Resistive silencing device

A sound-absorbing device and resistive technology, which is applied in the direction of sound-absorbing devices, exhaust devices, engine components, etc., can solve the problems of sound-absorbing material burning and affecting driving safety, etc., to improve sound-absorbing performance, high heat transfer efficiency, and solve porous sound-absorbing layer Effects of combustion and deformation of porous sound-absorbing layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

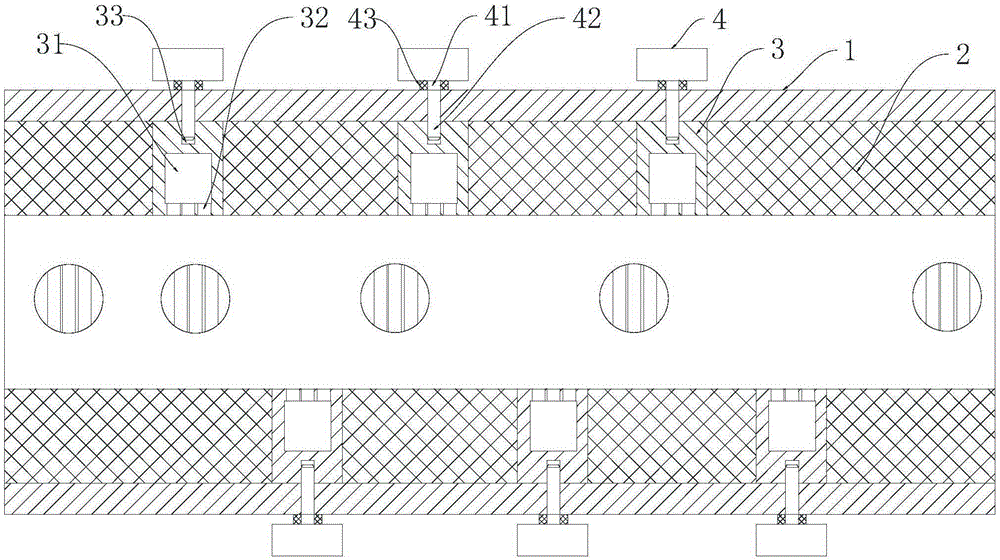

[0022] Such as figure 1 As shown, the resistive sound-absorbing device includes a cylinder body 1, a porous sound-absorbing layer 2 and an inner heat-conducting block 3; the porous sound-absorbing layer 2 is arranged on the inner surface of the cylinder body 1, and a plurality of inner heat-conducting blocks 3 are embedded in the porous sound-absorbing layer 2, The inner heat conduction block 3 is in contact with the inner surface of the cylinder body 1 .

[0023] When working, sound waves enter the cylinder body 1, and a part of the sound energy is converted into heat energy by friction in the pores of the porous sound-absorbing layer 2 and dissipated, so that the sound waves passing through the muffler are weakened, and the heat generated during this period is transferred to the cylinder through the inner heat conducting block 3 Body 1, so that the heat can be effectively dissipated. Due to the low heat conduction efficiency of the porous sound-absorbing layer 2 , heat accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com