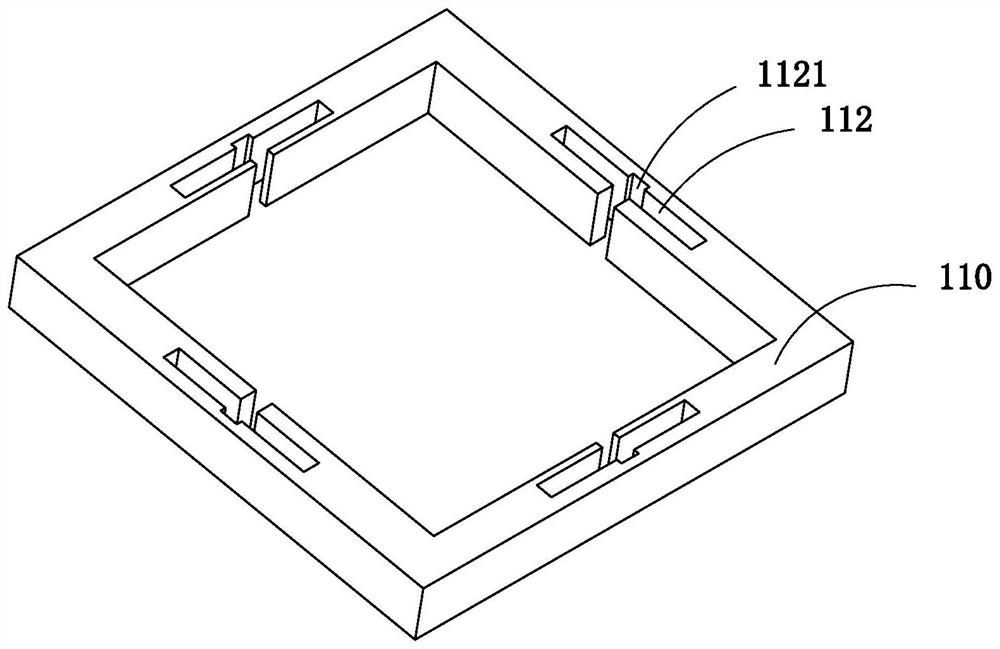

[0033] refer to Figure 1-8 , the present invention discloses a sounding device, comprising a first substrate 110 with a first through hole in the center, a vibrating layer 120 arranged above the first substrate 110, a vibrating layer 120 connected to the vibrating layer located in the first through hole The connecting piece and the driving device for driving the vibrating layer 120 to vibrate. The vibrating layer 120 includes a fixing part 121 located above the first base body 110 and fixed to the first base body 110, a diaphragm 124 suspended above the first through hole, and a connecting diaphragm 124 and the elastic connecting member 123 of the fixing part 121; the elastic connecting member 123 includes a connecting part 1231 for connecting the diaphragm 124 and an elastic part 1232 capable of moving along the central axis direction of the diaphragm 124, and one end of the connecting part 1231 is connected to the diaphragm 124, the other end of the connecting part 1231 is ...

Embodiment 2

[0059] refer to Figure 9 -14, the sound generating device of the second embodiment is adjusted on the basis of the first embodiment. Specifically, the size of the annular connecting member 230 , the structure of the diaphragm 224 covered by the annular connecting member 230 , and the structure of the second driver 250 are adjusted.

[0060] In this embodiment, the cross-sectional size of the annular connecting member 230 is reduced, which is smaller than the size of the diaphragm 224 and also smaller than the cross-sectional size of the third through hole 2511 .

[0061] In order to increase the strength of the diaphragm 2241 extending from the annular connector 230 to the edge of the diaphragm 224, preferably, the thickness of the diaphragm 2241 in this area is increased, and in order to increase the vibration amplitude of the diaphragm above the second through hole 231, preferably, To reduce the thickness of the diaphragm in this part of the region, in order to increase th...

Embodiment 3

[0066] refer to Figure 15 -17. In this embodiment, the annular connector 330 is designed in a circular shape, and the center of the second base 351 is provided with a circular third through hole 3511, and the diameter of the third through hole 3511 is larger than the diameter of the annular connector 330 , the cantilever driving plate 353 fixedly connected with the second base 251 is arranged on the second base 351 symmetrically distributed about the central axis, the number of the cantilever driving plate 353 is at least 2, the free end of the cantilever driving plate 353 is the driving end, and the driving The end is connected with the ring-shaped connecting piece 330, and the driving end drives the ring-shaped connecting piece 330 to move along the direction of the central axis.

[0067] A piezoelectric unit is disposed on each cantilever driving plate 353 , and a fixed end of the piezoelectric unit is disposed on the second base 351 .

[0068] The present invention also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com