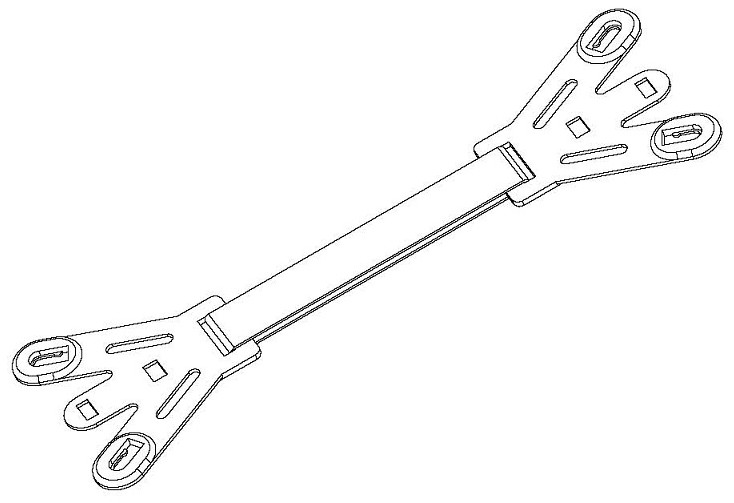

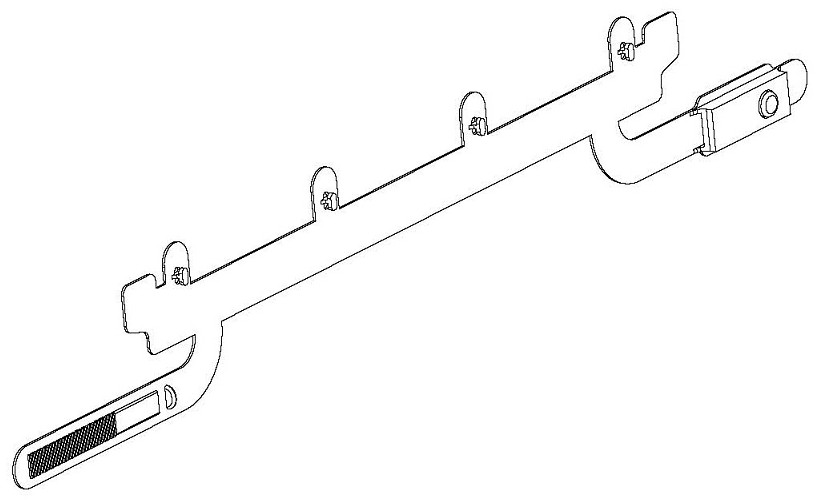

Automatic press-fitting system for safety helmet top belt and helmet hoop ring belt

A safety helmet and top strap technology, applied in hat products, clothing, applications, etc., can solve the problems of no automatic assembly device, difficult positioning, difficult automatic assembly, etc., and achieve simple structure, reduce labor costs, and realize automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

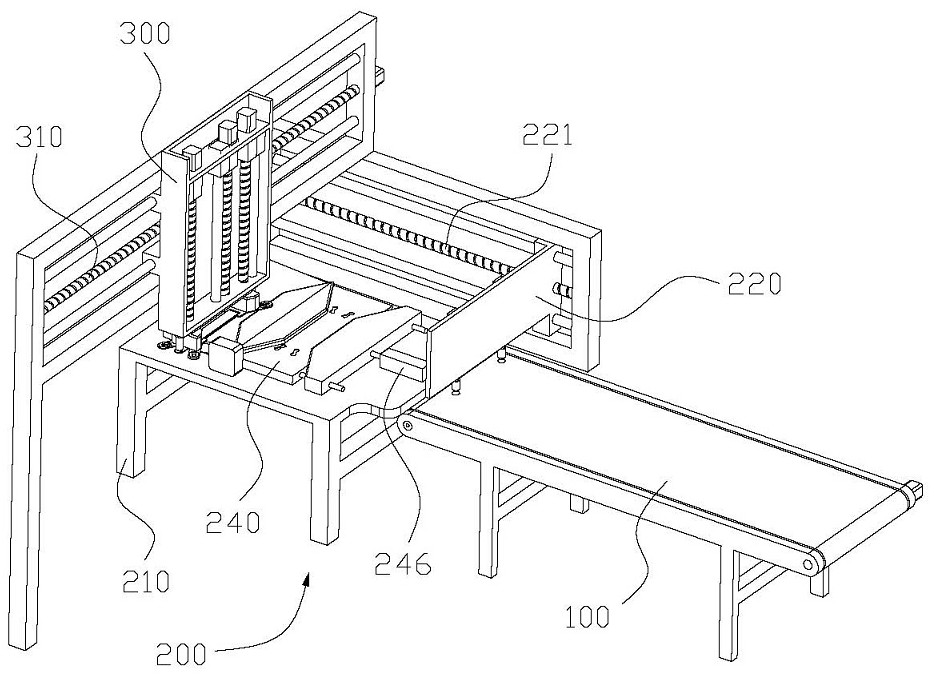

[0025] Combine below Figure 3 to Figure 18 , the present invention is described in further detail.

[0026] refer to Figure 3-Figure 8 , the present invention provides a safety helmet top strap positioning and grabbing device, including a top strap positioning device 200 and a top strap grabbing device 300; the top strap positioning device 200 includes a first base 210, a transfer unit 220, a second A camera 230 and a positioning unit 240, the first camera 230 is used to take pictures of the front and back information of the helmet top strap, and the transfer unit 220 transfers the helmet top strap transported from the conveying unit 100 to the location according to the output information of the first camera 230 On different stations of the unit 240, the positioning unit 240 flips and clamps the top strap of the helmet so as to perform positioning on the top strap of the helmet; the top strap grabbing device 300 includes a second power unit 310, a first seat body 320 , gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com