Infrasound airborne sound calibration device

A calibration device, airborne sound technology, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve problems that cannot meet the needs of actual use, air leakage, and difficult corrections, etc., so as to facilitate installation and realization. Airtightness, the effect of solving traceability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below with reference to the accompanying drawings and examples.

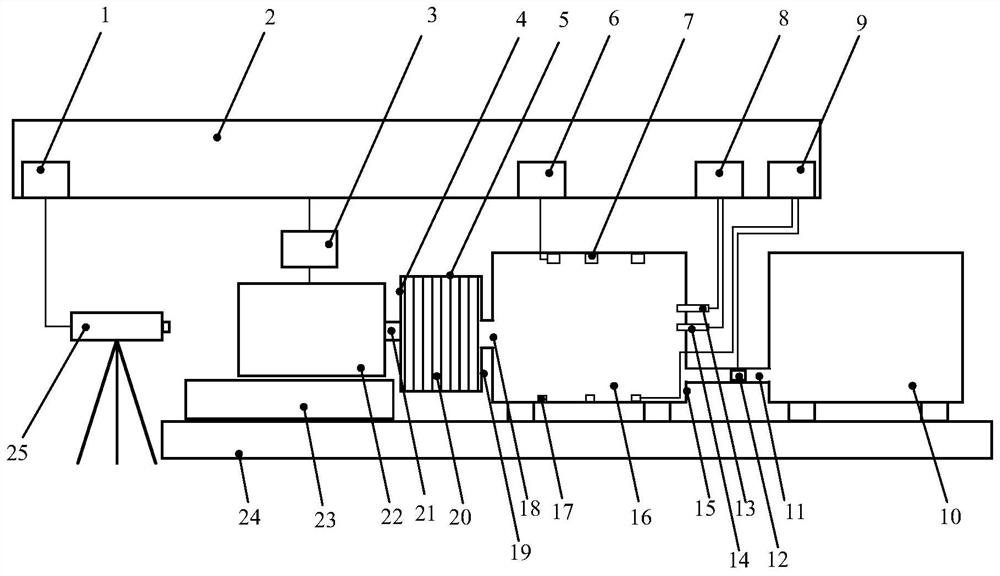

[0024] like figure 1 As shown, an infrasound air sound calibration device disclosed in this embodiment includes a motor motion system, a bellows assembly 20, a laser vibrometer 25, a sealed cavity 16, a differential pressure sensor 12, a reference cavity 10, a measurement and control system 2, Standard infrasound sensor 13 and calibrated infrasound sensor 14. The motor motion system drives the bellows assembly 20 to reciprocate through the connecting rod 21, and generates sinusoidal infrasound waves in the sealed cavity 16; the laser vibrometer 25 calculates the infrasound sound pressure level in the sealed cavity 16 by measuring the displacement of the motor moving parts, and realizes The absolute calibration of the infrasound sensor; the reference cavity 10 and the sealed cavity 16 communicate with each other through the differenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com